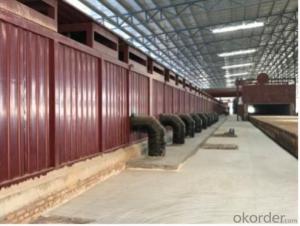

Dry Roasting Equipment---Tunnel Dryer---The Secondary Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg/m²

- Supply Capability:

- 50 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The carrier equipment of the green brick in the secondary dryer is a drying car. The bricks are stacked on the drying car by the racking system. After drying, the drying car is unloaded by the lowering system, and then the bricks are stacked on the kiln car by the racking system. This operation adopts a single layer drying method, which is suitable for raw materials with high moisture content, because each green brick is fully dried, and the drying efficiency is high.

The drying medium is generally provided by the waste heat of the roasting kiln and is supplemented by the burner when the heat is insufficient. The drying room is equipped with a hot air supply system, a moisture exhaust system and a temperature and humidity monitoring system. By monitoring and adjusting the system, the supply air temperature and air volume can be controlled to ensure the drying quality of the bricks.

The structure of the secondary dryer is a multi-channel brick-concrete structure or a multi-channel frame structure without partition walls to adapt to different drying requirements.

- Q: What is the best drying equipment?

- Through the filter to make hot air purification, and then by the left shunt plate to the layers, so that the average hot air through each layer of dry material.

- Q: The working principle of belt dryer

- For the material temperature does not exceed 60oC requirements, can be used about 80oC dry gas. Multi-stage combination can better play the performance of belt dryer, and dry more uniform.

- Q: What are the common types of dryers?

- The amount of operating parameters, can be independently controlled, so as to ensure the reliability of the work with dry and operating conditions optimization.

- Q: What are the common drying methods?

- In the actual production process, for high-humidity materials are generally as much as possible first with mechanical dehydration method to remove a large number of free water, and then take other drying methods for drying.

- Q: How to solve the dryer a series of failures

- On the other hand, after the dryer was replaced, the dew point immediately peaked, indicating that the dryer was not adequately cooled before it was so well that it could not adsorb moisture well and that the dew point of the dryer would be reduced to normal after cooling. If the dryer is cooled properly, it will cause the temperature to peak. The sudden change in temperature will reduce the drying ability of the desiccant to heat-sensitive materials such as ionomers, amorphous polyesters and certain nylon grades.

- Q: How to choose the right drying equipment and drying technology

- Materials can be divided into two kinds of hygroscopic and non-hygroscopic.

- Q: What are the types of drying equipment?

- According to the operating pressure, the dryer is divided into two types of atmospheric pressure dryer and vacuum dryer. Microwave flour sterilization drying equipment can reduce the moisture partial pressure of the space and accelerate the drying process, and can reduce the wet boiling point and material Drying temperature, steam is not easy to leak, so the vacuum dryer for dry heat-sensitive, easy oxidation, explosive and toxic materials and wet steam needs to be recycled occasions.

- Q: The development prospects of the dryer

- Compared with the adsorption dryer, the cold and dry machine is relatively energy efficient in its applicable field. But the cold and dry machine in the small load operation also exists "big horse car" energy waste phenomenon. People want the cold and dry power consumption can follow the load changes and adjust themselves to achieve the best energy saving effect,

- Q: Frozen sublimation drying equipment which consists of several systems

- the control system: the control system consists of a variety of monitoring the original, an umbrella device, instrumentation and other components, a higher degree of automation control system can be set by the freeze-drying process automatically operate, while the vacuum, heating plate temperature and cooling System monitoring and alarm, record all kinds of data.

- Q: What are the characteristics of the drum dryer?

- The current resistance is small, you can use it to dry the granular material.Currently the development of domestic drum dryer has been in the world advanced level, from the practical sense, the drying device in addition to improving the shape of the internal device design, gas transport regulation and other details Factors, in other areas no longer have the technical leap and innovation, the current technology has been able to meet the general needs.

Send your message to us

Dry Roasting Equipment---Tunnel Dryer---The Secondary Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg/m²

- Supply Capability:

- 50 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.