Dry Roasting Equipment---Tunnel Roasting Kiln---The Mobile Rotary Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

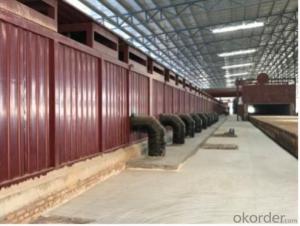

Tunnel roasting kiln can be divided into straight tunnel kiln (with kiln car) and mobile rotary tunnel kiln (without kiln car). Straight tunnel kilns can be further divided into masonry tunnel kilns and prefabricated tunnel kilns in terms of construction methods. The mobile rotary tunnel kiln belongs to the assembled tunnel kiln.

The Mobile Rotary Tunnel Kiln:

(1) Main products: sintered common bricks, porous bricks, hollow bricks

(2) According to the different output, the gauge of mobile rotary tunnel kiln can be divided into the following types:

① the gauge is 7.2 meters, suitable for 150,000-200,000 pieces per day (common bricks)

② the gauge is 8.6 meters, suitable for 200,000-300,000 pieces per day (common bricks)

③ the gauge is 10.8 meters, suitable for daily production of 300,000-400,000 pieces (common bricks)

④ the gauge is 12.98 meters, suitable for daily production of 400,000-500,000 pieces (common bricks)

⑤ the gauge is 16.8 meters, suitable for daily production of 500,000-600,000 pieces (common bricks)

(3) Kiln body structure

Using prefabricated structure, the kiln wall and kiln roof are factory processed into different units and spliced on site. Aluminum silicate refractory fiber is both the working layer and the insulation layer, and different thicknesses and materials are used in different temperature sections. The exterior is composed of steel frame and color steel plate and relates to the transmission mechanism to complete the movement of the kiln body.

(4) The drying and roasting of the mobile rotary tunnel kiln is completed at one time, and the length of the tunnel kiln is more than 160 meters. The diameter of the inner rail of the tunnel is greater than 78 meters, and the diameter of the outer rail of the tunnel is greater than 90 meters.

(5) Firing temperature: 900-1050℃

(6) Firing cycle: 48h

- Q: What is the best drying equipment?

- Through the filter to make hot air purification, and then by the left shunt plate to the layers, so that the average hot air through each layer of dry material.

- Q: The working principle of belt dryer

- Drying process is a hot air flow through the material layer, complete the process of heat and mass transfer, the upper cavity connected by the duct and the fan inlet. Most of the gas circulation, part of the lower temperature of the larger moisture content of the gas as exhaust gas through the drainage tube, regulating valve, drain fan discharge. The next cycle of the unit, the fan out of the wind into the upper cavity, down through the heat exchanger heating, through the material layer into the lower chamber, the lower chamber by the side duct and return air duct connected to the fan, most of the gas circulation, Part of the discharge. Up and down the cycle unit according to user needs can be flexible equipment, the number of units can also be selected according to need.

- Q: What are the basic types of common drying equipment?

- (4) hollow paddle dryer (leaf dryer) hollow paddle dry dryer, also known as leaf dryer, mainly by the jacket with the W-shaped shell and two hollow blade shaft and transmission components. A hollow blade is arranged on the shaft and a rotary joint with a heat medium inlet is provided at the shaft end. The heat required to dry the moisture is conducted to the material by the inner wall of the W-shaped groove with the jacket and the hollow leaf wall.

- Q: What are the common types of dryers?

- The tank flows into the chute of the drum dryer, and the drying drum is rotated at the specified speed by the drive.

- Q: What are the common drying methods?

- heating and drying method

- Q: How to solve the dryer a series of failures

- On the other hand, after the dryer was replaced, the dew point immediately peaked, indicating that the dryer was not adequately cooled before it was so well that it could not adsorb moisture well and that the dew point of the dryer would be reduced to normal after cooling. If the dryer is cooled properly, it will cause the temperature to peak. The sudden change in temperature will reduce the drying ability of the desiccant to heat-sensitive materials such as ionomers, amorphous polyesters and certain nylon grades.

- Q: How to choose the right drying equipment and drying technology

- In determining the drying process, it is of vital importance to identify the drying properties of the material.

- Q: The development prospects of the dryer

- performance, the use of compact heat exchangers, such as plate fin heat exchangers, is promising. (The current difficulties may still be in terms of price). Promotion of the use of green ring-type refrigerant R134a, including cold and dry machines, including all the direction of development of refrigeration equipment, technically there is no insurmountable obstacles. But this is a great social engineering, an industry, a separate action of a business in addition to some commercial publicity significance, the overall goal of the macro is not much practical effect. In the final analysis, this is a government action, the need for the introduction of policies by the state to define a unified time limit.

- Q: What are the characteristics of the drum dryer?

- According to the dry material is heated, the current rotary drum dryer can be divided into five types, that is, direct Heating dryer, indirect heating dryer, compound heating dryer, steam calcining dryer, spray granulation drying machine.

- Q: What is a combination of drying equipment?

- Combination drying equipment is a combination of two or more dry forms, the main material, mainly in series, that is, when the material has been through the drying equipment, two or more drying equipment, combined dry mainly to meet a The need for a drying process.

Send your message to us

Dry Roasting Equipment---Tunnel Roasting Kiln---The Mobile Rotary Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.