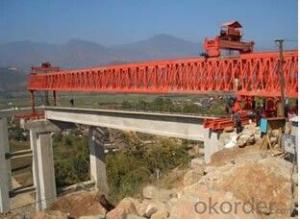

High-efficient Whole Span Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

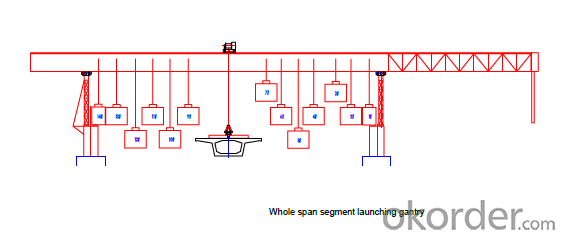

Whole span segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: What is the technical parameter of 30m/100t fixed guide beam of bridge erector?

- Project WJQ50/180~200 WJQ40/150~160 WJQ30/100~120Maximum lifting weight (T) 180150100Adaptive bridge span (m) 35~50 30~40 20~30

- Q: How to weld the wet joint of bridge erecting machine

- No requirement for this specification,According to specification

- Q: Bridge erection of a small box girder of long time

- Generally, that is, from the beam to the beam in place is 20 minutes

- Q: What should be done before the erection of the bridge girder

- But what should be done before the erection of the bridge frame? Here for you to explain! 1, bridge erecting machine at the end of the bridge is ready to assemble the beam, should be placed in the bridge at the vertical track, in order to frame beam; 2, the bridge machine cantilever to the next bridge pier; forward process should ensure the stability of truss. 3, the bridge machine in the back of the four hydraulic cylinder at the same time out, so that the bridge machine in the rear of the car to drive, pull the drive car to change the direction of its movement, auxiliary personnel quickly laying the longitudinal track. The hydraulic cylinder is driven by a hydraulic cylinder.

- Q: What kind of machinery is the bridge? Is the bridge crane or bridge crane? What is the difference between the three?

- And there is walking on the beam, or called the longitudinal displacement. The biggest difference between the bridge erecting machine and the general overhead traveling crane is that it needs to go through the hole itself

- Q: The difference between the bridge erecting machine and machine

- Bridge machine is mainly used for large span bridges, each section is divided into many sections together to large degree. The prefabricated bridge machine section hoisting in place, in a cross together, according to the crane, bridge span, and to select the bridging machine, bridge building machine is mainly used for railway box girder construction, when the segment assembly is completed, but also with the bridge machine horizontal wet joint and tension operation after the period of construction, to be later after the completion of construction, only a downward move across. Bridge machine commonly used 40 meters (inclusive) within the T beam, box girder erection, the end of the frame on the line, it moves down a cross, the latter construction and it does not matter.

- Q: Weight of 120 ton bridging machine

- Using the maximum slope; slope less than 3% cross slope is less than or equal to 3%

- Q: Bridge machine has a sale of the code, used to query the bridge machine related information, is generally how much

- 0086 is the number, arrangement of crane factory sales department the orders of the factory will be mostly single beam double beam gantry crane bridge machine factory production of all types of single beam arranged together another individual plant and some other arrangement of course arrangement of rn: LD16T-22.5M 10120188rn 10120188 number meaning 16T 22.5M span single beam is a contract signed in December 2010 0188. Is the crane factory sales order arrangement number

- Q: Operating rules for bridge erecting machines

- Two, concrete skew bridge girder erecting machine installation, before, during and after a leg wheel position, left and right wheels to staggered around, the distance can be calculated according to the skew angle, so that the leg wheel can run on the same horizontal track (for details please contact with the manufacturer).

- Q: 100 tons of bridge crane can lift 100 tons beam

- No way。 Because it does not include the weight of the bridge.

Send your message to us

High-efficient Whole Span Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords