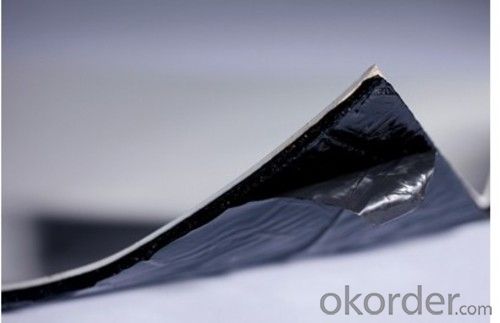

EPDM Waterproofing Membrane Roll Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction:

This waterproof membrane is made from ternary ethylene-propylene rubber. Weadopts the world advanced equipment of cold feeding extrusion and continuous valcanization technology.

With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1)Good flexibility, creep properties and malleability, and the superior adapting ability to the deformation of the primary stress generated.

2). Tight adhesion between waterproof layer and basic layer, no channeling water. Having self healing ability after piercing.

3).Operation without heating. And possessing the reliability of pasting by itself with super strong connection of sheet materialand adhesion of same base.

4). Convenient and safe operation, no pollution to the environment.

Application:

1),Roofs, Basement, Toilet

2),Industrial and civil building waterproofing

3),Geosynthetic liner for swimming pool, channels, irrigation system

4),Especially suit for projects with high requirements in durability, anti-corrosion anddeformation

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be removed or replaced if necessary?

- If necessary, one can remove or replace a waterproofing membrane. Over time, these membranes may deteriorate or sustain damage, resulting in leaks or moisture seepage. In such instances, it becomes necessary to remove the current membrane and install a new one to ensure effective waterproofing. This removal and replacement process entails meticulously peeling away the old membrane, cleansing the surface, and applying a fresh membrane system. Consulting a skilled waterproofing contractor is crucial as they can evaluate the condition of the existing membrane and offer suitable guidance for its removal and replacement.

- Q: Can a waterproofing membrane be applied on a vertical surface?

- Yes, a waterproofing membrane can be applied on a vertical surface. Waterproofing membranes are designed to create a barrier against water penetration, whether it is applied horizontally or vertically. They are commonly used on vertical surfaces such as walls, retaining walls, and foundations to prevent water damage and leakage.

- Q: Are waterproofing membranes resistant to salt damage?

- Yes, waterproofing membranes are generally resistant to salt damage. They are designed to protect against moisture and other environmental factors, including saltwater. The membranes are specifically engineered to provide a barrier that prevents water and salts from infiltrating and causing damage to underlying structures.

- Q: Can a waterproofing membrane be used for plaza decks?

- Yes, a waterproofing membrane can be used for plaza decks. Plaza decks are typically outdoor spaces that require protection from water infiltration to prevent damage to the underlying structure. Waterproofing membranes are designed to create a barrier that prevents water from seeping into the deck and causing issues such as leaks, deterioration, and structural damage. These membranes are often made of materials such as bitumen, rubber, or polyurethane, which are highly resistant to water penetration. By installing a waterproofing membrane on a plaza deck, it ensures that the deck remains watertight and protects the integrity of the entire structure. Additionally, these membranes can also provide added benefits such as UV resistance, durability, and ease of maintenance, making them an ideal solution for plaza decks.

- Q: Do you know how many square meters of waterproofing membrane to send a set of tests?

- Elastomer Asphalt Waterproofing Sheets: Take a roll out of the outer roll head 2500mm, the vertical cut 800mm full-width coil sample 2. 10000 square meters for a group, the lack of a group also.

- Q: Can waterproofing membranes be used on plant rooms?

- Yes, waterproofing membranes can be used on plant rooms. Waterproofing membranes are often used in areas where water resistance is necessary, such as basements, roofs, and plant rooms. Plant rooms typically house various mechanical and electrical equipment, and using waterproofing membranes can help protect these sensitive components from water damage.

- Q: Can a waterproofing membrane be installed by a homeowner or is professional installation required?

- Professional installation is typically recommended for waterproofing membrane installation. This is because it involves complex techniques and specialized equipment that homeowners may not have. Additionally, professionals are trained to assess and address specific waterproofing needs, ensuring a more reliable and effective installation.

- Q: Are waterproofing membranes resistant to alkali exposure?

- Yes, waterproofing membranes are generally resistant to alkali exposure. They are designed to provide a barrier against moisture, which includes protection against alkali substances commonly found in construction materials such as concrete.

- Q: Are there any specific considerations for installing a waterproofing membrane on precast concrete surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on precast concrete surfaces. Here are a few key points to keep in mind: 1. Surface Preparation: Before applying the waterproofing membrane, it is crucial to prepare the precast concrete surface properly. This may involve cleaning the surface, removing any loose particles, and ensuring that it is dry and free from any contaminants. 2. Compatibility: It is important to choose a waterproofing membrane that is compatible with precast concrete surfaces. Some membranes may not adhere well or may not provide effective waterproofing on this type of substrate. Therefore, it is essential to select a membrane specifically designed for use on precast concrete. 3. Adhesion: Ensuring proper adhesion of the waterproofing membrane to the precast concrete surface is vital. The manufacturer's instructions should be followed carefully, including any surface priming or preparation requirements for optimal adhesion. Proper adhesion will help prevent any water infiltration or damage to the concrete. 4. Joint Treatment: Precast concrete surfaces often have joints between panels or other components. These joints need to be properly treated to maintain the waterproofing integrity of the system. This may involve using joint sealants or tapes specifically designed for waterproofing purposes. 5. Durability: Consider the durability and longevity of the waterproofing membrane. Precast concrete surfaces are often exposed to various weather conditions and environmental factors. Therefore, it is crucial to select a membrane that can withstand these conditions and provide long-term protection against water penetration. 6. Quality Assurance: It is recommended to work with experienced professionals or certified installers to ensure the proper installation of the waterproofing membrane on precast concrete surfaces. This will help to minimize any potential installation errors and ensure that the waterproofing system performs as intended. By considering these specific considerations, the installation of a waterproofing membrane on precast concrete surfaces can help protect the concrete from water damage and extend its lifespan.

- Q: Does a waterproofing membrane require any specific primers or bonding agents for installation?

- Yes, a waterproofing membrane typically requires specific primers or bonding agents for proper installation. These primers or bonding agents are necessary to ensure proper adhesion and create a strong bond between the membrane and the substrate, enhancing the effectiveness and longevity of the waterproofing system.

Send your message to us

EPDM Waterproofing Membrane Roll Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords