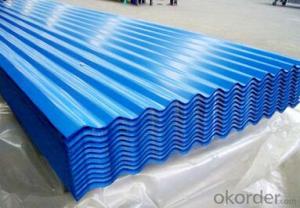

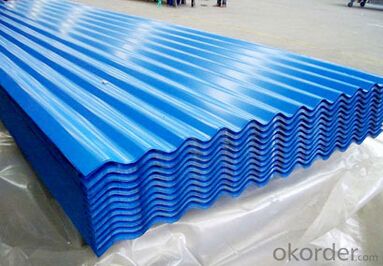

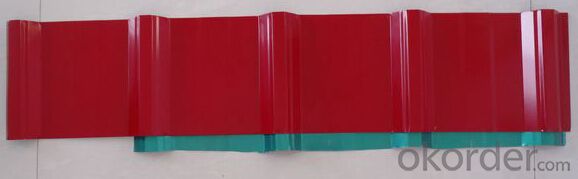

Best COATED GALVANIZED CORRUGATED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

raw materials | SGCC |

thickness | 0.12-3.2mm |

width | 100-1500mm |

length | 500-12000mm |

model | CGCC,DX51D+Z,DX52D+Z,DX53D+Z,DX54D+Z,etc. |

use | roof structure,surface sheet of balcony,etc. |

surface paint | EP,PE,HDP,SMP,PVDF |

coating process | double coating double baking |

coating | high-grade polyester(PE) lacquer |

painting thickness | top side:12-25 microns,bottom side:5-10 microns |

zinc coating | 40-275g/m2 or as request |

PACKAGE: FULL WRAPPED ANTI-DAMP PAPER INSIDE, AND STEEL SHEET OUTSIDE IN 20'FCL.

SHIPMENT:WITHIN 30 DAYS AFTER RECEIPT OF ADVANCED PAYMENT

DOCUMENTS REQUIRED: 1,FULL SET(3/3) OF ORIGINAL CLEAN ON BOARD BILL OF LADING;2,ORIGINAL SIGNED COMMERCIAL INVOICE, IN 3 ORIGINALS AND 3 COPIES;3,ORIGINAL PACKING LIST IN 3 ORIGINALS AND 3 COPIES;

TERMS OF PAYMENT:30% ADVANCED PAYMENT BEFORE PRODUCTION,BALANCE BEFORE SHIPMENT

- Q: What is the difference between a black and pickled steel sheet?

- A black steel sheet refers to a plain carbon steel sheet that has not undergone any additional surface treatment. It has a characteristic dark appearance due to the presence of an iron oxide scale on its surface. On the other hand, a pickled steel sheet has undergone a surface treatment process called pickling, which involves removing the oxide scale using an acid solution. This treatment results in a clean and smooth surface, making it more suitable for further processing or application.

- Q: How are steel sheets protected during cutting and fabrication?

- To ensure the quality and prevent damage, various methods are employed to protect steel sheets during cutting and fabrication. One widely used approach is galvanizing, which entails applying a zinc coating to the surface of the steel sheet. This zinc coating acts as a barrier against corrosion and other forms of harm, making it particularly effective in outdoor settings where steel sheets are exposed to moisture and harsh elements. Another technique for safeguarding steel sheets during cutting and fabrication involves the use of lubricants or coolants. These substances are applied to both the cutting tools and the steel sheet itself to reduce friction and minimize heat generation. By doing so, lubricants and coolants help prevent warping and distortion of the steel sheet during the cutting and fabrication process. Moreover, protective films or tapes are often utilized during the fabrication of steel sheets. These films or tapes shield the sheets from scratches, abrasions, and other physical damage that may occur during handling or transportation. In addition to these methods, proper handling and storage practices play a crucial role in protecting steel sheets during cutting and fabrication. It is essential to store the sheets in a controlled environment to prevent exposure to damaging elements such as moisture and extreme temperatures. Additionally, they should be handled with care to avoid impacts or bending that could compromise their structural integrity. In summary, steel sheets are protected during cutting and fabrication through the combined use of surface coatings, lubricants or coolants, protective films or tapes, and proper handling and storage practices. These measures ensure the quality and durability of the sheets, allowing them to maintain their integrity throughout the fabrication process and beyond.

- Q: What are the different methods of surface preparation for steel sheets?

- There are several methods of surface preparation for steel sheets, including abrasive blasting, chemical cleaning, mechanical cleaning, and pickling. Abrasive blasting involves using high-pressure air or water with abrasive materials to remove rust, scale, and contaminants from the surface. Chemical cleaning uses chemicals to dissolve or loosen contaminants, while mechanical cleaning involves using wire brushes, sanding, or grinding to physically remove dirt and rust. Pickling is a process of immersing the steel sheets in an acid solution to remove oxide scale and other impurities. Each method has its own advantages and is chosen based on the specific requirements and conditions of the steel sheet application.

- Q: Are steel sheets magnetic?

- Yes, steel sheets are magnetic.

- Q: What are the common thicknesses for galvanized steel sheets?

- The common thicknesses for galvanized steel sheets range from 0.4mm to 3mm, with the most commonly used thicknesses being 0.8mm, 1mm, and 1.2mm.

- Q: How are steel sheets inspected for defects?

- Steel sheets are typically inspected for defects using various techniques such as visual inspection, non-destructive testing methods like ultrasonic testing, magnetic particle inspection, and eddy current testing. These methods help identify any surface or internal defects such as cracks, voids, or abnormalities that may affect the quality and performance of the steel sheets.

- Q: What is the thickness tolerance for steel sheets?

- The thickness tolerance for steel sheets can vary depending on the specific grade of steel and the manufacturing process. In general, the industry standard for steel sheet thickness tolerance is typically ±0.005 inches (0.13 mm). However, it is important to note that different applications and industries may have their own specific tolerance requirements. Therefore, it is essential to consult the relevant standards and specifications for the specific steel sheet being used to determine the appropriate thickness tolerance. Additionally, some manufacturers may offer tighter tolerances based on customer requirements or specialized applications.

- Q: What is the maximum size of the steel sheets available?

- The specific supplier or manufacturer determines the maximum size of available steel sheets, which can vary. Generally, steel sheets come in a variety of sizes, ranging from 36 inches to 72 inches in width, and 96 inches to 240 inches in length. However, it should be noted that these dimensions may differ depending on the supplier's capabilities and the customer's specific requirements. Therefore, it is recommended to directly contact a supplier or manufacturer for information regarding the largest size of steel sheets they can offer.

- Q: What are the fire resistance properties of steel sheets?

- Steel sheets have excellent fire resistance properties. Due to their high melting point and low thermal conductivity, steel sheets can withstand high temperatures for an extended period of time without losing their structural integrity. This makes them a reliable choice for construction materials in fire-prone areas, as they can help contain and prevent the spread of fire.

- Q: Are the steel sheets coated with any protective material?

- Indeed, a protective material is applied to the steel sheets, ensuring their durability and resistance against corrosion. Typically, this coating is added to the steel sheets to enhance their strength and safeguard them from external elements such as moisture, chemicals, and adverse weather conditions. It acts as a formidable shield, preventing the steel from rusting or deteriorating. The specific protective material used may vary depending on the intended purpose and specific requirements. However, a commonly employed option is a layer of zinc or zinc-alloy coating, known as galvanized coating. This particular coating offers exceptional defense, significantly prolonging the lifespan of the steel sheets and rendering them suitable for a wide range of industries and applications.

Send your message to us

Best COATED GALVANIZED CORRUGATED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords