Sublimation Embossed Aluminum Metal Sheets 1xxx3xxx5xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Foil

Often referred to as tin foil, is aluminium prepared in thin metal leaves with a thickness less than 0.2 mm (7.9 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used. In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated to other materials such asplastics or paper to make them more useful. Aluminium foil supplanted tin foil in the mid 20th century.

2.Main Features of the Aluminum Foil

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

6.Our quality is based on EN,ASTM,JIS.

7.We provide free sample service.

8.The products can be made according to your requirement.

9.Sincerely welcome your inquiry.

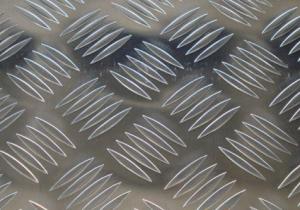

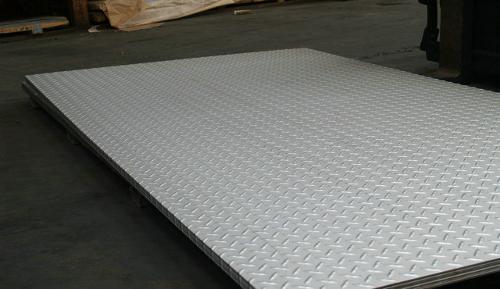

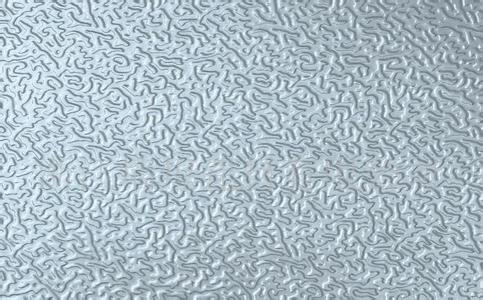

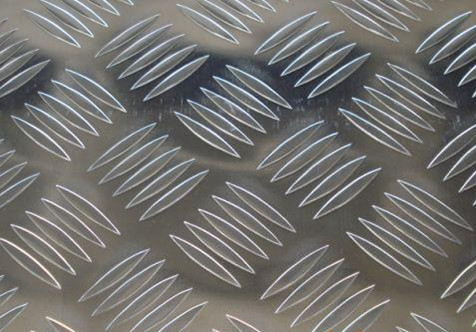

3. Aluminium Foil Images:

4. Aluminium Foil Specification:

Product application range:

Suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

Alloy: 1070\1060\1050\110\1200\1145\1235\3003\3102\8011\8011A\8079\8006

Temper:0/H14\H16\H18\H26\H24\H22

Thickness: 0.006mm_0.2mm

Width: 75 mm-1410 mm

Coil inner diameter: 75.00\ 76.20\ 150.00\ 200.00mm

Aluminum foil coil outer diameter:100 mm-1000 mm

Industry | Type | Typical thickness (mm) | Processing method | Usage |

Packing | Food | 0.006-0.009 | Compound paper, plastics, thin film, embossing & colorizing, printing | Candy, milk and milk product, powder food, drink, tea, bread and all kinds of snack food |

Tobacco | 0.006-0.007 | Compound paper, colorizing, printing | Internal and external packing for cigarette | |

Medicine | 0.006-0.02 | Compounding, coating, printing | Tablet, granular formulation | |

Cosmetics | 0.006-0.009 | Compound printing | ||

Bottle caps | 0.011-0.2 | Printing, scouring printing | Bottle caps, the beer bottle, the fruit juice bottle seal, all kinds of trademarks, etc. | |

Daily use | Household | 0.01-0.2 | Small coiling | Packing for family food etc. |

Utensils | 0...011-0.1 | Molding processing | Food utensils, coal gas hood, ashtray and all kinds of utensils | |

Electrical equipment industry | electrolytic capacitor | 0.015-0.11 | Eroding in the special medium | electrolytic capacitor |

Electrolytic capacitor | 0.006-0.016 | Liner oil paper | capacitor | |

Radiator | 0.09-0.2 | Punching Fin | All kinds of air conditioning radiators | |

Electric cable | 0.15-0.2 | aluminium plastics compound | Electric cable wrap | |

Construction industry | Heat-insulating material | 0.006-0.03 | compound materials | Heat-insulating material for house, pipeline etc. |

Decorating board | 0.03-0.2 | Paints coated compound materials | Decorating board for construction use | |

Aluminium plastic pipeline | 0.2 | Compound polyethylene plastic | All kinds of pipelines | |

Special specification | Air conditioning foil | 0.105-0.115 | 8011 H22 O | |

Wine banner foil | 0.0105-0.0115 | 8011 O | ||

Foil for medicine | 0.02-0.025 | 8011 H18 |

5. FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is it possible to utilize recycled aluminum to manufacture new items?

- <p>Yes, recycled aluminum can be used to create new products. Aluminum is highly recyclable, and the process of recycling it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains the same properties as new aluminum, making it suitable for a wide range of applications, from packaging to construction materials. The use of recycled aluminum helps reduce waste, conserve resources, and lower environmental impact.</p>

- Q: Can aluminum sheets be used for decorative wall panels?

- Aluminum sheets are indeed suitable for decorative wall panels. As a versatile material, aluminum offers a wide array of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it perfect for both indoor and outdoor applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for limitless design possibilities. Moreover, aluminum can be enhanced in appearance and provided with extra protection against wear and tear through powder-coating or anodizing. Whether it's for residential or commercial spaces, aluminum sheets can impart a modern and stylish touch to any wall, rendering them a highly sought-after choice for decorative wall panels.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- The fourth one.

- Q: How are aluminum sheets different from aluminum plate?

- There are two forms of aluminum metal, namely aluminum sheets and aluminum plates, which primarily differ in terms of thickness. Aluminum sheets are usually thin and flat, with a thickness of less than 6mm. They are commonly utilized in situations where lightweight and flexibility are crucial, such as in the fabrication of aircraft, automobiles, and electronic devices. Conversely, aluminum plates are thicker and heavier than sheets, typically measuring 6mm or more in thickness. Plates are frequently employed in applications that necessitate strength and durability, such as in the assembly of heavy machinery, structural supports, and marine equipment. Despite both sheets and plates being composed of aluminum, their distinctive thicknesses render them suitable for distinct purposes.

- Q: Can aluminum sheets be used for chemical storage containers?

- Certainly, chemical storage containers can utilize aluminum sheets. Renowned for its exceptional resistance to corrosion, aluminum proves itself as a suitable medium for accommodating a diverse array of chemicals. Its lightweight nature, durability, and lack of reactivity with most substances further enhance its appeal for chemical storage purposes, granting it popularity in this field. Moreover, aluminum boasts the ability to be easily shaped and fashioned into an assortment of dimensions and configurations, affording the luxury of customized container designs. Nonetheless, it is crucial to take into account the specific chemical being stored and seek guidance from experts to ensure compatibility and guarantee safety.

- Q: Can aluminum sheets be used in the automotive industry?

- Yes, aluminum sheets can be used in the automotive industry. Aluminum is a lightweight and durable material that offers several advantages in automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, and other structural components. The use of aluminum sheets in automobiles helps to reduce the weight of the vehicle, enhancing fuel efficiency and improving performance. Additionally, aluminum has excellent corrosion resistance properties, which is crucial for vehicles exposed to harsh weather conditions. Furthermore, aluminum sheets can be easily formed, welded, and joined, making them versatile and suitable for various automotive applications. Overall, the automotive industry widely embraces the use of aluminum sheets due to their numerous benefits.

- Q: how to distinguish the physical property of copper sheet from the one of aluminum sheet?

- physical property: copper sheet: golden, heavy, aluminum sheet: white, light.

- Q: Explain the distinctions between aluminum and steel sheets in terms of their properties and applications.

- <p>Aluminum sheets and steel sheets differ in material composition, weight, strength, and applications. Aluminum sheets are lightweight, corrosion-resistant, and have good thermal conductivity, making them ideal for applications requiring light weight and resistance to corrosion. Steel sheets, on the other hand, are heavier, stronger, and more durable, suitable for structural applications where high strength is required. Steel is also magnetic, which aluminum is not, and has a higher melting point. However, steel is more prone to rust compared to aluminum, which requires protective coatings or treatments in many applications.</p>

- Q: Can aluminum sheets be used for structural purposes?

- Yes, aluminum sheets can be used for structural purposes. Aluminum is a lightweight and highly malleable material that can be easily fabricated into various shapes and sizes. It has excellent strength-to-weight ratio, making it suitable for structural applications where weight reduction is a priority. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction for making structural components like panels, beams, and frames. Additionally, aluminum has good corrosion resistance, which further enhances its suitability for structural purposes, especially in outdoor or marine environments. Overall, aluminum sheets offer a reliable and cost-effective solution for structural applications.

- Q: How much do aluminum sheets typically weigh?

- The weight of aluminum sheets ranges from 1.9 to 3.4 grams per square centimeter, and this varies depending on the sheet's thickness and size. Aluminum sheet weight can differ considerably based on its dimensions and gauge. Thinner sheets are typically lighter, while thicker ones tend to be heavier. It is worth mentioning that factors like the alloy utilized and any surface coatings or treatments can also impact the weight of aluminum sheets. Hence, it is recommended to refer to the product specifications or contact the manufacturer for precise weight details.

Send your message to us

Sublimation Embossed Aluminum Metal Sheets 1xxx3xxx5xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords