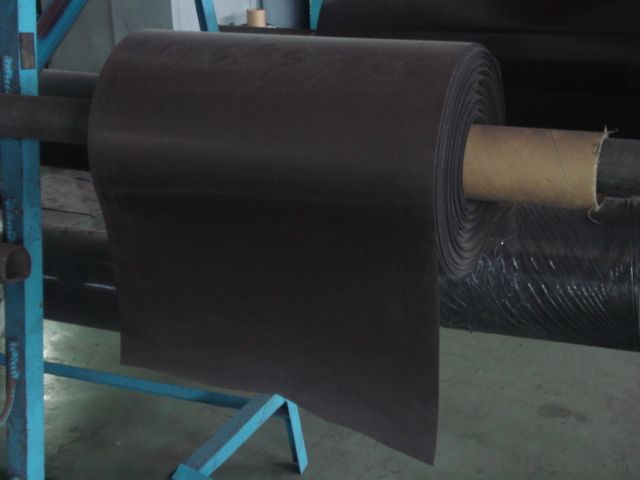

EPDM Waterproof Rubber Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

The flexible roofing system has been mature history for several years in the world, especially in the large workshop, warehouse, logistics and other roof has been widely used. Its structure is simple and clear: pressure plate structure of gas isolation - insulation waterproof, each function of each level divided the whole roof; waterproof layer for the whole roof from the erosion of rainwater, so waterproof material excellent in the flexible roofing.

Our EPDM waterproofing membrane, is one of the world's advanced waterproof material, it not only has three Yuan rubber weather resistance, good aging resistance; lap joint can also be hot air welding, overcomes three EPDM coiled material adhesive construction is complex, so that the joint is more solid water quality is more reliable.

Product features

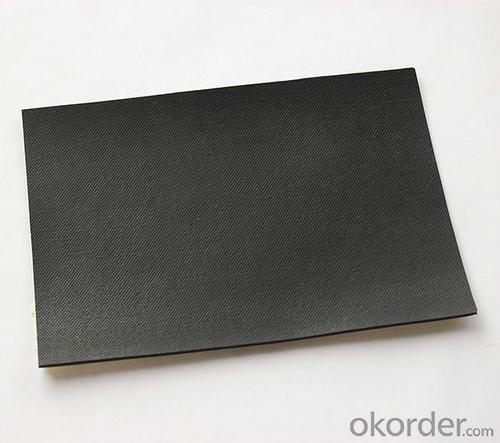

The physical and mechanical properties of stability, durability and anti ageing capacity is good, its oil and solvent resistance and general-purpose chloroprene rubber be roughly the same.

1 Good heat resistance, cold resistance, can be in (-60-150 C) within the scope of use.

2 Extension and rate very high tear strength, shrinkage cracking of buildings or a strong ability to adapt.

3 The proportion of light (0.90~0.97), the appearance of uniform quality, has good flexibility and elasticity.

4 Good weldability, materials can be directly welded, is conducive to ensure weld quality. After welding to form an integral waterproof layer.

5 Good dimensional stability, heat shrinkage is small, the deformation is small, keep a good state during construction.

6 Environmental protection type. Does not produce harmful substances in the production, construction and use of the process, and can be recycled, does not produce construction waste.

Application arrange

Applicable to all kinds of roofing, basement, tunnel, building waterproof engineering; civil and industrial building roofs and underground engineering, municipal, bridges, storage tank,

Waterproof subway, tunnel, dam engineering, especially suitable for durability, corrosion resistance requirements and easy deformation of the key waterproof engineering.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for a swimming pool deck coating?

- Yes, a waterproofing membrane can be used for a swimming pool deck coating. A waterproofing membrane is designed to prevent water penetration and protect the underlying surfaces. When applied correctly, a waterproofing membrane can create an effective barrier against water and moisture, making it an ideal choice for a swimming pool deck coating. It can help prevent water damage, such as cracking, spalling, or deterioration, and also provide a non-slip surface for added safety. Additionally, a waterproofing membrane can help extend the lifespan of the pool deck by protecting it from water-related issues. Overall, using a waterproofing membrane for a swimming pool deck coating is a practical and beneficial choice.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Yes, a waterproofing membrane can be used in areas with extreme weather conditions, such as hurricanes or snowstorms. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively withstand various weather conditions. They are made from materials that are resistant to moisture and can be installed in different areas like roofs, basements, or foundations. In regions prone to hurricanes, waterproofing membranes can help prevent water damage by creating a barrier that keeps water out even during heavy rainfall or storm surges. These membranes are often reinforced and have high tensile strength to withstand the strong winds and pressure associated with hurricanes. Similarly, in areas with heavy snowstorms, waterproofing membranes can help prevent water intrusion caused by melting snow or ice dams. They are designed to be flexible and resistant to extreme temperatures, ensuring that they maintain their integrity and prevent leaks even in freezing conditions. However, it is important to choose the right type of waterproofing membrane suitable for the specific weather conditions in the area. Different membranes have varying levels of resistance to extreme weather, so it is advisable to consult with a professional to determine the most appropriate membrane for the specific climate and weather patterns. Additionally, proper installation and regular maintenance are crucial to ensure the longevity and effectiveness of the waterproofing system in extreme weather conditions.

- Q: Can a waterproofing membrane be used in areas with high humidity and moisture?

- Yes, a waterproofing membrane can be used in areas with high humidity and moisture. In fact, it is specifically designed to prevent water infiltration and protect the underlying structure from damage caused by moisture. Waterproofing membranes are commonly used in areas such as basements, bathrooms, and kitchens, where the presence of moisture and humidity is more pronounced. These membranes create a barrier that prevents water from seeping through walls, floors, or roofs, and they are typically made of materials like rubber, asphalt, or PVC. By installing a waterproofing membrane, you can effectively manage moisture levels and protect your property from potential water damage, mold growth, and other related issues.

- Q: Can a waterproofing membrane be used on roofs with flat surfaces?

- Roofs with flat surfaces can indeed benefit from the application of a waterproofing membrane. In fact, it is quite common to use these membranes on flat roofs to safeguard against water infiltration. The primary function of these membranes is to establish a barrier that obstructs water from seeping into the roof structure and causing harm. Typically, they are constructed using materials like modified bitumen, EPDM, or PVC, which exhibit great resistance to both water and UV rays. To install the membrane, it can be done by torch-application, adhesive adherence, or mechanical fastening. To ensure optimal effectiveness and longevity of the waterproofing membrane on a flat roof, it is crucial to guarantee proper installation and regular maintenance.

- Q: Does a waterproofing membrane provide any UV resistance?

- Yes, a waterproofing membrane can provide some level of UV resistance. Many waterproofing membranes are designed to withstand exposure to sunlight and UV rays, which can cause degradation and damage over time. These membranes are often formulated with UV stabilizers or additives that help protect against UV radiation, prolonging their lifespan and maintaining their effectiveness in providing waterproofing protection. However, the level of UV resistance may vary depending on the specific type and quality of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for plant rooms and mechanical equipment areas?

- Yes, a waterproofing membrane can be used for plant rooms and mechanical equipment areas. These areas often require protection from water and moisture damage, and a waterproofing membrane can provide an effective barrier to prevent leaks and water infiltration.

- Q: Can a waterproofing membrane be used in new construction?

- A waterproofing membrane is capable of being utilized in new construction. In fact, it is frequently advised to incorporate a waterproofing membrane during the construction phase to furnish an extra layer of safeguard against water harm. Typically, waterproofing membranes are administered to the external foundation walls and basement floors to obstruct water infiltration and construct a barrier against moisture. This can effectively avert predicaments like leaks, mold, and structural damage in the long run. Furthermore, waterproofing membranes can also be employed in other areas of a new construction project, such as roofs, balconies, and bathrooms, to guarantee long-lasting waterproofing protection. On the whole, the utilization of a waterproofing membrane in new construction can contribute to the extension of the building's lifespan and instill peace of mind for its occupants.

- Q: Can a waterproofing membrane be used on gypsum block surfaces?

- Gypsum block surfaces can benefit from the use of a waterproofing membrane. These surfaces are porous and can absorb moisture, making them naturally non-waterproof. By applying a waterproofing membrane, the infiltration of water, moisture damage, and mold growth on gypsum block surfaces can be prevented. The membrane acts as a barrier, repelling water and keeping it from penetrating the material. However, it is crucial to choose a suitable waterproofing membrane that is specifically designed for use on gypsum blocks and compatible with the particular type of gypsum block being treated. Moreover, to ensure the effectiveness and durability of the waterproofing membrane, proper surface preparation and application techniques must be followed.

- Q: Does a waterproofing membrane require any specific surface preparation?

- Yes, a waterproofing membrane typically requires specific surface preparation before installation. This involves cleaning the surface, removing any loose debris, and ensuring it is smooth and dry. Additionally, some membranes may require priming or the use of specific adhesives depending on the type of surface they are being applied to. Proper surface preparation is crucial to ensure effective adhesion and long-lasting waterproofing performance.

- Q: Are there any limitations to using a waterproofing membrane?

- Yes, there are some limitations to using a waterproofing membrane. One limitation is that the membrane can be punctured or damaged during installation, which can compromise its effectiveness. Additionally, waterproofing membranes may not be suitable for all types of surfaces or structures, and certain conditions such as extreme temperatures or excessive movement can affect their performance. Moreover, the lifespan of a waterproofing membrane can vary depending on factors like maintenance, exposure to UV rays, and overall wear and tear.

Send your message to us

EPDM Waterproof Rubber Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords