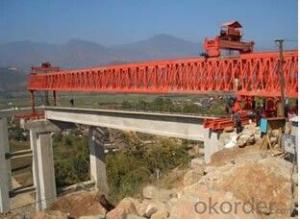

High-end Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

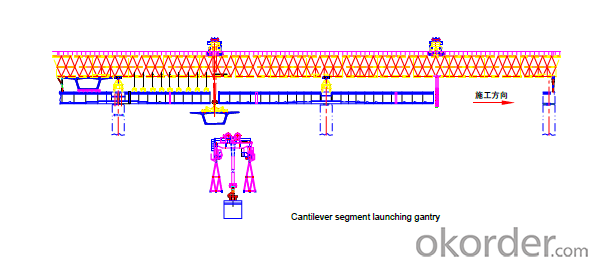

Cantilever segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q: What is the difference between bridge and gantry crane

- Mosaic good (girder girder hoisting a piece also has two tablets, user requirements set) on both sides at the same time on the leg lifting, erect, then workers quickly climbed up, tighten the screws, then the trolley to the main girder structure, just part of the installation on all OK.The main movement in the road: beam yard hanging template, hanging beam, frame beamRailway: beam yard hanging template, hanging beam, frame beamShipyard: hanging welded plateAlso used for cargo handling occasionsWrite bad, please forgive me

- Q: Self-propelled bridge erecting machineMore than 80 tons of self erecting machine price is about how muchKnow the trouble to provide point information!

- The main structure of the hollow box girder, rigid, so the reduction of great magnitude, aspect of stable operation and the operation mechanism can be arbitrary 360 degree turn, orthogonal, can be set up in any direction and angle of skew bridge. Compared with the prior art, the machine has the advantages of light weight, short body lifting ability

- Q: Bridge erection of a small box girder of long time

- It depends on the length of your box girder

- Q: What should be done before the erection of the bridge girder

- The bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier. Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down

- Q: When does the bridge machine not belong to the gantry crane?

- Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down

- Q: Double guide beam bridge machine working principle

- Double island bridge erecting machine name by the two vertical beam, a transverse rod or beam between the two steel frame girder, common triangular truss, also in LCL beam, beam above a crane, following a leg, mobile

- Q: Bridge crane is a bridge crane should be classified as that? Bridging machine

- Bridge crane is a bridge crane should be classified as that? Is it called bridging machine 5Chj201010 | browse 464Recommended 2016-06-25 22:18:20 best answerThe bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier. Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down. But it is very different from the general sense of the crane. The requirements of the harsh conditions, and the existence of the beam on the line, or called the longitudinal shift. Bridge machine is divided into the erection of highway bridges, conventional railway bridge, passenger dedicated railway bridge, etc..

- Q: Operating rules for bridge erecting machines

- The vertical height of the longitudinal running rail of the bridge erecting machine is corresponding to the height requirement, and is stable. Front, middle and rear legs of the horizontal running track requirements, and strictly control the spacing, the three tracks must be parallel.

- Q: How does the bridging machine work?

- If this thing can be explained with the image should be more clear

- Q: What is bridging agent? What is the main purpose?

- Bridging agent formula: [C6H5C (CH3) 2O]2 molecular weight

Send your message to us

High-end Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords