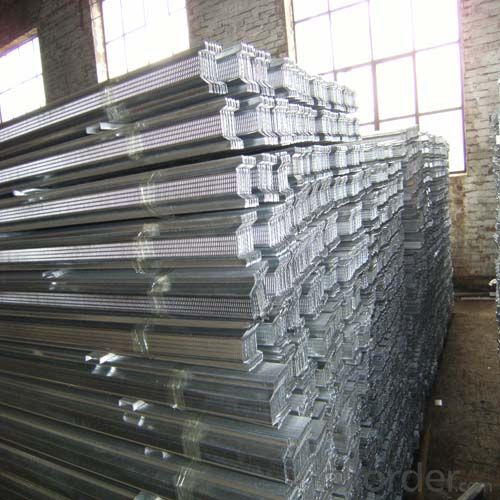

Galvanized Ceiling Drywall Steel Stud Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Discription of DRY WALL METAL PROFILE OF U CHANNEL ZINC GALVANIZED

1>adopting high-grade quality hot-dipped galvanized steel,

2>The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product.

Specification:

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Feature

(1) Ceiling solid structure, good safety performance

(2) Frame and light weight

(3) No rust, no corrosion, life is very long

(4) It can variety of shapes roofs

Product Overviews

FAQ

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method. 8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price *large quantity *honesty *good after-service

9.Certificates ISO 9001:2000 Quality management system

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- My family on the 85-year house, a lot of people in the district to do solid wood flooring, also used very good, no see who said their own floor problems. Did you knock on the wall? 24 walls are load-bearing, you can not knock, even if you want to knock, but also I-beam or channel support, the longer the wall, just the more important specifications, we are all of these houses are prefabricated panels, Direction, take the wall is absolutely can not knock, there will be a lot of dangerous risks.

- Q: What are the consequences of installing a hanging cabinet on gypsum board wall?

- You say the situation gave me the feeling you installed the location is not gypsum board wall, may be light brick. Can drill with the impact of drilling and the installation of the expansion of the bolt, not gypsum board wall can do - where the gypsum board wall can withstand the impact of the impact of drilling? Chopsticks can be used to drill the gypsum board wall, how could the expansion bolts? Or is the gypsum board wall inside filled with light brick, otherwise it is impossible to do so. In addition, if the impact of the drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon play Wear, but it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play the wood slag to - this can be seen. Based on the above analysis, I think your cabinet can be fixed, but only four screws are too little. As to how much weight? This is difficult to determine. But generally placed some clothes or slightly heavier things, should be no problem.

- Q: Shanghai light steel keel ceiling, wall quotes

- Depends on the use of good and bad materials. Ordinary ceiling also 30-40, partition 35-45, I was doing this is what the project. Can contact me. Offer

- Q: What is the light steel keel gypsum board partition? What are the characteristics?

- 1. Wall shrinkage deformation and board cracks: the reason is the vertical keel tight top and bottom keel, no extension of the amount of stretch, more than 2m long wall is not controlled deformation joints, resulting in wall deformation. The wall should be left around the gap 3mm, which can reduce the temperature and humidity caused by the deformation and cracks. 2. Light steel skeleton connection is not strong, because the local node does not meet the structural requirements, the installation of local nodes should be strictly in accordance with the provisions of the law. Nail spacing, location, connection method should meet the design requirements.

- Q: How to remove the gypsum board cut off

- To deal with the local property, to understand the removal of the area to be noted, such as the demolition of the mall will be sealed room, so that the impact of dust and garbage next door store business. And the parties to deal with more, will facilitate the back of the work.

- Q: How to install light steel keel gypsum board wall

- Light steel keel gypsum board installation should generally be through the following steps: wall line → wall construction → installation along the ground, along the top keel → installation of vertical keel → fixed door and window makeup → installation of the wall side of the gypsum board → install another side of the plaster price → seam processing → wall decoration. 1. Wall line According to the design of the wall, in the ground to release the wall bit line, and the line leads to the ceiling and side walls. 2. Wall construction First on the wall and floor, ground contact parts for cleaning, coated with interface treatment agent together, then pouring C20 concrete wall, the wall surface should be smooth, both sides should be vertical. 3. Install the edge along the top keel Along the ground, along the top keel in place, with the nail fixed, shot nail from the 900mm, the location of the nail should avoid the laying of the tube area. 4. Install the vertical keel According to the determined vertical keel spacing, along the ground, along the top keel on the line drawing line. The vertical keel is arranged by the end of the wall. When the doors and windows are provided with windows and doors, they should be arranged from one side or both sides of the door window. When the last keel from the wall of the size is greater than the provisions of the keel spacing, you must add a keel. The upper and lower ends of the keel should be fixed along with the top, along the keel with rivets or tapping screws.

- Q: Can the gypsum board be painted on the wall

- If the light can be linked to the screw with a self-tapping screw, hanging 2-3 kg should be no problem

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- Light steel keel is attached to the gypsum board, it can be seen, the installation of light steel keel spacing is based on the thickness of the gypsum board to decide. Like the 12mm gypsum board, its spacing is 450mm, according to the gypsum board to determine its spacing. Finally, in the adjustment of hanging pieces into the keel inside the appropriate rotation can be consistent.

- Q: Light steel keel wall Why do not cross brace welding with welding

- Horizontal keel is a secondary support role, the panel position is not time to adjust the location, in addition to the function of contraction expansion margin, so not allowed to link the link for the rigid.

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Focus on the ground material, the first floor of the plant decoration if the ground, a lot of plant floor decoration is not required to carry the load, then you can consider using some inexpensive decorative materials, such as terrazzo or cement flooring to do the plant floor decoration materials, Decoration to consider anti-static, then we should choose anti-static floor or anti-epoxy floor, etc. as the preferred material for the ground, there are plant floor decoration needs to load the ground, then we must do concrete in the ground floor, Concrete is divided into commercial concrete and soil concrete two, the former cost slightly higher but the quality is stable, the latter price lower quality in general, and then in the concrete base and then lay the other texture is more hard stone finishes can be.

Send your message to us

Galvanized Ceiling Drywall Steel Stud Profile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords