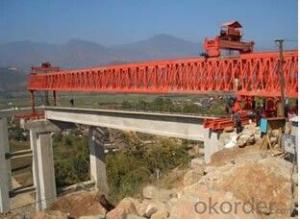

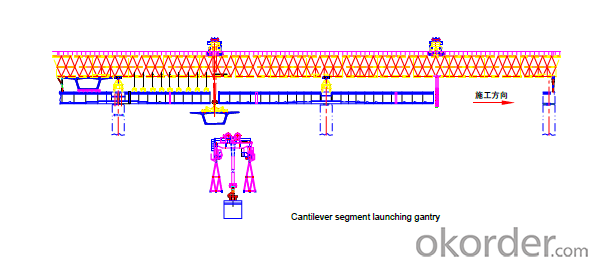

Easy Operation Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cantilever segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: What is the difference between bridge and gantry crane

- Mosaic good (girder girder hoisting a piece also has two tablets, user requirements set) on both sides at the same time on the leg lifting, erect, then workers quickly climbed up, tighten the screws, then the trolley to the main girder structure, just part of the installation on all OK.The main movement in the road: beam yard hanging template, hanging beam, frame beamRailway: beam yard hanging template, hanging beam, frame beamShipyard: hanging welded plateAlso used for cargo handling occasionsWrite bad, please forgive me

- Q: Bridge erecting machine belongs to bridge or gantry crane

- Bridge crane belongs to the bridge crane, which is a large classification, I plant is specialized in the production of bridging machine, Kaifeng Hongda Luqiao equipment factory, the production qualification clearly defined above.

- Q: How much is a bridging machine

- Bridge erection machine is mainly composed of steel structure, lifting, walking and other components, of which the proportion of steel structure

- Q: Safety slogan for bridge erecting machine

- Hello hello!Safety slogan for bridge erecting machine;1, safety first, prevention first!2, scientific development, security development!

- Q: DJ180 bridge machine how to run?

- Two, concrete skew bridge girder erecting machine installation, before, during and after a leg wheel position, left and right wheels to staggered around, the distance can be calculated according to the skew angle, so that the leg wheel can run on the same horizontal track (for details please contact with the manufacturer).Three, bridging machine longitudinal movement to do all the preparatory work, requires a place, not allowed to stop halfway.

- Q: What are the conventional lifting equipment? Bridge erecting machine is a kind of lifting equipment

- A device that is especially large in weight, or a volume of earth objects, such as lifting the house and moving the equipment. In the hoisting machinery category, there is a market called unconventional lifting equipment, generally refers to the general is lifting the weight or volume of the earth is particularly large, objects, such as lifting and moving equipment housing.

- Q: 900 tons bridge machine value how much curiosity just ha ha

- Other models will be expensive, but not more than 13 million.

- Q: Above the highway bridge construction machine, in the case of the erection of the protective scaffolding, bridge construction can be opened to traffic

- Is it possible to allow someone or something else under the bridge machine during the operation.

- Q: What is bridging agent? What is the main purpose?

- 270.388 the content index (%WT) more than 99 of total volatiles (%WT) = 0.10 (c) = 39.02 point white cylindrical crystal properties

- Q: When the bridge frame is equipped with T beam, there are power lines above, we do not have the height of the bridge, so I do not know whether the power line to be removed.

- The problem is not clear, which and where clearance

Send your message to us

Easy Operation Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords