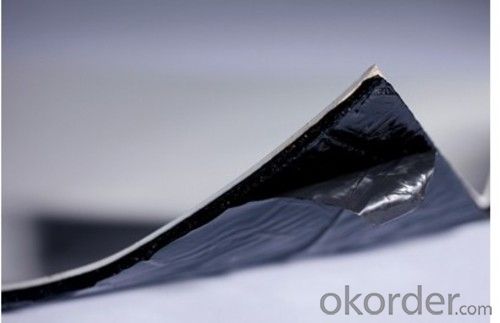

EPDM Waterproofing Rubber Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Application Range

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes resistant to frost damage?

- Waterproofing membranes, in general, exhibit resistance towards frost damage. These membranes are specifically crafted to endure diverse weather conditions, which include freezing temperatures. They typically comprise modified bitumen, PVC, EPDM, or TPO, materials renowned for their exceptional frost and environmental resistance. These materials are engineered to maintain their flexibility and elasticity, even in low temperatures, ensuring the preservation of the waterproofing membrane's effectiveness in preventing water infiltration. Furthermore, meticulous installation methods and regular maintenance can augment the waterproofing membranes' resistance to frost damage.

- Q: Are there different waterproofing membrane options for above-ground and below-ground applications?

- Yes, there are different waterproofing membrane options for above-ground and below-ground applications. Above-ground waterproofing membranes are typically designed to protect structures from moisture and weather elements, such as rain and UV rays. These membranes are often more focused on preventing water intrusion from the outside. On the other hand, below-ground waterproofing membranes are specifically designed to resist the hydrostatic pressure exerted by groundwater. They are more robust and are often used in basements, foundations, and other below-grade applications to prevent water penetration from the soil.

- Q: Can a waterproofing membrane be used for shopping malls or commercial buildings?

- Yes, a waterproofing membrane can be used for shopping malls or commercial buildings. Waterproofing membranes are commonly used in construction to provide a protective barrier against water infiltration, which is crucial for the longevity and maintenance of buildings. They are particularly effective in areas prone to heavy rainfall or where water exposure is a concern, making them suitable for shopping malls and commercial buildings where water damage can be costly and disruptive.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Yes, a waterproofing membrane can be used for theaters or concert halls. Waterproofing membranes are commonly used in construction to protect buildings from water damage. The membrane can be applied to various surfaces, including walls, floors, and roofs, helping to prevent water penetration and moisture-related issues. In theaters or concert halls, where there may be a significant risk of water damage due to heavy rain, leaks, or potential spills, using a waterproofing membrane can provide an extra layer of protection and help preserve the structural integrity of the building.

- Q: Can a waterproofing membrane be used on tunnels with subway systems?

- Tunnels with subway systems can indeed benefit from the use of a waterproofing membrane. It is strongly advised to incorporate this protective layer into subway tunnel construction to prevent water infiltration and potential harm to the structure and electrical systems. The waterproofing membrane acts as a barrier, effectively excluding water and safeguarding the tunnel against issues caused by moisture, such as corrosion, mold, and deterioration. It is crucial to select a waterproofing membrane that is specially designed for tunnel use and capable of withstanding the unique challenges and conditions of subway systems, including heavy traffic loads, vibrations, and exposure to chemicals. Moreover, it is essential to ensure the installation of the waterproofing membrane is carried out by experienced professionals who adhere to the appropriate guidelines and specifications, guaranteeing its effectiveness and durability.

- Q: Can waterproofing membranes be used on concrete surfaces?

- Concrete surfaces can indeed benefit from the use of waterproofing membranes. These membranes are specifically designed to create a barrier against water penetration. They are often employed on concrete surfaces to safeguard them against water damage. Typically, these membranes are composed of rubber, PVC, or bitumen and can be applied to the concrete surface either in a liquid or sheet form. Once applied, the membrane forms a strong and continuous waterproof layer that effectively prevents water from seeping into the concrete. This proves to be particularly advantageous in areas that frequently come into contact with water, such as basements, bathrooms, or outdoor concrete structures. By preventing water-related issues such as cracking, spalling, or mold growth, waterproofing membranes effectively prolong the lifespan of concrete surfaces.

- Q: Can waterproofing membranes be applied on roofs?

- Yes, waterproofing membranes can be applied on roofs. In fact, they are commonly used in the construction industry to provide an extra layer of protection against water infiltration. These membranes are typically made of synthetic materials such as PVC, TPO, or EPDM, which are highly resistant to water and can effectively prevent leaks and water damage on roofs. The application of waterproofing membranes on roofs is a proven method to enhance the longevity and durability of the roofing system, especially in areas prone to heavy rainfall or extreme weather conditions. Additionally, waterproofing membranes are flexible and can be easily installed on various types of roofing materials, including concrete, metal, or asphalt shingles. Therefore, if you want to ensure a watertight roof and protect your property from water-related issues, using waterproofing membranes is a reliable and effective solution.

- Q: Roof SBS waterproofing membrane can not empty shop

- Whether the waterproofing membrane is empty is determined by two aspects. 1, the construction site requirements. Such as the basement of the bottom of the membrane waterproof specifications require empty shop; deformation of the steel roof can be a small amount of sticky open shop or shop shop to adapt to structural deformation, but the coil to have a certain pressure.

- Q: Can waterproofing membranes be used on concrete slabs?

- Yes, waterproofing membranes can be used on concrete slabs. In fact, it is a common practice to apply waterproofing membranes to concrete slabs to protect them from water damage. Waterproofing membranes are designed to create a barrier that prevents water from penetrating the concrete surface. This is especially important for areas that are exposed to moisture, such as basements, balconies, or swimming pools. By applying a waterproofing membrane, the concrete slab is protected from water infiltration, which can lead to cracks, erosion, or mold growth. Additionally, waterproofing membranes can also enhance the overall durability and lifespan of the concrete slab.

- Q: Can a waterproofing membrane be used on copper surfaces?

- Indeed, copper surfaces can be prone to corrosion and moisture-related damage. In order to safeguard them, it is possible to utilize a waterproofing membrane. By implementing this measure, an extra level of protection is afforded. The membrane serves as a barrier, effectively preventing water and moisture from infiltrating the copper surface. Consequently, corrosion is impeded and the lifespan of the copper material is extended. It is crucial to exercise caution when selecting a compatible waterproofing membrane to ensure optimal adhesion and efficacy. Furthermore, it is imperative to diligently adhere to appropriate surface preparation and application techniques to guarantee a triumphant waterproofing solution for copper surfaces.

Send your message to us

EPDM Waterproofing Rubber Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords