Ceramic Fiber Board Calcium Silicate Insulation Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

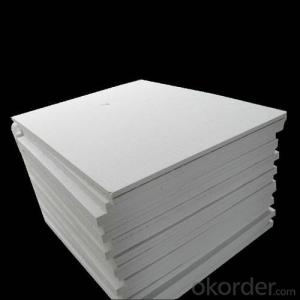

Quick Details Calcium Silicate Board for Insulation

| Place of Origin: | (Mainland) | Brand Name: | Model Number: | GS-1-003 | |

| Size: | 1200x2400,1220x2440 | Quality: | ISO9001:2000 | Package: | 10pcs/ctn |

Packaging & Delivery

| Packaging Detail: | packed with the wood pallet |

| Delivery Detail: | with in 10 days after the confirming contract |

Specifications

Calcium silicate board

High performance

Fire resistand,Waterproof

Cement sand fiber

Be professional more than 15 years

Calcium silicate board

Raw material:Tobermorite,cement,quartz sand,fiber

Sureface painting:Acrylic coating

Basic color:white

Fire rating test:Incombustible class A

Density:1.3g/cm3

Moisture content:<10%

Thermal conductive index:Average 0.24W/MK

Radiation:According with National Standards GB6566-2000

Size:1220mmx2440mmx4.5mm~22mm

KEY BENEFITS

Fire Resistant: ‘Class A’ (0 Flame / 0 Smoke)

Noncombustible: (10-minute duration)

Mold/Fungus Resistant: Does not support mold/fungus growth

Moisture Resistant: Resistant to weather, freeze/thaw & standing water

Termite/Vermin Resistant: Provides no food value to insects/vermin

Impact & Abuse Resistant: Made from durable Portland Cement

Acoustic Performance: Has a density of 77lbs/ft3

Workability: Installs quickly using standard carpentry tools and equipment

Dimensionally Stable: Exhibits excellent resistance to dimensional changes when exposed to variations in temperature & moisture

Environmentally Friendly: Composed of 28% post-industrial wood content, contains no added HCFC’s or VOC’s, no added formaldehyde or asbestos, reduces materials on the job

APPLICATIONS

WALLS

Excellent for interior & exterior walls, partitions, curtain walls, fire-stops & more

Great substrate for exterior finish materials

Abuse resistant

HEALTH & SAFETY

Our fiber cement board is formulated without asbestos, sepiolite or any inorganic fibres. When using power saws or sanders in a confined space, dust extraction equipment is recommended to control dust levels. Fixers must ensure that they work from adequate and safe platforms where necessary.

Note: All physical performance values of products of the figures may be changed dependent on the test method used.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- Sound-absorbing material:1, itself has sound-absorbing properties, porous fiber material.2, does not have sound-absorbing material, but processed into sound absorption structure.Common sound-absorbing materials are: polyester fiber sound-absorbing board, trough wood sound absorption board, hole wood sound-absorbing board, recycled wood sound-absorbing board, the latest is Dr. sound, high temperature ceramic sound-absorbing board, a fire prevention, water quality, hard environmental protection

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q: What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber fireproof plate, the density of 350-400Kg/m ceramic fiber board, fand; density above fand 400Kg/m.

Send your message to us

Ceramic Fiber Board Calcium Silicate Insulation Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords