Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. 2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

3.Galvanized Steel Coil Images

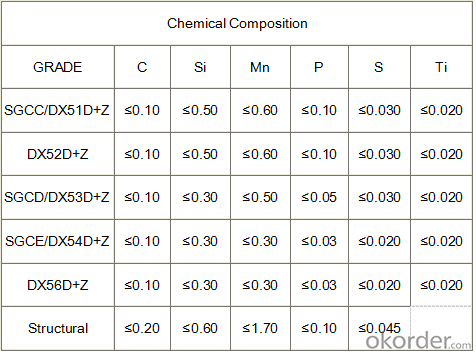

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

- Q: I'm building a single-speed commuter bike and I was wondering what the advantages and disadvantages of steel and alloy wheels are. Any experts out there who can give me specifics for each kind?

- Steel wheels are at the lowest cost and quality end of bike equipment. If you're even thinking of buying a cheapo bike with steel wheels - don't. Steel wheels are poor quality and therefore weaker than an OK alum rim. They are heavier, braking isn't as good, won't stay true as long. Alum wheels are extruded, not cast, and are better in every way. They cost more is the only down side.

- Q: Can steel coils be coated with organic materials?

- Yes, steel coils can be coated with organic materials. Organic coatings such as paints or varnishes can be applied to steel coils to provide protection against corrosion, improve aesthetics, or add other desired properties.

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: What are the common industry standards for steel coils?

- The common industry standards for steel coils vary depending on the region and specific application. However, there are several widely recognized standards that are commonly used in the steel industry. One of the most commonly referenced standards for steel coils is the American Society for Testing and Materials (ASTM) standard. ASTM has developed a wide range of specifications for different types of steel coils, such as hot-rolled, cold-rolled, and galvanized coils. These specifications outline various mechanical and chemical properties that the steel must meet, as well as dimensions, tolerances, and testing requirements. In addition to ASTM, other international organizations such as the International Organization for Standardization (ISO) and the European Committee for Standardization (EN) have also established standards for steel coils. ISO standards, such as ISO 3574 and ISO 5952, provide guidelines for the general requirements, dimensional tolerances, and mechanical properties of steel coils. Similarly, EN standards, such as EN 10130 and EN 10131, specify the characteristics and tolerances for cold-rolled steel coils. Furthermore, industry-specific organizations and associations may have their own standards for steel coils. For example, the American Iron and Steel Institute (AISI) has developed specific standards for different types of steel products, including coils. These standards cover various aspects such as chemical composition, mechanical properties, and surface finish. It is important to note that steel coil standards can also be determined by the end-use application. Industries such as automotive, construction, and manufacturing may have specific requirements that go beyond the general standards. In such cases, customers and manufacturers may refer to industry-specific standards or work together to define custom specifications. Overall, while there are several common industry standards for steel coils, it is crucial to consult the specific standards and requirements applicable to the region and application in question to ensure compliance and quality.

- Q: How are steel coils used in the manufacturing of automotive fenders?

- Steel coils are used in the manufacturing of automotive fenders by being shaped and formed into the desired fender design. The coils are cut and stamped into specific shapes, then undergo a series of bending, welding, and finishing processes to create the final fender product. The strength and durability of steel make it an ideal material for fenders, providing protection to the vehicle's wheels and body in case of collisions or impacts.

- Q: What is the role of steel coils in the production of pipes and tubes?

- Steel coils play a crucial role in the production of pipes and tubes as they serve as the primary raw material. These coils are unwound and undergo various processes such as cutting, bending, and shaping to form the desired pipe or tube shape. The steel coils provide the necessary strength, durability, and structural integrity to the final product, ensuring that pipes and tubes can withstand high pressure, corrosion, and other demanding conditions.

- Q: I Don't have a Oxy act. torch but can Get a Propane one. The finished part(s) are .375 x .550 x .185

- I think 12L14 is NOT heat hardenable, because it is low-carbon. You may try heating and quenching it, but it won't harden much. It can be hardened by cold-working - drawing or rolling processes. However, these are usually done by the material manufactures, and most machine shops do not have the capability to do this in house. Can you try 1144 steel instead? 1144 is medium-carbon (0.44%), and heat treatable. It is also free machining grade like 12L14. Other medium carbon steels are also heat hardenable: 1040, 1050, etc.

- Q: i need flint and steel. are there common household items i can get the flint and the steel from????

- no common flint and steel in the house === you need to buy a Boy Scout - flint and steel fire starter kit === or a BIC lighter ... the other thing is a small jar filled with water [[ capped and water level near the top.]] hold the water-jar over some

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- I loved the new interpretation in Man of Steel Superman Returns got very poor reviews in the beginning, and as the hatred has worn off and fans have been the only ones voting, the score has moved up. As fond as I am of Christopher Reeves, his version was a touch campy. I much prefer the serious treatment.

- Q: How are steel coils used in the production of storage tanks and silos?

- Steel coils are an essential component in the production of storage tanks and silos due to their strength and durability. These coils are typically made from high-quality steel and are processed through various manufacturing techniques to attain the desired thickness and shape. In the production process, steel coils are first uncoiled and then cut into specific sizes and lengths to meet the requirements of the storage tank or silo design. The coils are then shaped into cylindrical sections, using bending and rolling machines, to create the main body of the tank or silo. Once the desired shape is achieved, the coils are welded together to form a continuous and secure seam. This welding process ensures that the tanks and silos are leak-proof and can withstand the pressure exerted by the stored materials. Furthermore, steel coils also play a crucial role in reinforcing the structure of storage tanks and silos. They are often used to create the roofs, bottoms, and other structural components of these storage units. The strength and resilience of steel make it ideal for withstanding the weight of the stored materials and any external forces that may be exerted on the tank or silo. Additionally, steel coils can be coated or treated with protective materials to enhance their resistance to corrosion and extend their lifespan. This is particularly important for storage tanks and silos that are used to store corrosive substances or are exposed to harsh environmental conditions. Overall, steel coils are a fundamental element in the production of storage tanks and silos, providing the necessary strength, durability, and structural integrity required for these storage units.

Send your message to us

Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords