Dry Roasting Equipment---Tunnel Dryer---The Once Setting Tunnel Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg/m²

- Supply Capability:

- 50 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

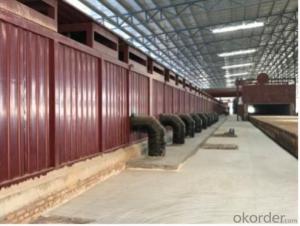

Both the once setting tunnel dryer and the roasting kiln carrying equipment are kiln cars. The section of the dryer is the same as roasting kiln.

The structure of the dryer is a brick-concrete. The side walls are composed of red brickwork and reinforced concrete structural columns. The roof is cast-in-place reinforced concrete, and aerated concrete brickworks are used for thermal insulation.

The drying medium is generally provided by the waste heat and flue heat of the roasting kiln. The dryer is equipped with a hot air supply system, a moisture exhaust system and a temperature and humidity monitoring system. By monitoring and adjusting the system, the supply air temperature and air volume can be controlled to ensure the drying quality of the bricks.

- Q: What is the best drying equipment?

- In the traditional horizontal fan-type dryer, the air flow only in the material surface flow, the drawback is the low heat transfer coefficient, poor heat utilization, material drying time is long.

- Q: What are the common types of dryers?

- The tank flows into the chute of the drum dryer, and the drying drum is rotated at the specified speed by the drive.

- Q: What are the common drying methods?

- heating and drying method

- Q: How to solve the dryer a series of failures

- If the dew point reading is normal after the dry machine is replaced, the dew point rises rapidly after the end of the drying cycle of the dryer, indicating that the ambient air may enter the closed gas path, causing the dryer to absorb prematurely. Another possibility is that the dryer is not completely regenerated or contaminated. If the dew point reading and reflow air dew point readings are close, it indicates that the regenerative gas path is completely failing or the desiccant is seriously polluted.

- Q: How to choose the right drying equipment and drying technology

- Hygroscopic materials can absorb moisture from the surrounding environment, non-hygroscopic materials can not absorb moisture from the environment.

- Q: What are the types of drying equipment?

- he equipment used for the drying operation. Many types. According to the operating pressure can be divided into atmospheric pressure and pressure (vacuum dryer also known as vacuum dryer). According to the operation method can be divided into intermittent and continuous. According to the drying medium can be divided into air, flue gas or other drying medium. According to the movement (material movement and drying medium flow) can be divided into parallel, countercurrent and cross flow.

- Q: The development prospects of the dryer

- As a compressed air post-processing purification equipment, cold and dry control system will follow the host control technology and continuous improvement. Frequency control, online dew point measurement and control, operating conditions, real-time display and record preservation and so there is a lot of things to do.

- Q: Frozen sublimation drying equipment which consists of several systems

- the vacuum system: by the freeze-drying room, condenser, vacuum valves and pipes, vacuum equipment and vacuum instrument composition, the current vacuum equipment is extremely combination of three: the Roots pump, cryogenic condenser, and multi-stage steam ejector, which , Multi-stage steam ejector structure is simple, no mechanical power, easy maintenance, low failure rate, the material requirements are not high, usually need to set 4-5 level.

- Q: What are the characteristics of the drum dryer?

- conventional direct heating rotary drum dryer conventional direct heating rotary drum dryer in the dry material and hot air Direct contact with the way of convection heat drying in accordance with the direction of flow between the hot air and material, divided into parallel and countercurrent.

- Q: What is a combination of drying equipment?

- As we all know, each dryer there are some shortcomings, through the same or two or more models in series, using their own advantages, often play a single device can not achieve the purpose.

Send your message to us

Dry Roasting Equipment---Tunnel Dryer---The Once Setting Tunnel Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg/m²

- Supply Capability:

- 50 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.