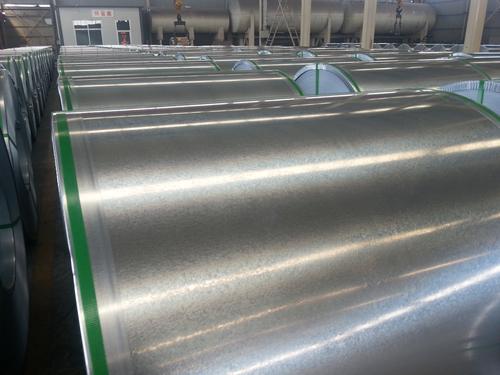

Galvanized Steel Coils SGCC, DX51D,China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: How do steel coils contribute to acoustic performance in buildings?

- Steel coils can contribute to acoustic performance in buildings by providing sound insulation and reducing noise transmission. When installed as part of a building's structure, steel coils can help absorb and dampen sound vibrations, preventing them from traveling through walls and floors. This can result in a quieter and more comfortable indoor environment, minimizing disruptions and enhancing overall acoustic quality within the building.

- Q: I am thinking about getting a cold steel tilite or a kershaw leek or possibly a buck sirus. If you have had any experience with these knives please give it to me. thanks

- You could argue that CS makes the tougher steel, but as was pointed out, none of their wares are made in the U.S. - if that doesn't matter, then go with the CS. I started with a CS Holdout II and ended up sending it back and going with a Kershaw (Ken Onion) Blur for EDC. My next knife will be a Benchmade- they are pricey but everyone I've ever spoken to about EDC knives tell me to go to Benchmade and no one else. Not one to just listen, I had to try out a few myself. Bought the wife a Kershaw Scallion...in purple, no less.

- Q: i am working in a firm that deals with steels.. so it is necessary for me to understand the chemistry of the steels from their names so that i need not memorize all the grades with their metallury.. where can i find information about this nomenclature ? please help

- For steels with a four number code like 1020, 4140 ect the first two digits are the alloying information. I think you need to memorise those. 10 steels are plain carbon steel with no alloying. 41 steels are chrome-molly. The third and forth digits are the carbon content. 1020 is 0.2% Carbon, 4140 is 0.4% carbon. I don't know if there is a system to stainless steels.

- Q: How are steel coils used in the manufacturing of transportation equipment?

- Steel coils are used in the manufacturing of transportation equipment as they provide a durable and strong foundation for various components such as chassis, frames, and body panels. These coils are typically processed and shaped into specific forms to meet the design requirements of automobiles, ships, trains, and aircraft. The high tensile strength and ability to withstand heavy loads make steel coils an essential material in the transportation industry, ensuring the safety and reliability of the vehicles and equipment.

- Q: How are steel coils tested for quality?

- Steel coils are tested for quality through a variety of methods including visual inspection, dimensional measurements, chemical composition analysis, and mechanical testing. These tests ensure that the steel coils meet the required standards for strength, durability, and other performance parameters.

- Q: What are the different types of steel coil coatings for heat resistance?

- Heat resistance is achieved through the use of different types of steel coil coatings. These coatings are designed specifically to safeguard the steel surface, preventing it from deteriorating or oxidizing under high temperatures. Organic coatings, such as epoxy, polyester, or polyurethane, are commonly used. They form a protective barrier against heat and prevent the steel from corroding or oxidizing. Organic coatings are typically employed in situations where moderate heat resistance is necessary. Another option is inorganic coatings, made from ceramic or metallic materials. These coatings offer excellent heat resistance and can endure extremely high temperatures. Industries like automotive, aerospace, and power generation frequently utilize inorganic coatings, as their components are exposed to intense heat. Specialized coatings are also available to meet specific heat resistance requirements. Silicone coatings, for instance, exhibit exceptional heat resistance and can withstand temperatures reaching 600°C (1112°F). They find common use in applications like exhaust systems, ovens, and industrial furnaces. Some steel coil coatings may also incorporate additives or fillers to enhance their heat resistance properties. These additions improve the coating's ability to withstand high temperatures and provide superior protection against heat-related issues. In conclusion, a range of steel coil coatings is available for heat resistance, including organic coatings, inorganic coatings, and specialized coatings. The choice of coating depends on the specific heat resistance requirements of the application. Factors such as temperature range, duration of exposure, and environmental conditions must be taken into account when selecting the appropriate coating.

- Q: What are the challenges in coil slitting?

- Coil slitting is a process used to cut large coils of metal into narrower strips of desired widths. While it offers several advantages in terms of efficiency and flexibility, there are also several challenges associated with coil slitting. One of the main challenges in coil slitting is ensuring consistent strip width accuracy. Since coil slitting involves cutting the metal coil into smaller strips, it is crucial to maintain consistent width measurements throughout the process. Any deviation in the strip width can lead to issues downstream in the production line, affecting the quality and functionality of the final product. This challenge requires the use of precise slitting equipment and careful monitoring of the process parameters. Another challenge in coil slitting is managing edge quality. The edge quality of the slit strips is critical, especially in applications where the edges need to be free from burrs or other imperfections. Achieving clean and smooth edges requires proper blade selection, positioning, and maintenance. Any defects or irregularities on the strip edges can impact subsequent processes like bending, welding, or coating. Additionally, coil slitting poses challenges related to the material itself. Certain types of metals, such as high-strength steels or alloys, can be more difficult to slit due to their hardness or brittleness. Slitting these materials may result in blade wear and premature failure, leading to increased downtime and maintenance costs. Furthermore, the presence of contaminants or surface defects on the coil can also affect the slitting process, requiring additional cleaning or preparation steps. Another significant challenge in coil slitting is handling and processing large coils. Coils can be heavy and unwieldy, making it crucial to have proper equipment and procedures in place to handle them safely. Additionally, the slitting process can generate significant amounts of scrap material, which needs to be efficiently managed and disposed of. Proper storage, transportation, and recycling of the scrap are essential to minimize waste and maintain a clean and organized working environment. In conclusion, coil slitting offers numerous benefits in terms of customization and productivity. However, it also presents challenges in maintaining strip width accuracy, managing edge quality, dealing with difficult materials, and handling large coils and scrap. Overcoming these challenges requires expertise, precision equipment, and careful process control to ensure the desired quality and efficiency in coil slitting operations.

- Q: What are the main factors that affect the paint adhesion on steel coils?

- The main factors that affect paint adhesion on steel coils include surface cleanliness, surface roughness, surface preparation methods, coating formulation, and application technique.

- Q: What is the market demand for steel coils?

- The market demand for steel coils is influenced by various factors such as economic growth, construction and infrastructure projects, automotive manufacturing, and consumer goods production. It fluctuates based on these industry trends and overall market conditions. Currently, the market demand for steel coils is significant due to increased construction activities, infrastructure development, and manufacturing needs globally. However, it is important to note that market demand can vary regionally and may be subject to short-term fluctuations based on specific economic and industrial factors.

- Q: How are steel coils processed for edge trimming or shearing?

- Steel coils are processed for edge trimming or shearing by first uncoiling the coil and feeding it into a machine equipped with either rotary shears or slitting knives. These tools trim or shear the edges of the coil to remove any irregularities, ensuring a precise and uniform width. The trimmed edges are then inspected for quality and smoothness before the coil is recoiled for further processing or storage.

Send your message to us

Galvanized Steel Coils SGCC, DX51D,China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords