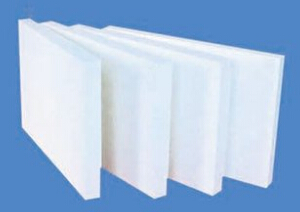

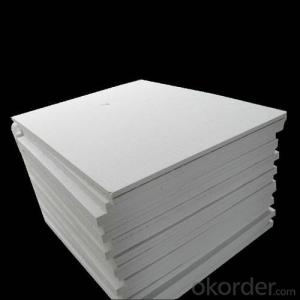

Vacuum Formed Ceramic Fiber Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The boards are high performance insulation products manufactured from ceramic fiber (or with alumina fiber) and binders, with unique shot removing and vacuum forming process, provide excellent high temperature stability, extra low thermal conductivity, high compressive strength.

The boards can be easy to saw, drill and die-cut, used as hot-face or back-up thermal insulation in various high temperature applications in furnaces, kilns etc. Additional hardness and strength can be reached with post treatments. Available in variety of compositions, densities, sizes and post treatments combinations.

Classification Temperature 1260°C, 1400°C, 1430°C, 1500°C, 1600°C

Density: 280-650kg/m3

Advantages

► High temperature stability

► Low thermal conductivity

► Low heat storage

► Non-wetting to molten aluminium

► Good flexural and compressive strength

► Close tolerance with excellent surface finish

► Easy to cut, drill or saw

Availabilities

► Thickness: 5-125mm

► Dimension: 900 x 600mm, 1000 x 600mm,

1200 x 1000mm

Post Treatments

► DN: Dried Normal

► SH: Surface hardened

► CH: Completely hardened

► FN: Fired

► FS: Fired and surface hardened

► FC: Fired and completely hardened

Applications

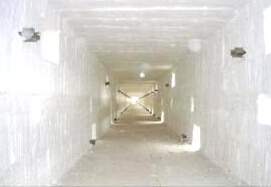

► Furnace linings

► Kiln furniture

► Hot gas duct linings

► Refractory backup insulation

► Launder insulation

► General molten metal contact

► Fire protection systems

► Glass tank side and wall insulation

► Expansion joint material

► Combustion chamber insulation

► High temperature gasket and seals

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board is made of continuous production, water production line and advanced technology, ceramic fiber board produced with smooth surface, accurate size, good toughness, can be arbitrarily cut, good insulation effect and other performance characteristics.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Volume density is low: the density of the ceramic fiber lining is about 25% of the lining of the light heat insulation brick, about 10% of the lining of the light pouring material; adopting the fiber lining can greatly reduce the steel structure load of the furnace and prolong the service life of the furnace lining.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- The theory on the absorption coefficient is the best sound-absorbing board sound-absorbing effect 1 (all suck, no reflections), but in reality, this material does not exist (black holes in the universe are the sound absorption coefficient is 1, which is completely absorbed)

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board common specifications are: 600*400, 900*600, 1000*600 and 1000*1200mm, thickness 10/20/25/30/40/50mm, thinnest can do 6mm.Depending on the temperature range, it can be divided into:Common ceramic fiber board HLGX-164Standard ceramic fiber board HLGX-264High purity ceramic fiber board HLGX-364High alumina ceramic fiber board HLGX-464Ceramic fiber board containing zirconium HLGX-564

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Ceramic fiber board is a kind of ceramic fiber cotton produced by injection technology. It is made by continuous production and advanced technological production line.

- Q: What are the uses of ceramic fiber boards?

- Ceramic fiber board is the main use of heat insulation, fire protection, insulation to use, but also with sound absorption, noise reduction, thermal shock resistance and so on. Ceramic fiber board is mainly used in all kinds of furnace lining insulation, kiln wall lining insulation, metallurgical industry furnace fire, aluminum reduction tank, refractory brick backing.

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- 1, high compressive strength, long service life; 2, low heat capacity, low thermal conductivity;3, non brittle material, good toughness;4, accurate size, good flatness;5 、 easy to cut and install, easy to construct;6, excellent wind erosion resistance;7 、 continuous production, uniform distribution of fiber, stable performance.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber fireproof plate, the density of 350-400Kg/m ceramic fiber board, fand; density above fand 400Kg/m.

Send your message to us

Vacuum Formed Ceramic Fiber Boards

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords