Aluminum Sheets 1XXX C.C Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets 1xxx C.C Quality Description:

Aluminum sheets 1xxx C.C quality is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum sheets 1xxx C.C quality is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets 1xxx C.C Quality:

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

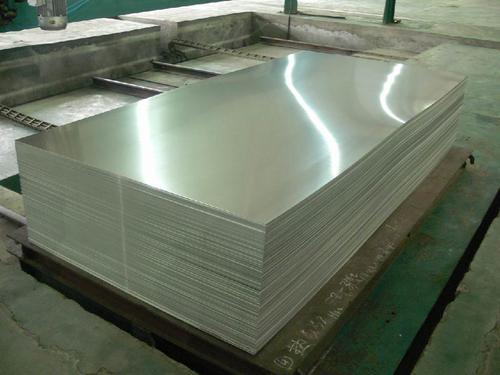

3.Aluminum Sheets 1xxx C.C Quality Images

4.Aluminum Sheets 1xxx C.C Quality Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets 1xxx C.C Quality

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the aluminum sheets 1xxx C.C quality products.

B.When will you deliver the products?

The aluminum aluminum sheets 1xxx C.C quality will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Do 101 aluminum sheets have any specific insulation properties?

- No, 101 aluminum sheets do not have any specific insulation properties.

- Q: For a high school Chemistry course I made soap for a project. Before doing this, thank god, i learned that one should never use an aluminum container to mix the lye (NaOH) and water. Now, I need to know why. I know it eats away at the container but i can't figure out why. It goes against everything I've learned so far. At first i thought it was because Aluminum was, for some strange reason :o, more reactive than Sodium therefore replacing it in the reaction but that turned out not to be true. Does anyone have an idea of why? Thanks

- Under normal circumstances, aluminum does not react with water, as an impermeable protective layer composed of aluminum hydroxide either forms within seconds or is already in place. With the addition of sodium hydroxide, the formation of a protective layer is prevented. With the production of aluminates [ Al(OH)4 ]-, the amphoteric (capable of acting as either an acid or a base) aluminum hydroxide Al(OH)3 goes in solution: 2 Al + 6 H2O -- 2 Al(OH)3 + 3 H2 Al(OH)3 + NaOH -- Na+ + [ Al(OH)4 ]- A layer of aluminum oxide previously formed by passive corrosion is dissolved by the addition of sodium hydroxide. For this reason, the reaction takes place at the beginning relatively slowly: Al2O3 + 2 NaOH + 3 H2O -- 2 Na+ + 2 [ Al(OH)4 ]- The aluminum completely dissolves and the water acts here too as an acid (for an analog, see Experiment 4.4.1). This reaction is used in drain cleaners. They are mostly made out of strong alkalis, to which alumunim or zinc has been added. The alkalis break down organic residues chemically. In addition, the formation of hydrogen leads to a bubbling effect which adds an additional mechanical cleaning mechanism. The big problem here is the formation of hydrogen gas (as well as some heat). The hydrogen gas is flammable, and if it's in a closed container, will explode

- Q: How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

- (the current price of aluminum ingot is about: 15000 yuan / ton, plus board processing fee 2000/ tons, =18000 yuan / ton), the proportion of 2.71*3mm* aluminum plate price 18 yuan / kg, =146.34 yuan / square. 2MM*2.71* price 18 yuan =97.26 yuan / square.

- Q: as for heating coil and aluminum sheet, which one is better for heating?

- Heating coil has a short lifetime, and aluminum sheet for heating can be used for a long time. Stainless steel heating tube is embedded into aluminum sheet for heating, because the heating coil isn’t exposed, it can be used for a long time.

- Q: I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q: Can aluminum sheets be used for roofing?

- Yes, aluminum sheets can be used for roofing. Aluminum is a popular roofing material due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in residential and commercial roofing applications.

- Q: Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- i'm uncertain regardless of the incontrovertible fact that it must be relaxing, are you making thermite? i might guess which you would be able to artwork this out from the atomic weights of each, and taking the valencies under consideration - 2 aluminium atoms for 3 oxygen atoms. 2 iron atoms for 2 oxygen (a million:a million).

- Q: answer them please! i need help. the main question is # 1!!! 2. how many atoms are in one particle of aluminum dichromate?3. how many phosphorus atoms are in one particle of calcium phosphate?4. how many total atoms are in one particle of calcium phosphate?PLEASE!! who ever answers all, ill give them best answer a 5 star ratinggg. please!!! THANK YOU!

- 1) Look at the formula for aluminum nitrate [Al(NO3)3]. The subscript of 3 outside of the parentheses means that you multiply each atom inside the parentheses by 3. Since there is only one nitrogen inside the parentheses, this means that you multiply that by 3. There are a total of 3 nitrogen atoms in each molecule of aluminum nitrate. 2) The formula for aluminum dichromate is Al2(Cr2O7)3. Again, multiply each atom in the parentheses by 3, add them, then add 2 to that number for the aluminum. That's your answer. 3) The formula for calcium phosphate is Ca3(PO4)2. Multiply P by 2. 4) Follow the same steps as in #2, above.

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

Send your message to us

Aluminum Sheets 1XXX C.C Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords