Fiberglass Fabrics Reinforced Fiberglass Roofing Panels (Sheets) for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Roofing Panels(Sheets) for Constructin Using

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. The intensity and stiffness is quite prominent,.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. Corrosion resistance no rust, no maintenance, long service life.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

- High strength.

Easy to maintain.

Long service life.

Easy to install.

Good light transmittance.

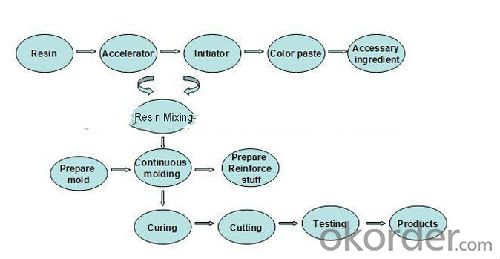

Production Process

Specification&Technical Parameters

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: Would you like to let us get your sampels?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can fiberglass fabric be used for ducting?

- Yes, fiberglass fabric can be used for ducting. Fiberglass is a lightweight and flexible material that has excellent insulation properties. It is often used in the construction of air ducts to help maintain the temperature and airflow of the system. Fiberglass fabric can be wrapped around the ducts or used as lining to provide thermal insulation and prevent heat transfer. Additionally, fiberglass is resistant to moisture, mold, and mildew, making it a suitable choice for ducting in humid environments. However, it is important to note that fiberglass fabric should be properly installed and sealed to ensure proper air quality and prevent any loose fibers from entering the duct system.

- Q: Can fiberglass fabric be used for making tarpaulins?

- Tarpaulins can indeed be made using fiberglass fabric, which is renowned for its durability, strength, and ability to withstand harsh weather conditions. This versatile material finds widespread use in several applications, including tarpaulin production. Despite its lightweight nature, fiberglass fabric boasts exceptional tear resistance and can endure high temperatures. Moreover, its waterproof properties make it a perfect choice for safeguarding goods and equipment from rain, snow, and other environmental elements. In addition, fiberglass fabric's resistance to chemicals, UV rays, and mildew contributes to its longevity and enhances its performance as an ideal tarpaulin material.

- Q: Is fiberglass fabric resistant to bacteria and fungi?

- In general, bacteria and fungi find it difficult to thrive on fiberglass fabric due to its non-porous nature. Moreover, fiberglass fabric is commonly enriched with special coatings or finishes, which further boost its ability to ward off these microorganisms. Consequently, fiberglass fabric emerges as an optimal selection for scenarios that prioritize cleanliness, such as the medical or food processing sectors. Nonetheless, it is crucial to acknowledge that the level of resistance may differ based on the particular type of fiberglass fabric and the existence of supplementary treatments or coatings.

- Q: Can fiberglass fabric be used for making welding curtains?

- Indeed, fiberglass fabric possesses the capability to be utilized in the creation of welding curtains. Renowned for its exceptional heat resistance traits, fiberglass fabric emerges as a fitting substance for safeguarding against the emergence of sparks and flames that welding activities generate. Notably, it endures elevated temperatures and impedes the propagation of fire, thereby establishing itself as a secure and efficacious preference for welding curtains. Furthermore, the durability and commendable tear resistance of fiberglass fabric ensure its capacity to endure the arduous conditions inherent in a welding setting.

- Q: What are the different weights or thicknesses available for fiberglass fabrics?

- There are various weights or thicknesses available for fiberglass fabrics, ranging from lightweight options like 3 oz per square yard to heavier options like 18 oz per square yard.

- Q: Are fiberglass fabrics resistant to mildew or fungus?

- Fiberglass fabrics have a tendency to resist mildew or fungus in most cases. This is because fiberglass, being a non-porous material, does not create an ideal environment for the growth of mold, mildew, or fungus. Furthermore, special coatings or finishes are frequently applied to fiberglass fabrics to further enhance their resistance against these types of organisms. However, it is worth noting that although fiberglass fabrics generally repel mildew or fungus, they are not entirely immune. In instances where the fabric is excessively exposed to moisture or not adequately maintained, there is still a possibility for mildew or fungus to develop. Hence, it is advisable to adhere to proper cleaning and maintenance protocols when dealing with fiberglass fabrics to guarantee their durability and prevent any potential growth of mold or mildew.

- Q: Can fiberglass fabrics be used for insulation in industrial boilers?

- Yes, fiberglass fabrics can be used for insulation in industrial boilers. Fiberglass is a popular choice for insulation in various applications due to its excellent thermal resistance properties. It is a lightweight and flexible material that can effectively trap heat and prevent its transfer to the surrounding environment. In industrial boilers, fiberglass fabrics can be used as insulating jackets or covers to retain heat within the system, thereby improving energy efficiency and reducing heat loss. Additionally, fiberglass is non-combustible, which makes it a safe option for insulation in high-temperature environments such as industrial boilers.

- Q: How does fiberglass fabric perform in water repellency?

- Fiberglass fabric exhibits exceptional water repellency due to its composition of woven glass fibers, which possess a natural hydrophobic quality. This inherent characteristic prevents water molecules from easily permeating the fabric, resulting in a high level of resistance to water absorption. The hydrophobic nature of fiberglass fabric makes it an ideal choice for applications where water repellency is essential, such as the manufacturing of outdoor apparel, tents, and boat covers. Even when exposed to water, the fabric remains relatively dry, avoiding any increase in weight or water saturation. Furthermore, the construction of fiberglass fabric enables it to maintain its water repellency over an extended period. The fabric does not readily lose its hydrophobic properties, even with repeated exposure to water or washing. This durability makes fiberglass fabric a reliable option for situations requiring long-term water resistance. It is worth noting, however, that while fiberglass fabric exhibits a high resistance to water absorption, it is not entirely waterproof. Under extreme circumstances like heavy rainfall or prolonged submersion, some water may eventually seep through the fabric. Nevertheless, fiberglass fabric surpasses many other materials in terms of water repellency, making it a favored choice across various industries.

- Q: What are the different fiberglass fabric coatings for weather resistance?

- Some different fiberglass fabric coatings for weather resistance include silicone coatings, polyurethane coatings, acrylic coatings, and vinyl coatings. These coatings help to provide protection against moisture, UV rays, and other environmental elements, enhancing the durability and longevity of fiberglass fabric in various weather conditions.

- Q: How do fiberglass fabrics perform in terms of UV resistance?

- Fiberglass fabrics have excellent UV resistance properties. The composition of fiberglass, which is made from fine fibers of glass, allows it to withstand prolonged exposure to ultraviolet (UV) radiation without significant degradation. Unlike many other fabrics, fiberglass does not easily deteriorate or become brittle when exposed to sunlight. The glass fibers in fiberglass fabrics are inherently resistant to UV rays due to their inorganic nature. This means that they do not contain any organic compounds that can be broken down or degraded by UV radiation. As a result, fiberglass fabrics can maintain their strength and integrity even after prolonged exposure to sunlight. In addition to their natural UV resistance, fiberglass fabrics can be further enhanced by the addition of special coatings or treatments. These coatings can provide additional protection against UV rays, increasing the fabric's longevity and ability to withstand outdoor conditions. Overall, fiberglass fabrics are known for their exceptional UV resistance. They are commonly used in applications where exposure to sunlight is a concern, such as outdoor furniture, marine applications, and automotive components. Their ability to withstand UV radiation makes them a durable and reliable choice for various industries and environments.

Send your message to us

Fiberglass Fabrics Reinforced Fiberglass Roofing Panels (Sheets) for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords