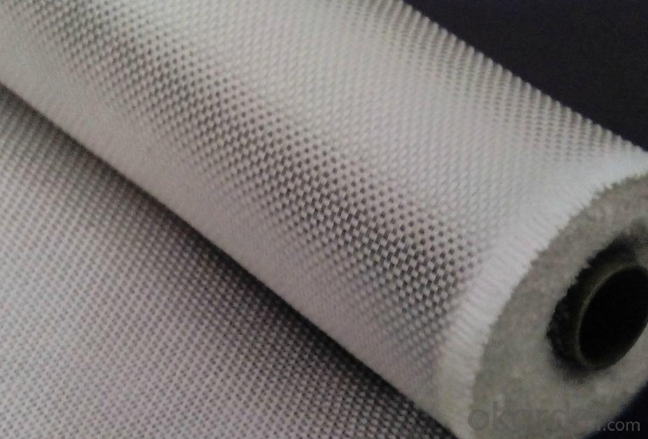

Fiberglass Roving - C-Glass Fiber Woven Roving for FRP Products - 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Properties of E-Glass Fiber Woven Roving

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handing easy

Good moldability, fast and complete wet in resins, resulting in high productivity

Good transparency and high strength of composite products

Glass fiber woven rovings are bidirectional fabric made by interweaving direct rovings and compatible with many resin like UP, vinyl ester, epoxy and phenolic resin.

It is a high-performance reinforcement widely used in hand lay-up and robot processes for the production of boats, vessels, plane and automotive parts, furniture and sports facilities

Package of E-Glass Fiber Woven Roving

Woven roving are wounded onto a paper tube which has an inside diameter of 89mm, and the roll has a diameter of 260mm. The roll is wrapped up with plastic film, and then packed in a cardboard box or wrapped up with kraft paper. The rolls are to be horizontally placed. For transporation the rolls can be loaded into a container directly or on pallets.

Storage of E-Glass Fiber Woven Roving

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respectively

Woven roving Specification:

| Product code | Mass(g/m²) | Fabric density(end/cm) | Width (mm) | Roll weight(kg) | Compatible resins | |

| warp | weft | |||||

| EWR400 | 400 | 3.6 | 3.2 | 1500 | 40 | UP/EP/VE |

| EWR400 | 400 | 3.6 | 3.2 | 1500 | 50 | UP/EP/VE |

| EWR600 | 600 | 2.6 | 2.4 | 1500 | 40 | UP/EP/VE |

| EWR600 | 600 | 2.6 | 2.4 | 1500 | 50 | UP/EP/VE |

| EWR800 | 800 | 1.8 | 1.5 | 1500 | 40 | UP/EP/VE |

| EWR800 | 800 | 1.8 | 1.5 | 1500 | 50 | UP/EP/VE |

IMAGES:

FAQ of Chopped strand mat

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

1 *40HQ each day.

- Q: Can glass fiber be used for cement components

- Glass fiber reinforced cement products uses glass?fiber to produce cement component. The glass fiber should be alkali resistant glass fiber twist roving, alkali resistant glass fiber chopped strand and alkali resistant glass fiber mesh cloth which comply with JC/T5,72 or JC/T 841 requirements. The cement should be in accordance with JC7/14 and portland cement should comply with the provisions of GB 175. Portland cement must be mixed with absorable Ca (O H), alkali materials or acrylic?acid emulsion with the content of alkali resistant glass fiber is higher than 16%.

- Q: Materials of european component

- Polymer:.5%, the low alkalinity sulphoaluminate cement, forming perfectly, do not use additives which contain calcium chloride based. 2. It is anti-permeability. As the Portland cement, it can be formed at one time. 4, China requires that when using the ordinary portland cement, the zirconia's content do not less than 16, including alkali resistant glass fiber roving, white portland cement..5%:. 3. plasticizer: The fibers used in GRC must be alkali resistant glass fiber, fiber, early strength agent, alkali resistant glass fiber mesh and retarder. As the requirement of Europe and America, the content of zirconium oxide in glass fiber should be no less than 16: The acrylic emulsion is usually the polymer: We can add some of the volcanic ash active material selectively, that is, acrylic copolymerized emulsion. 5: We can select soft rubber mold, made by high temperature resin which suit the hard outer mold: High efficiency water and anti freezing agents reducing agent can be selectively added. That is conducive to comprehensive performance, enhance the durability of GRC products commonly. The cement can be hardening at fast speed. Sulphoaluminate cement /additives, alkali resistant glass fiber chopped yarn is easy demoulding.

- Q: grc fiberglass

- the content of ZrO2 in alkali resistant glass fibre whcih was used as reinforced material for portland cement is not less than 16. According to specific provisions in the T841, it is clearly required that alkali-resistant glass fiber must be used in GRC with its type incledes twistless roving.

- Q: What are the causes and methods of glass fiber surface treatment?

- Transfer process: the incorporation of surface treating agents into resins (mainly for wrapping and moulding).

- Q: How to produce glass steel?

- Material: Glass cloth, resin, curing agent tool: Glass?pane or polyester i thin?film process: According to the specifications for glass?reinforced?plastics, glass plane or polyester i thin film should be prepared and then you should tail glass cloth in accordance with requirements. At first, you should compound resin, and then you should put cloth that already have been tailed on the glass pane and cover it with compounded resin until its thickness meets requirements after removing all bubbles in it. After that, you should continue to cover it with polyester i thin film without bubbles and put a piece of glass on it if you want it more neat. A new product is ready after taking off the glass fiber reinforced plastics and trimming it carefully.

- Q: Medium alkali glass fiber cloth

- It is mainly used for large and medium sized non-metal container, equipment, pipe and shell.

- Q: Carbon fiber is better than glass fiber reinforced plastic

- Carbon fiber is better than glass fiber reinforced plastics, lighter in weight, stronger in strength and stronger in toughness. Compared with the traditional carbon fiber glass fiber, the young's modulus is more than 3 times; compared with Kevlar fiber, the young's modulus is about 2 times in the organic solvent, acid and alkali insoluble swelling, outstanding corrosion resistance.

- Q: Is arbon fiber better than glass fiber reinforced plastic

- Lighter and more toughness.

- Q: What does glass fiber used for?

- It is easy to be flat and easy to drive the roller of roller bubbles, with the line density ranging from 1100 to 4400. The fabric, made by very fine fiber,can be divided into several types. E- glass is also known as alkali free glass. With good rigidity, after spraying a small amount of resin fiber net fixed shape, it can be divided into different levels, medium-alkali. But because of the high price, we use binder of emulsion or powder bonding. After heating and solidating, it becomes chopped strand felt. (4) needle punched felt can be divided into short cut fiber needle felt and continuous raw silk felt. Along the width of the direction, the area and quality is uniform. (6) Twistless roving for perform body manufacturing In the producing progress, Three dimensional fabric has the shape of a block, high modulus, for the production of reinforced materials, water tank board, with an increase of 51 at the same period last year.

Send your message to us

Fiberglass Roving - C-Glass Fiber Woven Roving for FRP Products - 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords