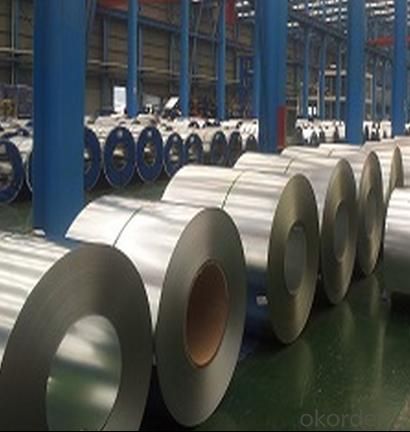

Galvanized Steel Coils/Rolled Steel Coil Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:CGCC, JIS3312

Surface Treatment:Coated

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, JIS, GB

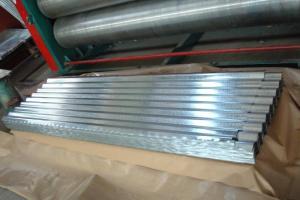

Application:Construction, Roofing and So on

Edge:Slit edge

Stock:Stock

Steel Grade:Q195-235

Thickness:0.16-0.8mm

Width:800-1250mm

Color:Ral Number

Zinc:30G/M2-100G/M2

Coils Weight:3-5tons/Coils

Export Markets:Global

Additional Info.

Packing:Export Standard Packing

Standard:JIS G3312

Origin:China

HS Code:72107000

Production Capacity:100000tons/Year

Product Description

Prepainted galvanized steel coils

1. PPGI, prepainted galvanized steel coil(Annual Output: 200, 000tons)

(1). Leading manufacturer in China

(2). Competitive price

(3). High quality

(4). Good after-sale service

2. The Feature of PPGI:

1). Geade: CGCC, other grade can be available

2). The thickness range of the PPGI: 0.16mm to 0.8mm

Tolerance of thickness of The PPGI: +/-0.03mm

3). Width range: 800mm to 1250mm

Tolerance of width: +/-3.00mm (aiming to +/-2.00mm)

4). Zinc coating: Z40-Z275

5). Coil internal diameter: 508mm

6). Packing: Standard waterproof paper and galvanized steel protection cover and steel strip packed

7). Applications of PPGI: Widely used for roofs, outer walls, ovens, Explosive-proof steel, electrically controlled cabinets, and industrial freezers in the Residential and industrial buildings

- Q: What are the common methods of packaging steel coils for transportation?

- The common methods of packaging steel coils for transportation include strapping, wrapping, and using wooden or steel cradles. Strapping involves securing the coils with metal or polyester bands, while wrapping involves using stretch film or shrink wrap to protect the coils from moisture and damage. Wooden or steel cradles are used to stack and secure multiple coils together, ensuring stability during transportation.

- Q: Nickel is ferro magnetic in nature. But when it is added with stainless steel, it makes stainless steel non-magnetic. What is the structural changes happened with the presence of nickel?

- Steel is magnetic because of the alignment of the spin in the electrons of the atoms in the crystaline matrix of the steel. Nickel atoms are not the same size as Iron atoms and Chromium atoms. by having several different sizes of atoms in the alloy, it prevents a uniform crystaline matrix from being formed. If you imagine a box of marbles that are all the same size, they will all settle into a regular pattern in the box. But a bunch of mismatched marbles will be jumbled together in irregular patterns. This prevents the magnetic properties of either element from asserting itself.

- Q: I am in the market for a good hunting knife under $100. I am primarily looking for a knife that will keep it's edge. What type of steel should I be looking for?

- Don't know much about steels, but apparently SV30 is the toughest son of ore you can look for, and it's so tough I've heard of knife makers rejecting it for softer steel. Look for Gerber and Buck for low end SV30 knives under $100.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: What are the different coil slitting methods used for steel coils?

- There are several coil slitting methods commonly used for steel coils. These methods are employed to cut larger steel coils into smaller, narrower coils that are suitable for specific applications. 1. Blade Slitting: This is the most common method used for coil slitting. It involves using circular knives or blades to cut the steel coil into narrower strips. The blades are set at predetermined distances and are usually mounted on a rotating shaft. The coil is passed through the blades, and the circular motion of the blades slices through the coil, creating the desired narrower strips. 2. Rotary Shear Slitting: In this method, two sets of rotary shear knives are used to cut the steel coil. The upper and lower sets of knives rotate in opposite directions, creating a scissor-like cutting action. The coil is passed through the shearing blades, and the sharp edges of the knives slice through the coil, producing the desired narrower strips. 3. Sliding Shear Slitting: Sliding shear slitting is another method used for coil slitting. In this method, a stationary upper knife and a moving lower knife are used to cut the coil. The lower knife moves back and forth across the coil, while the upper knife remains stationary. The coil is passed through the moving knife, which cuts it into narrower strips. 4. Crush Slitting: Crush slitting is a less common method used for coil slitting. In this method, the steel coil is passed through a set of rollers equipped with blades. The blades are not sharp, but the pressure exerted by the rollers crushes and fractures the coil, creating the desired narrower strips. 5. Laser Slitting: Laser slitting is a modern and precise method used for coil slitting. It involves using a laser beam to cut through the steel coil. The laser beam is directed onto the coil, and its high intensity melts and vaporizes the steel, creating a narrow slit. Laser slitting offers high accuracy and a clean cut, making it suitable for specialized applications. Each of these coil slitting methods has its advantages and limitations, and the choice of method depends on factors such as the type of steel, desired strip width, production volume, and required precision. Manufacturers select the most appropriate method based on their specific requirements and the properties of the steel coils they are processing.

- Q: What is the average turnaround time for processing steel coils?

- The average turnaround time for processing steel coils can vary depending on several factors such as the size and complexity of the coils, the specific processing requirements, and the efficiency of the manufacturing facility. However, in general, the average turnaround time for processing steel coils can range from a few days to a couple of weeks.

- Q: engineering sloutions related to steel fabrication

- not okorder /

- Q: What are the common methods of slitting or shearing steel coils?

- The common methods of slitting or shearing steel coils include: 1. Rotary Shearing: This method involves using a rotary shear machine that uses a set of rotating blades to cut through the steel coil. The blades move in a circular motion, slicing through the coil to create individual strips of the desired width. 2. Scissor Shearing: Scissor shearing is another common method of cutting steel coils. It involves using a pair of scissor-like blades to make the cuts. The blades are typically operated by hydraulic or mechanical systems, and they cut through the coil by exerting pressure on the material. 3. Slitting: Slitting is a popular method used to cut steel coils into narrower strips. It involves passing the coil through a set of circular blades, known as slitters, which are set at specific distances apart. The slitters cut through the coil, creating multiple narrower strips of the desired width. 4. Guillotine Shearing: Guillotine shearing is a method that uses a large, powerful guillotine machine to cut through the steel coil. The machine features a long blade that moves vertically to shear the coil. This method is often used for thicker steel coils and can produce clean, straight cuts. 5. Laser Cutting: Laser cutting is a more advanced method that uses a high-powered laser beam to cut through steel coils. The laser beam is directed by computer-controlled systems, allowing for precise and accurate cutting. Laser cutting is often used for complex shapes or when high precision is required. Each of these methods has its advantages and is suitable for different applications. Factors such as the thickness of the steel coil, desired strip width, and the level of precision required will determine the most appropriate method to use.

- Q: I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon steels are mentioned in the debates, but they aren't very sophisticated in their design. Now the higher end of this middle class of katana ($250-$1000) uses higher carbon. spring, damascus, and other various steels and combinations. I've heard a lot about the strength of damascus steel and it's cutting power. But I look for more than that. I've also been looking at (and for) durability, flexibility, and how well it stands up to contact. So I guess what I'm asking is for the opinion of people who have used these steels, and an answer on what the community thinks is the best steel for a mid range ($250-$1000) battle-ready katana. Looking forward to some good answers.

- There is no such thing as a battle ready katana... if it is not ready for battle - it is not a katana. Having said that: The hardness of the cutting edge depends on the carbon content the better (in general). 1045 is poor quality steel for sword manufacture. Musashi swords are cheap pieces of crap. 1060 is better. Some manufacturers use modern materials that aren't perhaps consistent with traditional manufacture, like 9260 silicon spring steel or even L6 Bainite. Damascus steel is not a type of steel at all. It is a folding technique that creates a wavy grain in the metal. It may or may not mean that a sword is good. No swords will stand up to contact with other swords. They will inevitably be damaged. The best way to find a quality sword is to ask you instructor. There are no quality swords under a thousand dollars. The answer also depends on what you are going to do with the sword. It may also depend on the style or school of swordsmanship.

- Q: I have taylormade burner steel irons and I was wondering what would the flex of steel be if you were to compare it to graphite shafts, like regular, stiff, super stiff, etc...THANKS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- If i understand you correctly, i think you misunderstand shafts. Steel shafts vs. graphite shafts these days is more of a competition of weights, not flexibility. Both steel and Graphite have different flex profiles available from Ladies (L) to super stiff (X). Graphite may feel a little more whippy than steel because of the lighter weight. Shafts will vary by company as well. Stiff from True temper may not be as stiff as one from Aldila, or vice verse. You can also make a shaft play stiffer or more flexible by where you cut the length. This is called tipping. Take more from the bottom and it will be stiffer, more from the grip end and it will play more flexible.

Send your message to us

Galvanized Steel Coils/Rolled Steel Coil Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords