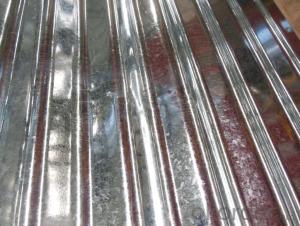

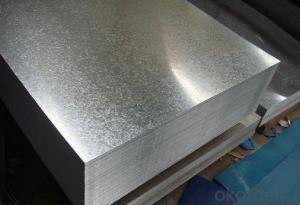

FDHOT-DIP GALVANIZED STEEL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HOT-DIP GALVANIZED STEEL 72104910

THICKNESS:0.18mm-1.5mm

WIDTH:900mm-1250mm

COATING MASS:Z30-Z275

SPANGLE:Regular Spangle,Minimized Spangle,Zero Spangle

SURFACE TREATMENT:N0on or Chromated,Non or Oiled,Non or Anti Finger Print

COIL INNER DIAMETER:508mm/610mm

COIL WEIGHT:3mt-7mt

In continuous units in cold rolled steel strip, galvanized steel (electro galvanized and hot dip galvanized) as substrate, after surface pretreatment (degreasing and science processing), using the method of roll coating, coated with a layer or multi-layer liquid coating of plate, after baking and cooling income is the coating steel plate. Because the coating can have a variety of colors, on the habits of the coated steel sheet is called color coating steel plate. Because the coating is carried out before the sheet metal forming, in foreign countries which is called pre coating plate.

Color coated steel sheet is an organic coating coating on the steel surface, it has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, easy processing molding, but also allows the user to reduce costs, reduce pollution.

From the United States in 1935 to establish the first continuously coated steel line to begin, color coated steel plate has been widely applied, the current color coated plate varieties, about more than 600 kinds, the advantages of color coated sheet and organic polymer and steel plate of the two, which has good colorability, organic polymer molding, corrosion resistance and decorative, and steel plate with high strength and easy processing, can easily be punching cutting, bending, deep drawing processing. Made this makes organic coated steel sheet products have excellent practical, decorative, workability, durability.

- Q: Are steel sheets suitable for high-temperature applications?

- Yes, steel sheets are suitable for high-temperature applications due to their excellent thermal resistance and strength. Steel can withstand elevated temperatures without significant deformation or loss of strength, making it an ideal material for various industries such as automotive, aerospace, and manufacturing. Additionally, steel sheets can be further enhanced with heat-resistant coatings or alloys to enhance their performance in extreme heat conditions.

- Q: What are the different sheet metal finishing techniques for steel sheets?

- Some of the different sheet metal finishing techniques for steel sheets include deburring, grinding, polishing, sanding, and painting.

- Q: Can steel sheets be used for insulation purposes?

- No, steel sheets cannot be used for insulation purposes as they conduct heat and electricity, rather than providing insulation against them.

- Q: Are steel sheets suitable for automotive body panels?

- Yes, steel sheets are suitable for automotive body panels. They provide excellent strength, durability, and crash-resistance, making them a popular choice in the automotive industry. Additionally, steel sheets are cost-effective and easily customizable, making them an ideal material for automotive body panels.

- Q: What are the safety precautions when handling steel sheets?

- When handling steel sheets, some important safety precautions include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed shoes to protect against cuts and injuries. It is necessary to lift and carry steel sheets properly using correct lifting techniques and equipment to avoid strain or back injuries. Additionally, ensuring a clean and organized work area, free from any tripping hazards, is essential. Proper storage and stacking of steel sheets is crucial to prevent them from falling or shifting, causing accidents. Regular inspection and maintenance of equipment used for handling steel sheets is also important to ensure safe operation.

- Q: Do the steel sheets have any sharp edges?

- Yes, steel sheets can have sharp edges. During the manufacturing process, steel sheets are often cut or sheared, which can leave sharp edges. It is important to handle steel sheets with caution and use appropriate protective equipment, such as gloves, when working with them to avoid any injuries from the sharp edges.

- Q: How do you clean and maintain steel sheets?

- To clean and maintain steel sheets, start by wiping them down with a damp cloth to remove any surface dirt or debris. For tougher stains, you can use a mild detergent or stainless steel cleaner, applied with a soft cloth or sponge. Always rinse the sheets thoroughly and dry them completely to prevent water spots or corrosion. To maintain the steel's shine, you can periodically apply a stainless steel polish or oil to protect against rust and enhance its appearance.

- Q: What is the thickness of the water resisting steel plate of the electrical outlet?

- Water blocking plate is made of stainless steel plate overall customization, visibility and strong practicability, top post reflective strips into professional production engineering grade reflective film, reflective film with gummed paper durable.

- Q: Can steel sheets be used for elevator interiors?

- Yes, steel sheets can be used for elevator interiors. Steel is a durable and versatile material that can withstand high levels of traffic and wear. It can be easily customized, painted, or textured to create an aesthetically pleasing interior design for elevators. Additionally, steel sheets offer excellent resistance to fire and moisture, making them a suitable choice for elevator interiors.

- Q: How do steel sheets handle electromagnetic interference?

- Steel sheets are highly effective in handling electromagnetic interference (EMI) due to their inherent electrical conductivity and magnetic permeability. These properties allow steel sheets to act as a shield against electromagnetic waves and prevent their penetration into or out of an enclosed space. When exposed to EMI, steel sheets act as a barrier, reflecting and absorbing electromagnetic waves, thus minimizing their impact on electronic devices and systems. This shielding effect is particularly crucial in sensitive environments such as data centers, laboratories, or industrial facilities where electromagnetic interference can disrupt electronic equipment and compromise their functionality. The thickness and composition of the steel sheet also play a significant role in determining its effectiveness in handling EMI. Thicker sheets provide better shielding due to increased attenuation of electromagnetic waves. Additionally, certain types of steel alloys, such as carbon steel or stainless steel, offer enhanced EMI shielding capabilities. It is important to note that while steel sheets provide excellent EMI shielding, they are not entirely impervious to electromagnetic waves. Factors such as the frequency of the waves and the size of any openings or gaps in the steel sheet can affect their shielding effectiveness. Therefore, proper installation and grounding techniques are essential to ensure optimal EMI protection. Overall, steel sheets are a reliable choice for managing electromagnetic interference, making them a preferred material in various industries where EMI shielding is critical for the uninterrupted operation of electronic devices and systems.

Send your message to us

FDHOT-DIP GALVANIZED STEEL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords