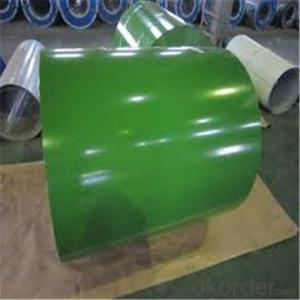

Galvanized Rolled Steel/Aluzinc Rolled Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

JIS g3141 spcc cold rolled steel coil

Grade :SPCC,SPCD,SPCE

Width:600-1500mm

WT:0.15-3mm

Product Feature

Packaging Details: Wrapped by water prove paper and plastic film, covered by steel sheet, strapped with steel strips to prevent damage from transportation

Product Specification / Models

Standard: AISI, ASTM, DIN, GB, JIS

Grade: Q195, SPCC, SPCD, SPCE, DC01-0S, St12, ST14, ST15, ST16

Thickness: 0.2mm-2.0mm

Place of Origin:China (Mainland)

Model Number: 0.2-2.0mm*600-1500mm

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: oiled

Application: Construction,mechine,building,container manufacture,shipping building,

Special Use: High-strength Steel Plate

Width: 1000mm,1200mm,1219mm,1250mm,1500mm or as per customer's request

Length: Coil or as customs' request

Carbon constructional steel: SPCC,St12,DC01,Q235A/B/C/D Constructional quality steel: 20-45#,08-15#

Carbon quality steel coil: 08AL,Z,S,P SPCD,ST14

Low carbon deep-drawing coil: SC1,SPCE,SPCEN,ST14,DCO4 Extra-deep drawing coil: SC2,ST15,DCO5,SC3,ST16,DCO6,ST17 Corrosion-resistant steel: 05CuPCrNi,09CuPCrNi,Q345GNHL

Low carbon drawing steel: SPCD,ST13,DC03

Steel Coil: COLD ROLLED

Certificate: ISO, SGS, BV

Application

1.common structural parts and parts for drawing in engineering machines

2. transportation machine construction machines, lifting machine,

3. agricultural machines, light and civil industrial, household appliance industries.

4. chemical equipments, drive casing pipe and light industrial civil industries.

Other Information

Name Cold Rolled Steel Sheet Coil

GB11253-89,Q195 Q235,IS G3141,SPCC SGCC SPCD SPCE,DIN1623,ST12 ST13 SPCD ST14, EN10130,DC01 DC02,DC03

Thickness 0.18-3.0mm

Width 680mm-2000mm or 1000/1200/1219mm/1250mm

Finish General, bright, dull and mirror finish, oiled or non-oiled

Coil ID 508mm

Coil weight 5-12 tons.

Packing as client's requirement

Certificate ISO9001:2008

Standard GB11253-89, JIS G3141,DIN1623,EN10130

- Q: What are the challenges in the production of steel coils?

- The production process of steel coils encounters several obstacles. Firstly, ensuring consistent quality throughout the process is a major challenge. It is necessary for steel coils to possess uniform thickness, width, and flatness. However, achieving this consistently can prove to be difficult due to variations in raw materials, equipment, and operating conditions. Another hurdle involves effectively managing the intense temperatures involved in the production process. Steel coils are formed by heating steel slabs or billets to extremely high temperatures and subsequently rolling them into coils. Maintaining the necessary temperatures and ensuring proper cooling can be a complex task, as any deviations can result in inconsistencies in the final product. Furthermore, the production of steel coils demands a significant amount of energy. The steel industry ranks among the largest energy consumers worldwide. The constant challenge lies in reducing energy consumption while maintaining production efficiency. To tackle this challenge, the implementation of energy-efficient technologies and process optimization is imperative. Moreover, the production of steel coils generates a substantial amount of waste and emissions. Steel manufacturing involves various chemical reactions that release pollutants such as carbon dioxide, sulfur dioxide, and particulate matter. Meeting environmental regulations and minimizing these emissions are significant challenges for the industry. Additionally, the production of steel coils often involves large quantities, necessitating efficient logistics and transportation systems. Ensuring timely delivery and minimizing damage during transportation can be challenging due to the weight and size of the coils. Lastly, the steel industry confronts market challenges, including fluctuating prices of raw materials, competition from alternative materials, and global economic conditions. Adapting to market demands and maintaining competitiveness are vital for the sustainable production of steel coils. Overall, the challenges in steel coil production encompass maintaining consistent quality, managing high temperatures, reducing energy consumption and emissions, optimizing logistics and transportation, and adapting to market dynamics. Addressing these challenges requires continuous innovation, technological advancements, and a focus on sustainability.

- Q: Where do I need hot galvanized steel coils and color coated rolls?

- In industrial or coastal areas, due to the influence of sulphur dioxide or salt in the air, the corrosion rate is accelerated and the service life is affected. In the rainy season, the coating has been soaked by rain for a long time, or the temperature is too large and easy to dew. It will be corroded quickly and the service life will be reduced. A building or building made of colored coated steel plates, often with a long service life when washed by rainwater, otherwise affected by sulfur dioxide, gas, salt, and dust. Therefore, in the design, if the roof slope is greater, the more difficult to accumulate dust and other dirt, the longer the service life; for those areas or parts that are not often washed by rain water, should be regularly washed with water.

- Q: How are steel coils inspected for damage during transportation?

- Steel coils are typically inspected for damage during transportation through visual inspections, where trained personnel carefully examine the coils for any visible signs of dents, scratches, or other forms of physical damage. Additionally, specialized equipment such as ultrasonic testing or magnetic particle inspection may be used to identify any hidden or internal defects in the coils. These inspection methods ensure that any potential damage is detected early on, allowing for prompt repairs or necessary precautions to minimize any further harm.

- Q: So, I'm looking into steel toe paddock boots. I'll be using them around horses, horses that I don't know and that are rescue horses. I'm currently looking at Equitector the Moorland paddock boots. They're $200, and I think I have to order them online. I like boots that are this style (the Moorland style)... Is there any other brand of boots that has steel toe paddock boots, that are cheaper or that I can buy in stores?

- Hi! You can hike in steel toed boots, but I wouldn't. They aren't designed for hiking, no matter what the manufacturers says. They're built to protect your feet from hazards on a job site. I bought my first pair of decent hiking boots for $10/month on layaway at an outfitters. It took forever, of course, but I didn't have the money to buy them right out. Until then, I hiked in a pair of tennis shoes. Sneakers are just fine as hiking gear, though remember that you will have no ankle support, so you need to be more careful on rocky trails. Use a pair you don't mind getting dirty and make sure they have decent ankle support. Also, this is a great time of year to buy boots if you can scrounge the money together. Most outfitters are swapping over to their spring lines and have shoe/boot sales going on. You don't have to use an outfitter, either. Lots of regular shoe or department stores sell boots that will work just fine until you can afford some nice top-line boots.

- Q: How do steel coils contribute to the manufacturing of appliances?

- Steel coils are used in the manufacturing of appliances as they serve as a primary raw material for various components such as frames, panels, and structures. These coils are processed and shaped into different forms to meet the specific requirements of different appliances. Additionally, steel coils provide durability, strength, and corrosion resistance to appliances, ensuring their long lifespan and high-quality performance.

- Q: I feel really stupid asking this question but i feel like a put metal/steel strings on my classical guitar how do you tell the difference?

- The g-string will look and feel thicker than usual, and the strings will look almost like copper.

- Q: How are steel coils unloaded from a truck or ship?

- Steel coils are typically unloaded from a truck or ship using specialized equipment such as cranes, forklifts, or coil lifters. The coils are carefully lifted off the truck or ship and then placed onto a designated area in the storage yard or warehouse using the appropriate machinery.

- Q: Hey I just got a mini 14 manufactured in 1980. I also had some .223 Wolf steel cased HP rounds (about 200) that i could shoot throught it, but I was just wondering if its a bad idea to use this steel cased ammo...? Only the casing is steel i believe... and the bullet is copper jacketedthanks for your help

- I have had significant ejection and rechambering problems with Wolf semi-auto handgun ammo. It took forever to clean the fouling that the lacquered ammo generated too. I do not know about the rifle ammo, but I won't tempt fate over cheap rounds again.

- Q: What is the process of recycling steel coils?

- The process of recycling steel coils involves several steps to ensure the maximum utilization of the material and to minimize waste. Firstly, steel coils are collected from various sources, including industrial manufacturing facilities, construction sites, and scrap yards. These coils are then transported to a recycling facility where they undergo a thorough inspection to assess their quality and determine the appropriate recycling method. Next, the steel coils are cleaned to remove any contaminants such as dirt, oil, or paint. This is typically done using chemical agents or mechanical processes, depending on the level of contamination. Cleaning the coils is crucial as it ensures the quality of the recycled steel. After cleaning, the coils are shredded or sheared into smaller pieces to facilitate further processing. This step helps to increase the surface area, making it easier to separate the steel from other materials that might be present in the coils. Once the coils are broken down into smaller pieces, they go through a process known as magnetic separation. This involves passing the steel pieces through a magnetic separator that uses powerful magnets to attract and separate the ferrous steel from non-ferrous materials like aluminum or plastic. This separation is essential as it ensures the purity of the recycled steel. The separated steel pieces are then melted in a furnace at extremely high temperatures. This melting process not only removes any remaining impurities but also allows the steel to be molded into various shapes and forms, depending on the intended application. After melting, the molten steel is poured into molds or cast into ingots to solidify. These ingots can be further processed and transformed into new steel products or used as raw material in various industries. Throughout the recycling process, the steel coils are subjected to quality control measures to ensure that the resulting recycled steel meets the required specifications and standards. This includes conducting chemical analyses and mechanical tests to verify the strength, composition, and overall quality of the recycled steel. In conclusion, the process of recycling steel coils involves collecting, cleaning, shredding, separating, melting, and molding the steel to produce new products or raw material. This process not only helps to conserve valuable resources but also reduces the environmental impact associated with traditional steel production.

- Q: I love the design! It looks great, is safe, and you can see through it just fine on camera. Do you like it?BQ: Old Blue WWF Steel Cage or the newer fence type steel cage?

- TNA steel cage is alot more better i agree with you its safe and can see through it just fine on camera.. BQ: i think newer fence type because it does slow down a match and its brutal.. Old blue cage is just a bit too wide that someone can easily jump two or three squares up and finsihed, nah its too quickly finishing a match into that cage.

Send your message to us

Galvanized Rolled Steel/Aluzinc Rolled Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords