High Density Ceramic Fiber Calcium Silicate Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details : Calcium Silicate Board with High Density

| Place of Origin: | (Mainland) | Brand Name: | Model Number: | CSB | |

| Density: | 1.10-1.5g/cm3 | Material: | Cement, Calcium oxide, silica sand, reinforcing fibers | Fireproof Property: | Non-combustible material meets Class A (GB/8624-1997) |

| Maxim Fireproof Property: | 240min (GB/9978-1999) | Moisture Content of Factory: | <10% | Thermal Conductivity Coefficient: | Averagely, 0.22w/MK(jc/T564) |

| Sound Proof Volume: | 45db(GBJ75-84) | Anti-bending Strength: | >16Mpa(GB/T7019-1997) |

Packaging & Delivery

| Packaging Detail: | with pallet |

| Delivery Detail: | Within 15 days after receiving your prepayments |

Specifications

High Density Calcium Silicate Board

1: Factory Price

2: High quality

3: Fast Delivery

4: Competitive Service

High Density Calcium Silicate Board

1: Product Description

Calcium silicate board is mainly made from siliceous material and lime refractory and reinforcing fiber through the process of slurrying, forming, high pressure steam curing, drying, surfacing, etc. When siliceous material and lime refractory is mixed together under high temperature and high-pressure condition, tobermorite (C5S6H5), a kind of crystalloid, will come into being, which has extremely stable performance. So Aimite board whose main component is just this kind of crystalloid, has good fire retardancy, moisture resistance, high strength, durability, low deformation rate, heat insulation and so on.

2: Good Performance of Board

1:Fire retardancy meets Class A in line with GB862 fire proof testing standard. It is incombustible and no poisonous gas is released when it is on fire.

2:Such case, like deformation, opening, going mouldy, rottenness, will never occurred in any circumstance.

3:Comparing with traditional partition, it bears remarkable performance in price ratio.

4:The board bears low thermal conduction performance, which makes it of better property of heat insulation and heat preservation.

5:It can stand the eroding of acid and alkaline solution, thus it can widely used in chemical, spinning, printing and dyeing industry.

6:Environmental friendly board series are totally freely of poisonous fiber, no poison, no-toxic radiation.

7:It can be processed by normal tools and installed by normal suspending, partition technique without any special technique.

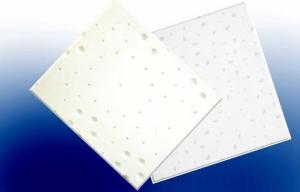

8:With high performance of sound-absorbing effect, is an ideal indoor partition or suspending ceiling material.

9:It bears good performance of high-strength, high anti-impact, nail and screw holding ability. Strength of 6mm thickness board is far excels that of ordinary paper faced gypsum board of 9.5mm thickness.

10:Board surface is compatible with all kinds of dope, wallpaper and tiles, etc to reach perfect decorative effect.

3: Technical Data

Material | Cement, Calcium oxide, silica sand, reinforcing fibers |

Fireproof Property | Non-combustible material meets Class A (GB/8624-1997) |

Maxim Fireproof Property | 240min (GB/9978-1999) |

Density | 1.10-1.5g/cm3 |

Moisture Content of Factory | <10% |

Thermal Conductivity Coefficient | Averagely, 0.22w/MK(jc/T564) |

Sound Proof Volume | 45db(GBJ75-84) |

Anti-bending Strength | >16Mpa(GB/T7019-1997) |

Water Absorption Rate | <20% (GB/t7019-1997) |

Frost Resistant Property | No damage phenomenon, such as delamination, appears after 25 times circle of freezing and thawing. |

Waterproofness | After 24 hours, no water-drop emerge |

Radiation | Conform to standard (GB/6566-2001) |

4: Main Application and Operation Place

Main Application | partition, suspended ceiling tiles, aluminum composite panels, hanging panel on exterior wall, guard wall, free access floor (raised floor), desktop panel, billboard, materials wardrobe, washing closed panel, fire resistant air-duct |

Operation Place | |

CommercialBuilding: | Commercial Store, entertainment venues, shopping centers, hotel

|

IndustryBuilding: | Factory, warehouse |

ResidenceBuilding: | Newly type residence, residence renovation, exterior wall thermal insulation panel. |

Public Places: | Hospital, theater, railway station |

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- Sound-absorbing material:1, itself has sound-absorbing properties, porous fiber material.2, does not have sound-absorbing material, but processed into sound absorption structure.Common sound-absorbing materials are: polyester fiber sound-absorbing board, trough wood sound absorption board, hole wood sound-absorbing board, recycled wood sound-absorbing board, the latest is Dr. sound, high temperature ceramic sound-absorbing board, a fire prevention, water quality, hard environmental protection

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q: What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber fireproof plate, the density of 350-400Kg/m ceramic fiber board, fand; density above fand 400Kg/m.

Send your message to us

High Density Ceramic Fiber Calcium Silicate Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords