Galvanized Steel Coil for Lightgage Steel Joist Ceiling Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Light Steel Keel

Light steel keel Feature:

1. Strong intensity,Non-deforming

2. The unique joint design makes the installation easy, time saving

3. Easy to install, match with plasterboard

4. Used to make ceiling or partition for office, shop and other spaces

5. This type of keels looks more elegant in style

6. Rustproof, fire resistance, stainless, rust resistance and convenient application.

7. High precision, high symmetry, high close fitting.

Light steel keel Usage

Partition keel

1. C Stud: Be used for hanging plasterboard.

2. U Track: Be used for fixing C Stud, usually install along the upper and nether floor.

3. Intermediate channel: Used to increase the strength of the partition.

4. Ceiling accessories: Necessary components for the installation of steel.

Ceiling keel

1. Main keel: Bearing all the weight of the suspended ceiling.

2. Furring keel: Used to hanging plasterboard.

3. Side channel: Make sure the ceiling is fixed in a horizontal position.

4. Ceiling accessories: Necessary components for the installation of steel keel.

3.Image

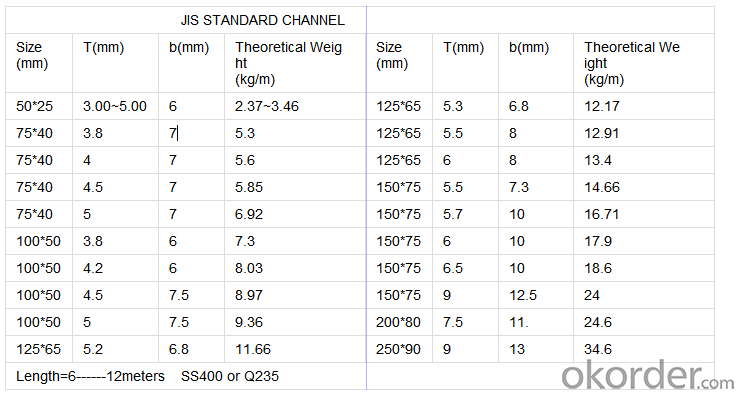

4.Detailed Specification

5.FAQ

Applications

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Metal track & Metal stud

Drywall partition channel consists of ----

Vertical U shaped light steel channel (metal track)

and horizontal C shaped light steel channel (metal stud)

If there are something unclear or some questions, pls do not feel trouble to contact us,we will try our

best to let you know our company and our products well.

- Q: What is the general ceiling of indoor ceiling?

- Upstairs copy of the good. Really quite detailed. That I also talk about it. Light steel keel wood keel aluminum buckle plate steel plate plaster board sauna board

- Q: Light steel keel ceiling The first main keel distance from the wall should be how much? To be specific.

- W fixed spacing of the boom 900-10OOmm pitch, in the event of beam and pipe fixed point is greater than the design and procedures requirements, should increase the fixed point of the boom. W is not on the ceiling, boom length is less than 10OOmm, you can use φ6 boom, if more than 10OOmm, should be used φ8 boom, should also set the reverse support. W Master's ceiling, boom length is equal to 10OOmm, you can use φ8 boom, if more than 10OOmm, should be used φ10 boom, one end of the boom with L30X30X3 angle welding (corner of the aperture should be based on boom and expansion Bolt diameter to determine), the other end can be tapped out with more than 100mm screw, you can also buy finished screw welding.

- Q: Light steel keel ceiling which brand is better

- Domestic dragon card can, foreign brands have Lafarge, Jieke is also good. Above, not advertising, on the matter only - the landlord itself is to do building materials, should not know it?

- Q: Light steel keel ceiling effect is what

- Improve the indoor environment conditions, to meet the requirements of the use of functions. Light steel keel ceiling decoration can improve the indoor light environment, thermal environment and sound environment. On the creation of indoor art environment and improve the comfort of the provision of the Pieces. Such as the room in the ceiling under the ceiling, by blocking the air to reduce the impact of the sound, you can improve the indoor sound environment; ceiling space laying insulation, insulation materials, or the use of ceiling space to form a ventilation layer, Thermal environment; light steel keel ceiling shape and color, texture, etc. can adjust the indoor light, can improve the indoor light environment. 2, beautify the space environment, improve the effect of interior decoration Pavilion decoration is more easy to be noticed, it is from the type of space, light, light, color and material, and many other aspects of rendering the environment, contrast the atmosphere, so the roof design should consider the technology and art Combined to achieve finished decorative effect. 3, adjust the volume and shape of the indoor space When the structure of the building structure surrounded by the formation of space is not ideal, the ceiling can be coordinated, unified indoor space volume and shape, enhance the integrity of the ceiling. Concealed equipment pipelines and structures Components can be used within the ceiling space to install lighting, air conditioning, ventilation, sound, fire and other equipment needed pipeline, modern buildings more and more equipment pipeline generally need to be hidden in the ceiling to make the indoor ceiling Clean and tidy.

- Q: Construction schedule of light steel keel ceiling

- How much area? What shape? Elaborate

- Q: Light steel keel ceiling and wall construction technology

- The main machine main equipment include: saws, toothless saws, nail guns, hand saws, hand plane, pliers, screwdrivers, moving, square feet, steel ruler, steel level and so on.

- Q: Ceiling twenty square meters need light steel keel how many roots

- Light steel keel ceiling material ratio does not have a standard number, generally according to the shape of the room, height related.

- Q: The construction of the lightweight steel keel gypsum board ceiling

- Note that the material can be used to mark, such as hanging bars, expansion screws, the main keel, vice keel. Aluminum plate.

- Q: PVC plastic buckle plate ceiling with what keel ah?

- There may be putty or gypsum did not dry on the latex paint

- Q: Will the light steel keel ceiling be deformed?

- Generally not Please adopt If you acknowledge my answer, please accept it in time, ~ If you acknowledge my answer, please click on the "Accept Satisfactory Answer" button ~ ~ Mobile phone questions friends in the upper right corner of the client evaluation point [satisfaction] can be. ~ Your adoption is the driving force of my progress ~ ~ O (∩ _ ∩) O, remember praise and adoption, help each other

Send your message to us

Galvanized Steel Coil for Lightgage Steel Joist Ceiling Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords