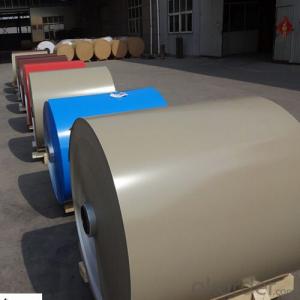

Painted Aluminum Coils - EN AW-5183 Aluminum Sheet with Blue PE Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 5183 Aluminium Sheet With Blue PE Film Description

EN AW - 5183 Aluminium Sheet With Blue PE Film is one semi-finished aluminium material. This sheet can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5183 Aluminium Sheet With Blue PE Film

EN AW - 5183 Aluminium Sheet With Blue PE Film | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5183 Aluminium Sheet With Blue PE Film

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5183 Aluminium Sheet With Blue PE Film

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5183 Aluminium Sheet With Blue PE Film

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

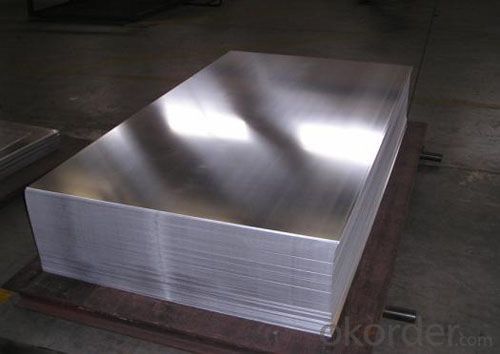

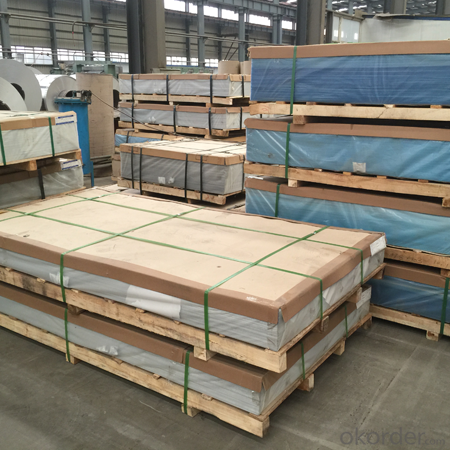

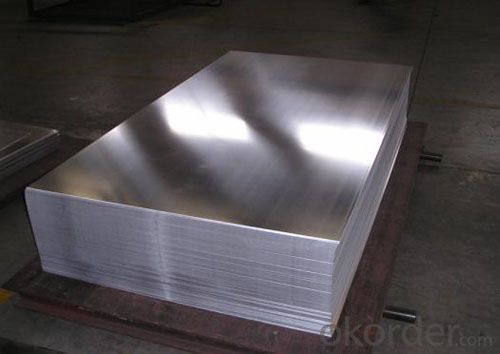

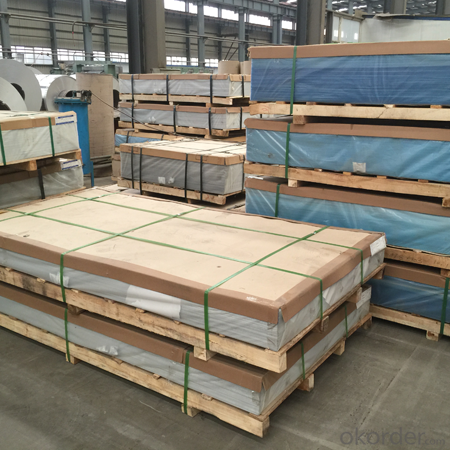

6. Image of EN AW - 5183 Aluminium Sheet With Blue PE Film

7. Package and shipping of EN AW - 5183 Aluminium Sheet With Blue PE Film

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it safe or practical to use an electric iron as a heat source for an aluminum coil?

- <p>Using an electric iron to heat an aluminum coil is not advisable. Electric irons are designed to heat their own plates for ironing clothes, not to transfer heat to other materials like aluminum coils. The high temperature of an iron could damage the coil and potentially cause a fire hazard. Moreover, aluminum has a high thermal conductivity, which means it would dissipate heat quickly, making it inefficient to use an iron for this purpose. Always use heating elements specifically designed for the material you intend to heat.</p>

- Q: Can aluminum coils be used in the production of electronic components?

- Yes, aluminum coils can be used in the production of electronic components. Aluminum is a commonly used material due to its lightweight, conductivity, and corrosion resistance properties. It is often used in electronic devices such as capacitors, inductors, and transformers.

- Q: This question asks for an explanation of the various materials used for coating aluminum coils.

- <p>Aluminum coil coating materials can be categorized into several types, including: 1. Organic coatings, such as polyester, acrylic, and polyvinylidene fluoride (PVDF), which offer good weather resistance and color stability. 2. Inorganic coatings, like fluoropolymers, which provide exceptional chemical resistance and high-temperature stability. 3. Metal coatings, such as zinc or other metals, used for enhanced corrosion resistance. 4. Ceramic coatings, which are known for their high durability and resistance to heat and chemicals. 5. Laminates, which combine multiple materials for specific performance characteristics. These coatings are chosen based on the intended application of the aluminum coil, such as in construction, automotive, or packaging industries.</p>

- Q: The export of aluminum coil, according to steel coil declaration, will there be any problems?

- If you have already declared itCheck the corresponding HS code, to import countries taxes and fees are the same, whether the customer side mind?.China's tax rebate rate, you also see what kind of high?.In addition to export will have a steel coil sampling, aluminum volume difference is relatively large, so if the declaration, to take note of this, if the sampling try with conversational communication forwarding, otherwise it would be a big problem.

- Q: The choice between Vinyl and Aluminum? By Mastercraft Exteriors

- Vinyl. Aluminum dents, and the paint can be scratched off. Vinyl pops back, and the color goes all the way through.

- Q: When the aluminum roll is rolled 0.14, when the coil is taken off, what happened to the loose layer?

- in addition is a kind of expression is down when the aluminum coil suddenly becomes uneven, but the bad effect caused by oil

- Q: Can aluminum coils be insulated?

- Yes, aluminum coils can be insulated. Insulation is commonly applied to aluminum coils to improve energy efficiency and prevent condensation and heat loss in various HVAC systems.

- Q: How much is one ton of aluminum coil?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.If you have any questions, please ask. I hope to help you.

- Q: I am trying to electropolish the surface of a 3003 aluminum sample to analyze in the SEM. I was wondering if anyone knew what electrolyte and electropolishing paramaters work for this alloy. So far I have used phosporic+ethanol+water at 50V for 2 minutes with minimal success.

- Aluminium needs deoxidizing also called as desmutting after electropolishing. This is done in a hot chromic acid bath for nearly for 5 minutes.

- Q: What are the common quality control measures for aluminum coil manufacturing?

- Some common quality control measures for aluminum coil manufacturing include visual inspections to check for any defects or imperfections in the coils, dimensional measurements to ensure they meet the required specifications, chemical analysis to verify the composition and purity of the aluminum, mechanical testing to assess the strength and durability of the coils, and surface finish evaluations to ensure a smooth and uniform appearance. Additionally, manufacturers may implement statistical process control techniques to monitor and control the production process to consistently produce high-quality aluminum coils.

Send your message to us

Painted Aluminum Coils - EN AW-5183 Aluminum Sheet with Blue PE Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords