China Color Coated Aluminum Coil - EN AW-5005 Slitted Aluminum Coil with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 5005 Slitted Aluminium Coil With Good Quality Description

EN AW - 5005 Slitted Aluminium Coil With Good Quality is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5005 Slitted Aluminium Coil With Good Quality

EN AW - 5005 Slitted Aluminium Coil With Good Quality | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5005 Slitted Aluminium Coil With Good Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5005 Slitted Aluminium Coil With Good Quality

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5005 Slitted Aluminium Coil With Good Quality

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

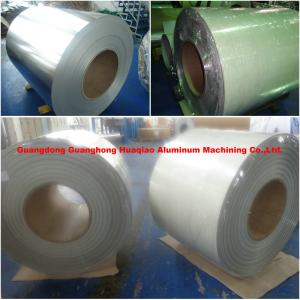

6. Image of EN AW - 5005 Slitted Aluminium Coil With Good Quality

7. Package and shipping of EN AW - 5005 Slitted Aluminium Coil With Good Quality

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the typical delivery options for aluminum coils?

- The typical delivery options for aluminum coils include shipping via truck, rail, or ocean freight. Additionally, local pickup may also be available for customers located near the manufacturing facility or distribution center.

- Q: How are aluminum coils used in the production of HVAC ductwork?

- The production of HVAC ductwork heavily relies on the utilization of aluminum coils. These coils are crafted from top-notch aluminum material that possesses qualities such as being lightweight, long-lasting, and resistant to corrosion, thus making them the perfect choice for HVAC systems. To commence the process of incorporating aluminum coils into HVAC ductwork production, the first step involves manufacturing. Initially, the coils are rolled into thin sheets, which are then precisely cut into specific widths and lengths that match the size requirements of the ductwork. This adaptability in sizing allows for the creation of customized ductwork that fits flawlessly into various HVAC systems. Once the aluminum coils have been cut to the desired dimensions, they are then fashioned into the shape of the ductwork. This can be achieved through a variety of methods, including bending, folding, or rolling, depending on the design and specifications of the ductwork. One of the notable advantages of employing aluminum coils in HVAC ductwork production is their superb thermal conductivity. Aluminum boasts exceptional heat-conducting properties, which means it can effectively transfer heat or cold air throughout the HVAC system. This characteristic is crucial for the proper functionality of the ductwork, as it ensures the desired temperature is maintained in different areas of a building. Furthermore, aluminum coils are renowned for their resistance to corrosion, which is of utmost importance in HVAC systems. The coils are exposed to various elements, such as moisture, which can lead to rust and deterioration in other materials. However, aluminum naturally forms a protective oxide layer that prevents corrosion, guaranteeing the longevity and dependability of the HVAC ductwork. Additionally, the lightweight nature of aluminum coils makes them simple to handle and install. This decreases the labor and time required for ductwork installation, resulting in cost savings for both manufacturers and installation teams. Moreover, the lightweight nature of aluminum coils reduces the overall weight of the HVAC system, making it more energy-efficient and alleviating strain on other components. In conclusion, aluminum coils serve as an integral component in the production of HVAC ductwork. Their lightweight, durable, and corrosion-resistant properties, combined with exceptional thermal conductivity, render them ideal for efficiently circulating air throughout the HVAC system. Furthermore, their flexibility in sizing and ease of installation contribute to their widespread utilization in the HVAC industry.

- Q: How do I write ionic formula for Sodium Aluminum Silicate? Please explain in a easy way ,,,,,,,,,,,,

- There are literally thousands of different kinds of sodium aluminum silicate, and they do not have simple formulas, because the aluminum and silicon form giant oxygen bridged anions. Most clay minerals are of this type, more or less, although potassium is more common in clays than sodium. So there is no easy way. The empirical formula is sometimes written as a ratio of Na2O to Al2O3 to SiO2, but this gives no information about the structure, only the overall composition. Look up clay minerals online. Wikipedia might be a good start. Also the website mentioned in the other answer.

- Q: Describe the various uses of aluminum coils in the manufacturing industry.

- <p>Aluminum coils are widely used in manufacturing due to their lightweight, corrosion resistance, and strength. They are utilized in the production of various products such as automotive parts, aerospace components, and construction materials. Aluminum coils are also employed in the manufacturing of electrical wiring, heat exchangers, and packaging materials. Additionally, they are used in the production of cans and foils for food and beverage industries. Their versatility makes aluminum coils an essential material in many manufacturing processes.</p>

- Q: How are aluminum coils priced in the market?

- Aluminum coils are priced in the market based on several factors. The primary factor influencing the price of aluminum coils is the current market price of aluminum. Since aluminum is a commodity, its price is determined by global supply and demand dynamics, as well as factors like production costs and currency fluctuations. Additionally, the cost of processing and manufacturing aluminum coils also affects their pricing. This includes expenses such as refining, alloying, rolling, and any other specialized processes required to produce the coils. The cost of energy, labor, and raw materials used in the production process also contribute to the overall pricing. Furthermore, market competition and the overall demand for aluminum coils influence their pricing. If there is high demand for aluminum coils and limited supply, the prices are likely to be higher. Conversely, if there is low demand and excess supply, prices may be lower. The size, thickness, and quality of the aluminum coils also play a role in determining their price. Thicker, larger, and higher-quality coils generally command a higher price due to the increased material and processing costs involved. Finally, transportation costs, import/export duties, and taxes imposed by different countries can also impact the pricing of aluminum coils. These additional costs are often factored into the final price of the product. In summary, the pricing of aluminum coils in the market is influenced by the current market price of aluminum, production costs, market competition, demand and supply dynamics, size and quality of the coils, as well as additional costs associated with transportation and taxes.

- Q: What are the common joining techniques used for aluminum coils?

- The common joining techniques used for aluminum coils include welding, adhesive bonding, mechanical fastening, and soldering. Welding is a widely used joining technique for aluminum coils. Different welding methods, such as gas tungsten arc welding (GTAW or TIG), gas metal arc welding (GMAW or MIG), and laser welding, can be employed to fuse the aluminum coils together. Welding provides a strong and durable joint, ensuring structural integrity. Adhesive bonding is another technique used for joining aluminum coils. It involves the application of a suitable adhesive or bonding agent to join the coils together. Adhesive bonding offers excellent flexibility, as it can join dissimilar materials and create a smooth, aesthetically pleasing surface. Moreover, it distributes stress evenly across the joint, reducing the risk of fatigue failure. Mechanical fastening involves the use of mechanical elements like bolts, screws, rivets, or clips to join the aluminum coils together. This method is relatively simple and cost-effective, allowing for easy disassembly if needed. Mechanical fasteners provide good strength and stability but may require periodic maintenance to prevent loosening over time. Soldering is a technique that uses a low-temperature alloy to join aluminum coils. It involves heating the solder to its melting point and allowing it to flow into the joint, creating a strong bond. Soldering is commonly used for electrical connections or delicate applications where excessive heat can damage the aluminum. However, it may not provide the same strength as welding or mechanical fastening. The choice of joining technique for aluminum coils depends on various factors, including the specific application requirements, desired strength, appearance, and cost considerations.

- Q: Are there any limitations to the maximum coil diameter of aluminum coils?

- Yes, there are limitations to the maximum coil diameter of aluminum coils. The maximum diameter is typically determined by various factors such as the size and capacity of the manufacturing equipment, transportation restrictions, and the practical limitations of handling larger coils.

- Q: I have a 1994 Impala SS with a 5.7L lt1 engine with cast iron heads. Which is better in horsepower gain? Aluminum heads or cast iron heads? People say cast iron heads downsize the hp from 300 to 260 hp. Also which of the two heads are more durable and less restrictive?

- only difference is weight and aluminum is easier to repair

- Q: What are the different protective film options for aluminum coils?

- There are several protective film options available for aluminum coils, each offering specific benefits and suitability for different applications. Some common options include: 1. PVC (Polyvinyl Chloride) Film: PVC films are widely used for protecting aluminum coils due to their excellent resistance to moisture, chemicals, and abrasion. They provide a high level of surface protection and are available in various thicknesses and adhesive strengths. 2. PE (Polyethylene) Film: PE films are another popular choice for protecting aluminum coils. They offer good resistance to moisture and UV radiation and are generally more cost-effective than PVC films. PE films are available in different grades, including low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE). 3. PP (Polypropylene) Film: PP films are known for their excellent tear resistance and high tensile strength. They provide good protection against mechanical damage and are suitable for applications where coils may undergo rough handling or transportation. 4. PET (Polyethylene Terephthalate) Film: PET films offer outstanding clarity and transparency, making them ideal for applications where visual inspection of the coils is required. They also provide good resistance to heat, chemicals, and abrasion. 5. Adhesive Coatings: In addition to films, adhesive coatings are sometimes used to protect aluminum coils. These coatings are typically applied directly to the surface of the coil and form a protective layer against moisture, corrosion, and scratching. When selecting a protective film for aluminum coils, it is essential to consider factors such as the intended application, environmental conditions, handling processes, and desired level of protection. Consulting with a supplier or manufacturer can help determine the most suitable option for specific requirements.

- Q: Are aluminum coils suitable for heat exchanger fins?

- Yes, aluminum coils are suitable for heat exchanger fins. Aluminum has excellent thermal conductivity, lightweight properties, and corrosion resistance, making it an ideal choice for heat transfer applications. Additionally, aluminum coils can be easily formed into various shapes and sizes, allowing for efficient heat exchange in heat exchangers.

Send your message to us

China Color Coated Aluminum Coil - EN AW-5005 Slitted Aluminum Coil with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords