Aluminum Sheet Metal Coil - EN AW 5050 Aluminium Coil for Refrigerator Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW 5050 Aluminium in Coil Form for Refrigerator Panel Description

EN AW 5050 Aluminium in Coil Form for Refrigerator Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW 5050 Aluminium in Coil Form for Refrigerator Panel

EN AW 5050 Aluminium in Coil Form for Refrigerator Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW 5050 Aluminium in Coil Form for Refrigerator Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW 5050 Aluminium in Coil Form for Refrigerator Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW 5050 Aluminium in Coil Form for Refrigerator Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

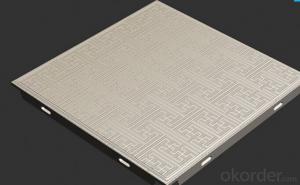

6. Image of EN AW 5050 Aluminium in Coil Form for Refrigerator Panel

7. Package and shipping of EN AW 5050 Aluminium in Coil Form for Refrigerator Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What will be the pros and cons of using each of these materials?One thing to keep in mind is that aluminum alloys are good conductors of electricity.

- Aluminum is strong and lighter, but not electrically safe. Fiberglass is safe for electrical work and strong, but susceptible to sun damage, and can give out due to cracking. Wood will wear out, and is also damaged by weather, but is safe with electricity.

- Q: What are the common alloys used in aluminum coil production?

- The common alloys used in aluminum coil production are 3003, 3105, 5052, and 6061.

- Q: Can aluminum coils be used in the production of aluminum facades?

- Aluminum facades can indeed utilize aluminum coils. Within the construction industry, aluminum coils find frequent usage in multiple applications, with facade production being one of them. These coils are typically crafted from top-notch aluminum alloy, boasting exceptional attributes like durability, resistance to corrosion, and aesthetic allure. To craft the desired design and size for aluminum facades, these coils are effortlessly moldable, cuttable, and formable. Moreover, the option to coat the aluminum coils with diverse finishes, such as powder coating or anodizing, provides added protection and elevates the facades' overall appearance. Consequently, aluminum coils emerge as a flexible and dependable material choice for aluminum facades, offering an extensive array of design possibilities and long-lasting performance.

- Q: What is the typical coefficient of friction for aluminum coils?

- The typical coefficient of friction for aluminum coils can vary depending on various factors such as the surface conditions, lubrication, and the specific type of aluminum alloy used. However, in general, the coefficient of friction for aluminum coils is relatively low compared to other materials. It typically falls within the range of 0.1 to 0.4.

- Q: Can aluminum coils be used in marine applications?

- Yes, aluminum coils can be used in marine applications. Aluminum is a corrosion-resistant metal that provides excellent durability and strength, making it suitable for various marine environments. It is commonly used in boat building, marine equipment, and other marine applications due to its lightweight nature and resistance to saltwater corrosion.

- Q: What are the different packaging options for aluminum coils?

- There are various packaging options available for aluminum coils to ensure their safety and convenience during transportation and storage. Some common packaging options include: 1. Wooden Crates: Aluminum coils are often packaged in wooden crates, which provide excellent protection against impacts and ensure the coils remain intact during transit. The crates are typically reinforced with steel bands for added strength and stability. 2. Cardboard Boxes: Smaller aluminum coils or coils intended for retail purposes are often packaged in cardboard boxes. These boxes are lightweight, cost-effective, and provide moderate protection against minor impacts. 3. Plastic Wrapping: Aluminum coils can also be wrapped in plastic film, which helps protect them from moisture, dust, and scratches. This packaging option is commonly used for coils that are transported in bulk or in situations where additional packaging is not required. 4. Metal or Composite Tubes: In some cases, aluminum coils are packaged in metal or composite tubes. These tubes are sturdy and provide excellent protection against external forces. They are often used for coils with large diameters or longer lengths. 5. Customized Packaging: Depending on the specific requirements of the customer or industry, customized packaging options can be designed. This may include the use of foam or cushioning materials to provide additional protection, or the incorporation of specialized features such as moisture-resistant barriers. It is important to choose packaging options that best suit the specific needs of the aluminum coils, considering factors such as coil size, weight, transportation conditions, and storage requirements.

- Q: Can aluminum coils be used in high-magnetic field applications?

- Yes, aluminum coils can be used in high-magnetic field applications. Aluminum is a non-magnetic material, which means it does not have any magnetic properties. This makes it suitable for use in high-magnetic field applications where the presence of a magnetic field could interfere with the performance or function of the coils. Aluminum coils are commonly used in various industries, including electrical engineering, aerospace, and automotive, where high-magnetic fields are encountered. Additionally, aluminum is lightweight and has good electrical conductivity, making it an ideal choice for applications requiring efficient and lightweight coil designs.

- Q: What are the different coil edge profiles available for aluminum coils?

- There are several different coil edge profiles available for aluminum coils. Some of the most common ones include: 1. Slit edge: This is the most basic type of edge profile, where the coil is simply slit to the desired width. The edges of the coil are typically sharp and can be prone to burrs or roughness. 2. Deburred edge: In this profile, the edges of the coil are deburred to remove any sharp or rough edges. Deburring helps to improve safety and prevents damage to downstream equipment during processing. 3. Rounded edge: This profile features rounded edges, which are achieved by rolling or machining the edges of the coil. Rounded edges are often preferred in applications where safety is paramount or where the coil will be subjected to frequent handling. 4. Beveled edge: Beveled edge profiles are created by cutting or grinding the edges of the coil at an angle. This profile is commonly used in applications where two coils need to be joined together, as the beveled edges allow for a smoother and more secure connection. 5. Custom edge profiles: Depending on the specific requirements of the application, custom edge profiles can be developed. These profiles are tailored to meet the unique needs of the customer and may involve a combination of different edge treatments. It is important to note that the choice of coil edge profile depends on the intended application, processing requirements, and desired aesthetic appearance. Manufacturers and suppliers of aluminum coils often offer a range of edge profiles to meet various customer needs.

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular and commonly used material for roofing due to its durability, lightweight nature, and resistance to corrosion. It is often chosen for its ability to withstand harsh weather conditions and its long lifespan, making it a suitable option for various roofing applications.

- Q: I would like to know because I'm getting a sword with an aluminum sheathe.

- No, it is a very soft metal. However for a sheath it will likely be fine, unless you intend on practicing using the sheath for blocking as some Samurai used it for.

Send your message to us

Aluminum Sheet Metal Coil - EN AW 5050 Aluminium Coil for Refrigerator Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords