Hot-Dip Galvanized Steel Sheet in Competitive Price and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

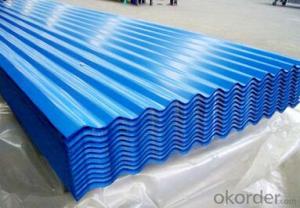

Hot-dip Zinc Coating Steel Building Roof Walls

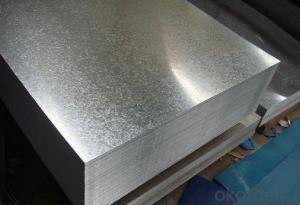

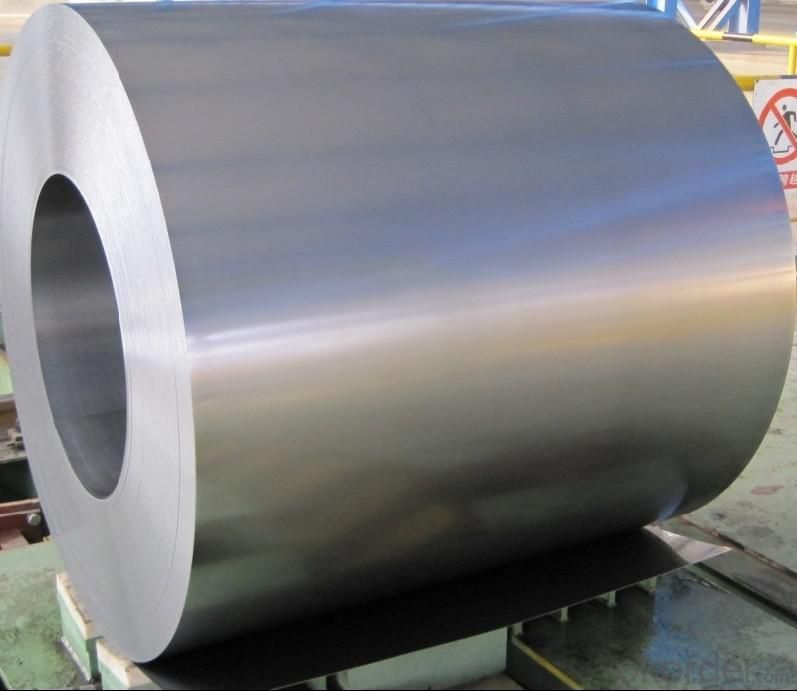

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the difference between a self-color and painted steel sheet?

- A self-color steel sheet is one that has not undergone any additional surface treatment or coating, whereas a painted steel sheet has been coated with a layer of paint or another protective coating to enhance its appearance and provide added protection against corrosion or other environmental factors.

- Q: Are steel sheets suitable for outdoor applications?

- Yes, steel sheets are suitable for outdoor applications. Steel is highly durable, weather-resistant, and can withstand harsh environmental conditions, making it an excellent choice for outdoor usage.

- Q: Do the steel sheets have any sharp edges?

- Yes, steel sheets can have sharp edges. During the manufacturing process, steel sheets are often cut or sheared, which can leave sharp edges. It is important to handle steel sheets with caution and use appropriate protective equipment, such as gloves, when working with them to avoid any injuries from the sharp edges.

- Q: What are the common sizes of steel sheets available?

- To meet the diverse needs of different industries and applications, a variety of sizes of steel sheets are available. The sizes of steel sheets can vary depending on the manufacturer and the specific requirements of the customer. However, there are standard sizes widely available in the market. The most popular sizes of steel sheets are as follows: 1. 4 feet by 8 feet: This size is widely used in construction, manufacturing, and automotive industries. It is suitable for various applications like roofing, siding, and fabrication due to its large surface area. 2. 4 feet by 10 feet: Similar to the 4 feet by 8 feet sheets, this size provides a larger surface area. It is ideal for bigger projects that require more material. 3. 5 feet by 10 feet: With an even larger surface area than the 4 feet by 10 feet sheets, this size is perfect for industrial applications that need extensive coverage. 4. 6 feet by 12 feet: This larger size is commonly used in heavy-duty applications such as shipbuilding, construction of large structures, and industrial machinery. It's important to acknowledge that these are just some of the common sizes available. Manufacturers offer many other sizes to meet specific requirements. Moreover, steel sheets can be custom-cut to fit specific dimensions, allowing for greater flexibility and tailoring to individual project needs.

- Q: Can steel sheets be recycled multiple times?

- Yes, steel sheets can be recycled multiple times without losing their properties or quality. Steel is a highly recyclable material that can be melted down and reused repeatedly, making it an environmentally sustainable choice.

- Q: Can steel sheets be used for manufacturing storage racks or shelves?

- Yes, steel sheets can be used for manufacturing storage racks or shelves. Steel is a durable and strong material that can withstand heavy loads, making it suitable for constructing storage racks or shelves that need to support various items. Additionally, steel sheets can be easily shaped and customized to accommodate different sizes and designs, making them highly versatile for manufacturing storage solutions.

- Q: Are steel sheets suitable for outdoor sculptures or artwork?

- Yes, steel sheets are suitable for outdoor sculptures or artwork. Steel is a durable and weather-resistant material that can withstand various environmental conditions, making it ideal for outdoor installations. Additionally, steel sheets offer versatility in terms of shape, form, and texture, allowing artists to create unique and long-lasting outdoor sculptures or artwork.

- Q: Are steel sheets suitable for elevator doors?

- Yes, steel sheets are suitable for elevator doors. Steel is a strong and durable material that provides security and safety for elevator systems. It can withstand the constant opening and closing of elevator doors and offers protection against external factors. Additionally, steel sheets can be customized and designed to enhance the aesthetic appeal of elevator entrances.

- Q: Are the steel sheets suitable for architectural applications?

- Yes, steel sheets are suitable for architectural applications due to their durability, strength, and versatility in various construction projects such as roofing, cladding, and structural frameworks.

- Q: Can steel sheets be used for containers or storage units?

- Yes, steel sheets can be used for containers or storage units. Steel is a durable and strong material that provides excellent protection for storing goods or as containers for transportation. Additionally, steel is resistant to corrosion, making it suitable for long-term storage in various environments.

Send your message to us

Hot-Dip Galvanized Steel Sheet in Competitive Price and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords