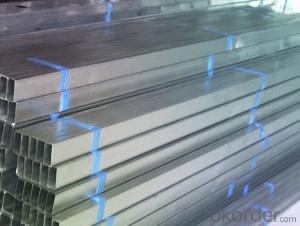

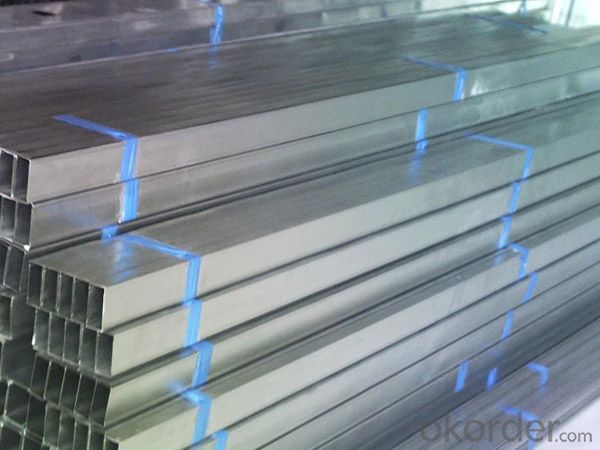

Galvanized Steel Profiles for Gypsum Board Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Lightgage Steel Joist

1.according to standard of GB/T11981-2001

2.adopting advanced domestic equipment

3.modern technique

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

Features of light steel joist: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly.

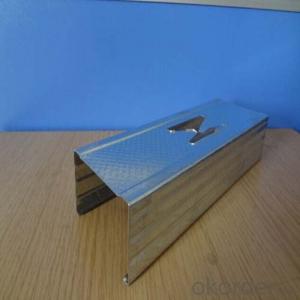

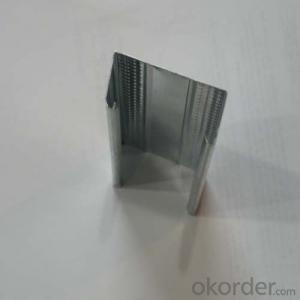

Method to test the keel's quality

1. look. Appearance smooth, no spots.

2. galvanized thickness: 80g/m2( qualified), 100g/m2( A grade), 120g/m2 ( A+ )

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

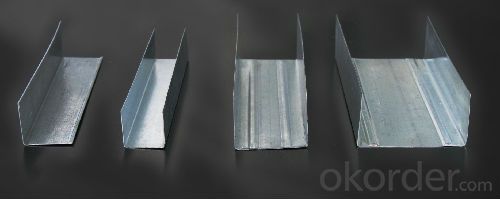

3.Image

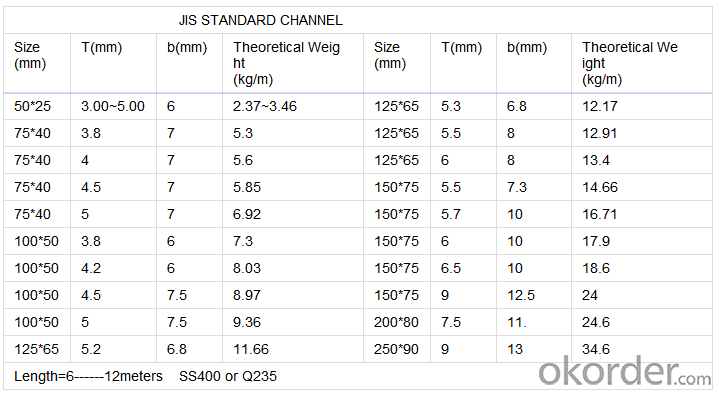

4.Detailed Specification

(1)Standard: ASTM, JIS

(2)Steel Grade: Q195

(3)Width :600mm-1500mm

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

5.FAQ

Hot rolled galvanized steel strip

1. thickness: 0.18mm - 1.5mm

2. width: 20mm - 580mm

3. material: Q195, Q195L, Q235

4. Origin of China

5. Package: export seaworthy packing

6. Galvanized or zinc

7. coil weight: 100kg-1000kg /coil

- Q: Light steel keel gypsum board modeling ceiling

- Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel.

- Q: Please give valid certificate, thank you! The

- The keel of the ceiling needs to be re-examined: Detection parameters Keel: size deviation, mechanical properties; Accessories: size deviation, mechanical properties. Keel ceiling project quality acceptance project: Ceiling elevation, size, from the arch and shape should meet the design requirements. Test method: observation; scale inspection. The material, variety, specifications, regiment and color of the facing material should meet the design requirements. When the facing material is a glass plate, use safety glass or take reliable safety measures. Inspection method: observation; check product certificate of competency, performance testing report and admission inspection records. Finishes should be tightly installed. The overlapping width of the facing material and the keel should be greater than two-thirds of the width of the keel. Test method: observation; hand pull check; scale check. Boom, keel material, specifications, installation spacing and connection should meet the design requirements. Metal boom, keel should be surface corrosion treatment; wood keel should be anti-corrosion, fire treatment. Inspection methods: observation; foot check; check product certificate of competency, admission acceptance records and hidden engineering acceptance records.

- Q: Light steel keel ceiling one square meter how much money

- 1, installed boom When the floor is a prefabricated board, the hoisting hooks of the suspension boom are embedded in the slit, as long as the upper end of the boom can be bent through the hook hole. When the floor is a cast-in-place plate, it should first release the position of the embedded parts at the bottom of the floor. Use the nail to fix the embedded parts to the bottom of the floor, and bend the upper ends of the boom through the rings of the embedded parts Can be. 2, loaded big keel The large keel vertical hanging pieces, such as a number of sets of dog keel, the big keel handed up, so that the lower end of the boom into the large keel vertical hanging pieces on the hole, plus nuts initially screwed. According to the ceiling of the room in the cave from the arch height (generally take the room to ask the short span of 2: 0), calculate the big keel hanging point at the arch value, twist the nut so that the big keel arch arch, after adjustment , The big keel vertical hanging pieces fastened. 3, installed keel Will be in the keel vertical hanging pieces, such as the number on the big keel, the dragon handed up, so that the keel buckle in the vertical hanging parts of the keel. If the keel intersects with the brace, the keel is placed on the middle keel and the cross brace is in the middle of the keel. Light steel keel ceiling price and construction steps on the finished, you all understand it? For light steel keel ceiling price you can according to their own needs to buy.

- Q: Ecological wood veneer gypsum board closed light steel keel ceiling decoration drawings so what is the meaning? How to understand

- The above is just speculation in accordance with the practice only, the designer belongs to the garbage family, did not see such a "note". It is recommended to consult the designer, be confirmed, so as to avoid mistakes.

- Q: Light steel keel gypsum board ceiling lamp how to install

- This is not the most basic process? Cutter to open the downlight to buy the LED is the external spotlight effect is kind ~

- Q: Light steel keel moisture-proof gypsum board ceiling which is the grass-roots which is the surface layer?

- Grass is the light steel keel, the surface layer is moisture gypsum board.

- Q: Light steel keel paper gypsum board ceiling construction process

- 1. Process: Slide - → Install the big keel boom - → install the big keel - → install the keel - → install the keel - → install the cover cotton board - → install the pressure bar - → brush anti-rust paint 2. Pin line: According to the floor elevation line, with the ruler vertical volume to the top [shed design elevation, along the wall, the column around the ceiling height, and along the elevation of the ceiling line, draw a good line on the wall line. 3. Install the big keel boom: After playing the high level of the ceiling and the keel position line, determine the elevation of the lower end of the boom, press the big keel position and the hanging spacing, the boom without the end of the screw thread and the floor embedded rib Connection is fixed.

- Q: Light steel keel how to do secondary ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling. Any light steel keel ceiling of the multi-level ceiling and complex modeling, multi-use wood core board and light steel keel convergence.

- Q: Home decoration living room ceiling (light steel keel or wood keel) between the two, what is the difference?

- Light steel keel ceiling, from the small area of the process is harder than the wood keel, but the high flatness

- Q: Light steel keel ceiling specifications require boom length greater than 1500MM to add anti-support, what is anti-support? How to set up? The best specific construction node map, thank you!

- When the hanging length of more than 1.5m should be set anti-support, reverse support is in the case of normal boom, from the lower end of the boom oblique ceiling installation to connect a rod, rod to have a certain stiffness, and the boom to form a Solid triangular. To prevent the ceiling in the air pressure when the upward deformation, the formation of dome, causing damage to the ceiling. The number of anti-support should be set according to the construction plan.

Send your message to us

Galvanized Steel Profiles for Gypsum Board Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords