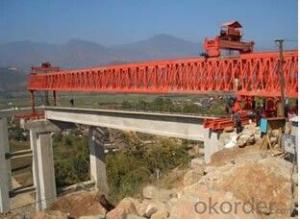

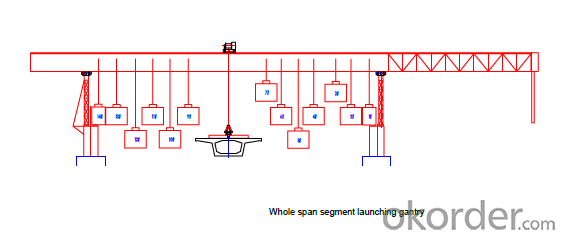

Whole Span Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Whole span segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: What is the difference between bridge and gantry crane

- Mosaic good (girder girder hoisting a piece also has two tablets, user requirements set) on both sides at the same time on the leg lifting, erect, then workers quickly climbed up, tighten the screws, then the trolley to the main girder structure, just part of the installation on all OK.The main movement in the road: beam yard hanging template, hanging beam, frame beamRailway: beam yard hanging template, hanging beam, frame beamShipyard: hanging welded plateAlso used for cargo handling occasionsWrite bad, please forgive me

- Q: Detection and quality standard of bridge erecting machine

- The bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier. Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down. But it is very different from the general sense of the crane. The requirements of the harsh conditions, and the existence of the beam on the line, or called the longitudinal shift. Bridge machine is divided into the erection of highway bridges, conventional railway bridge, passenger dedicated railway bridge, etc..

- Q: Bridge erecting machine belongs to bridge or gantry crane

- Bridge crane belongs to the bridge crane, which is a large classification, I plant is specialized in the production of bridging machine, Kaifeng Hongda Luqiao equipment factory, the production qualification clearly defined above.

- Q: How to weld the wet joint of bridge erecting machine

- No requirement for this specification,According to specification

- Q: When is the installation period, which brand is reliableProfessional name should be crane safety monitoring and management system

- Safety monitor of RJ-180 type bridge machine by a dynamic display of the host (built-in brake control), angle sensor, height sensor, angle sensor, speed sensor, weight sensor, sensor, lateral longitudinal stroke stroke sensor, level sensor, wireless communication module, real-time acquisition and display the running state of the bridging machine.

- Q: Safety slogan for bridge erecting machine

- 8, life is priceless, peace is a blessing!9, to prevent accidents, the first treatment of hidden dangers!10, the development of enterprises, security is guaranteed!11, the safety of everyone arrested, happy 10 million!12, strictly abide by the safety system, strict operating procedures!13, machine frame under strict operation, prohibited to stand!15, safety is the life of the violation is the source of the accident!

- Q: Main components of bridge erecting machine

- 1, armThe machine arm is bearing girder erecting machine, double box girder structure, according to the stress condition of the machine arm and finite element calculation, each box girder design into cross-section form. The full length 66.0m, the box girder is high 3.0m, is divided into six sections; the center distance of the two main girders is 9m, and the high-strength bolt connection is adopted between the segments. After the disintegration of the segment can be transported by road or rail.

- Q: What are the advantages and disadvantages of the overhead bridge erecting machine compared to the lower bridge erecting machine

- There is no good way to deal with the wind when the bridge erecting machine is in the lifting section

- Q: Bridging machine inspection which information and what departments to go? Ah!!!!!!

- They examine the outward appearance of the export machinery and export packaging, after approval, in the customs declaration on the seal, this product can be shipped out.

- Q: When the bridge frame is equipped with T beam, there are power lines above, we do not have the height of the bridge, so I do not know whether the power line to be removed.

- The problem is not clear, which and where clearance

Send your message to us

Whole Span Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords