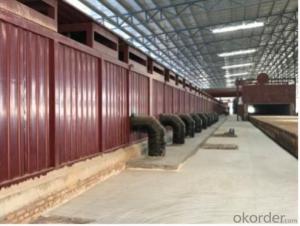

Dry Roasting Equipment---Chain Plate Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

chain plate dryer(When the moisture content of the raw material is high, the secondary dryer equipment is used)

Number | Name | Unit | Parameter | Remark |

1 | Device Name | Chain Plate Dryer | ||

2 | Dry Variety | Hollow bricks and hollow blocks, porous bricks and porous blocks, common bricks, etc. | ||

3 | Dry Qualified Product Rate | % | 99 | |

4 | Daily Output (Common bricks) | ten thousand | 30-40 | |

5 | Dryer Structure | Detachable combination of steel structure | ||

6 | Delivery Method | Chain Conveyor | ||

7 | Chain Layers | Floor | 2-3 | |

8 | Dryer Length | m | 100—150 | Length can vary |

9 | Dryer Height | mm | 360—460 | Determined by Product |

10 | Dryer Heat Source | Tunnel Kiln Waste Heat(cooling product heat, smoke heat separation heat) | ||

11 | Heat Source into The Dryer Temperature | ℃ | <150 | |

12 | Dryer Exhaust Gas Temperature | ℃ | <45 | |

13 | Drying Cycle | Hour | 2~10 | |

14 | dryer control | Electronic computer program control | Remote monitoring possible | |

- Q: What is the best drying equipment?

- Through the filter to make hot air purification, and then by the left shunt plate to the layers, so that the average hot air through each layer of dry material.

- Q: The working principle of belt dryer

- Drying process is a hot air flow through the material layer, complete the process of heat and mass transfer, the upper cavity connected by the duct and the fan inlet. Most of the gas circulation, part of the lower temperature of the larger moisture content of the gas as exhaust gas through the drainage tube, regulating valve, drain fan discharge. The next cycle of the unit, the fan out of the wind into the upper cavity, down through the heat exchanger heating, through the material layer into the lower chamber, the lower chamber by the side duct and return air duct connected to the fan, most of the gas circulation, Part of the discharge. Up and down the cycle unit according to user needs can be flexible equipment, the number of units can also be selected according to need.

- Q: What are the basic types of common drying equipment?

- (4) hollow paddle dryer (leaf dryer) hollow paddle dry dryer, also known as leaf dryer, mainly by the jacket with the W-shaped shell and two hollow blade shaft and transmission components. A hollow blade is arranged on the shaft and a rotary joint with a heat medium inlet is provided at the shaft end. The heat required to dry the moisture is conducted to the material by the inner wall of the W-shaped groove with the jacket and the hollow leaf wall.

- Q: What are the common drying methods?

- Drying method Drying is the process of removing moisture from various materials. Various materials can be solid, liquid or gas, solid and can be divided into large pieces of material, fiber material, pellets, fine powder and so on, Is the moisture in the material, it can be other solvents. In this water for the object. Drying equipment, there are three ways to dry: (1) mechanical dehydration

- Q: How to solve the dryer a series of failures

- If the dew point reading is normal after the dry machine is replaced, the dew point rises rapidly after the end of the drying cycle of the dryer, indicating that the ambient air may enter the closed gas path, causing the dryer to absorb prematurely. Another possibility is that the dryer is not completely regenerated or contaminated. If the dew point reading and reflow air dew point readings are close, it indicates that the regenerative gas path is completely failing or the desiccant is seriously polluted.

- Q: How to choose the right drying equipment and drying technology

- Materials can be divided into two kinds of hygroscopic and non-hygroscopic.

- Q: What are the types of drying equipment?

- he equipment used for the drying operation. Many types. According to the operating pressure can be divided into atmospheric pressure and pressure (vacuum dryer also known as vacuum dryer). According to the operation method can be divided into intermittent and continuous. According to the drying medium can be divided into air, flue gas or other drying medium. According to the movement (material movement and drying medium flow) can be divided into parallel, countercurrent and cross flow.

- Q: The development prospects of the dryer

- As a compressed air post-processing purification equipment, cold and dry control system will follow the host control technology and continuous improvement. Frequency control, online dew point measurement and control, operating conditions, real-time display and record preservation and so there is a lot of things to do.

- Q: What are the characteristics of the drum dryer?

- According to the dry material is heated, the current rotary drum dryer can be divided into five types, that is, direct Heating dryer, indirect heating dryer, compound heating dryer, steam calcining dryer, spray granulation drying machine.

- Q: What is a combination of drying equipment?

- Recently, a combination of different drying methods and different drying principles has been widely used, and a drying device capable of exerting their own advantages and making up their respective shortcomings.

Send your message to us

Dry Roasting Equipment---Chain Plate Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.