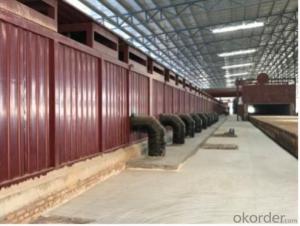

tube dryer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

tube dryer specifications:

reasonable structure

high efficiency

low energy consumption

convenient transportation

Tube Dryer is formed by rotary body, lifting blade, driving device, supporting device and sealing ring. It can be used for drying many kinds of materials and with convenient and reliable operation; therefore, it has been widely used. The Rotary Dryer is used for drying materials with humidity or granularityin the industries of mineral dressing, building material, metallurgy and chemical.

Dryer main application:

The indirect heat transfer dryer made by our company can be used in building materials, metallurgy, chemical industry, cement plant for drying of limestone slag, coal powder, slag, clay stone.

Dryer usage:

This series drier is used for drying materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy and chemical. Rotating dryer can be used for drying many kinds of materials and with convenient and reliable operation; therefore, it has been widely used.

Dryer features:

Widely used in drying different materials!

reasonable structure,high efficiency

low energy consumption

Specifications of Drier

Specifications (m) | Diameter of rotary body | Length of rotary body | Angle of slope | Weight | Inlet temperature () | Capacity |

GZφ600×6000 | φ600 | 6 | 3 | 2.9 | ≤700 | 0.5-1.5 |

GZφ800×8000 | φ800 | 8 | 5 | 3.5 | ≤700 | 0.8-2.0 |

GZφ1000×9000 | φ1000 | 9 | 5 | 5.2 | ≤700 | 0.8-2.5 |

GZφ1000×10000 | φ1100 | 10 | 5-3 | 5.6 | ≤700 | 1.0-3.5 |

GZφ1200×10000 | φ1200 | 10 | 3-5 | 14.04 | ≤700 | 1.8-5 |

GZφ1200×12000 | φ1200 | 12 | 3-5 | 14.8 | ≤700 | 2-6 |

GZφ1500×12000 | φ1500 | 12 | 3-5 | 17.76 | ≤800 | 3.3-7.5 |

GZφ1800×14000 | φ1800 | 14 | 3-5 | 29 | ≤800 | 5-9 |

GZφ2200×12000 | φ2200 | 12 | 3-5 | 33 | ≤700 | 6-12 |

GZφ2200×18000 | φ2200 | 18 | 3-5 | 53.3 | ≤800 | 10-15 |

GZφ2200×20000 | φ2200 | 20 | 3-5 | 56 | ≤800 | 15-25 |

GZφ3000×20000 | Φ3000 | 20 | 3-5 | 78 | ≤800 | 25 |

GZφ3000×25000 | Φ3000 | 25 | 3-5 | 104.9 | ≤800 | 32-36 |

- Q: What is the best drying equipment?

- In order to overcome the above shortcomings. I plant in accordance with foreign advanced technology design and development through the flow box-type dryer, the working principle shown in Figure:

- Q: The working principle of belt dryer

- Drying process is a hot air flow through the material layer, complete the process of heat and mass transfer, the upper cavity connected by the duct and the fan inlet. Most of the gas circulation, part of the lower temperature of the larger moisture content of the gas as exhaust gas through the drainage tube, regulating valve, drain fan discharge. The next cycle of the unit, the fan out of the wind into the upper cavity, down through the heat exchanger heating, through the material layer into the lower chamber, the lower chamber by the side duct and return air duct connected to the fan, most of the gas circulation, Part of the discharge. Up and down the cycle unit according to user needs can be flexible equipment, the number of units can also be selected according to need.

- Q: What are the basic types of common drying equipment?

- (3) drum scraper dryer drum scraper dryer is through the rotation of the cylinder, heat conduction way, will be attached to the outer wall of the cylinder liquid material or ribbon material, a dry continuous operation of equipment The The material to be dried is passed from the upper tank into the receptacle of the drum dryer. The drying drum is driven at the specified speed by the drive.

- Q: What are the common types of dryers?

- The belt dryer consists of a number of individual unit segments, each of which includes a circulating fan, a heating device, a separate or common fresh air extraction system and an exhaust gas extraction system. The amount of drying medium, temperature, humidity and exhaust cycle

- Q: What are the common drying methods?

- Drying method Drying is the process of removing moisture from various materials. Various materials can be solid, liquid or gas, solid and can be divided into large pieces of material, fiber material, pellets, fine powder and so on, Is the moisture in the material, it can be other solvents. In this water for the object. Drying equipment, there are three ways to dry: (1) mechanical dehydration

- Q: How to solve the dryer a series of failures

- The moisture absorption capacity of the dryer is limited, so the moisture it adsorbs must be removed by regeneration. The process is: when the ambient air is inhaled, through a filter into the blower, and then be sent to a group of heaters. The heated air passes through the machine. When the temperature of the dryer rises, the adsorbed moisture is released. When the hot air to absorb water vapor to saturation, it was discharged into the atmosphere. The high temperature regenerative dryer must be cooled before returning to the dry loop to restore the moisture absorption function of the dryer.

- Q: How to choose the right drying equipment and drying technology

- In the drying process of materials, different materials are not the same characteristics, drying requirements are not the same, drying methods are also different, how to choose the right drying equipment and it?

- Q: What are the types of drying equipment?

- According to the operating pressure, the dryer is divided into two types of atmospheric pressure dryer and vacuum dryer. Microwave flour sterilization drying equipment can reduce the moisture partial pressure of the space and accelerate the drying process, and can reduce the wet boiling point and material Drying temperature, steam is not easy to leak, so the vacuum dryer for dry heat-sensitive, easy oxidation, explosive and toxic materials and wet steam needs to be recycled occasions.

- Q: The development prospects of the dryer

- As a compressed air post-processing purification equipment, cold and dry control system will follow the host control technology and continuous improvement. Frequency control, online dew point measurement and control, operating conditions, real-time display and record preservation and so there is a lot of things to do.

- Q: What are the characteristics of the drum dryer?

- direct heating type Rotary drum dryer This kind of dryer is directly connected with the dry material, mainly by convection heat transfer, the most widely used.It is divided into conventional direct heating rotary drum dryer, Rotary drum dryer and ventilated tube rotary drum dryer

Send your message to us

tube dryer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords