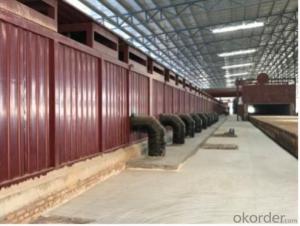

Dry Roasting Equipment---Tunnel Roasting Kiln---Straight Tunnel Kiln---Masonry Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tunnel roasting kiln can be divided into straight tunnel kiln (with kiln car) and mobile rotary tunnel kiln (without kiln car). Straight tunnel kilns can be further divided into masonry tunnel kilns and prefabricated tunnel kilns in terms of construction methods. The mobile rotary tunnel kiln belongs to the assembled tunnel kiln.

Straight Tunnel Kiln:

(1) Main products: sintered bricks, common bricks, porous bricks, hollow bricks/blocks, roof tiles, hollow wall panels.

(2) According to the different output, the inner width of the tunnel kiln is divided into the following types:

① the inner width is 3.6 and 3.7 meters, suitable for daily output of 150,000-200,000 blocks, and annual output of 50-66 million (common bricks)

② the inner width is 4.6 and 4.8 meters, suitable for daily output of 210,000-250,000 blocks, and annual output of 69-82 million (common bricks)

③ the inner width is 5.4 and 5.6 meters, suitable for daily production of 260,000-300,000 pieces, and annual output of 85-100 million (common bricks)

④ the inner width is 6.9 and 7.2 meters, suitable for daily output of 310,000-400,000 blocks, and annual output of 102-132 million (common bricks)

⑤ the inner width is 9.2 and 9.4 meters, suitable for daily output of 600,000-620,000 pieces, and annual output of 165-200 million (common bricks)

(3) Kiln Body Structure

Masonry Tunnel Kiln:

The kiln wall is a composite wall, and the innermost layer is the working layer in contact with the high temperature. It is usually built with refractory materials (common bricks can be sintered below 600°C). The materials, grades and specifications of the refractory materials used are determined according to the firing temperature of the kiln. The middle layer is the thermal insulation layer, which is composed of various lightweight thermal insulation materials. The selected lightweight thermal insulation materials should not only provide thermal insulation, but also maintain long-term safe use without damage. The outermost layer is a load-bearing protective layer, which is multi-purpose sintering. This layer is mostly built with sintered common bricks and porous bricks to protect the lightweight thermal insulation material from damage and to bear the load of the kiln roof and the transverse thrust of the vault.

The roof of the kiln is a composite kiln item, which is hoisted on site. Commonly used kiln roof structures are refractory fiber module + refractory fiber blanket + sealed castable + steel beam; clay refractory slab + high alumina hanger + refractory fiber blanket + sealed castable + steel beam; light mullite Brick + high-aluminum hanging column + refractory fiber blanket + sealing castable + steel beam.

(4) Firing temperature: 950-1050℃

(5) Firing cycle: 26-40h

(6) Length of tunnel kiln: 110-170m

(7) Length and size of kiln car: It is determined according to the size of the billet stack and the internal and external combustion method. The length and size of the commonly used kiln car are: 3600mm, 3900mm, 4100mm, 4200mm, 4350mm, 4800mm, etc.

(8) Firing method: all internal combustion roasting; all external combustion roasting; combined internal and external combustion roasting.

(9) The roasting kiln is often equipped with a smoke exhaust system, a combustion system, a waste heat system, a backburning system, a cooling system, and a bottom pressure balance system. Each system consists of fans, pipes and regulating valves. The kiln has a large section, high output, small temperature difference between sections, and good thermal insulation performance. Computer automatic monitoring and control system to ensure the stability of thermal parameters and roasting quality

- Q: What is the best drying equipment?

- In the traditional horizontal fan-type dryer, the air flow only in the material surface flow, the drawback is the low heat transfer coefficient, poor heat utilization, material drying time is long.

- Q: The working principle of belt dryer

- The material in the hopper is spread evenly by the feeder, and the mesh belt is generally made of 12-60 mesh stainless steel wire and is moved by the transmission in the dryer. The dryer consists of several units, each unit of hot air independent cycle, in which part of the exhaust by the special discharge fan 4 discharge, each unit discharge exhaust gas by the control valve control. In the upper circulation unit, the wind coming out of the circulating fan 5 enters the lower chamber of the unit by the side air duct, the air flow is heated upwardly through the heater 7, and the dispenser 6 is dispensed to form a jet stream into the mesh belt, Cavity.

- Q: What are the basic types of common drying equipment?

- (2) Belt Dryer Belt Dryer consists of several independent unit segments. Each unit section includes a circulating fan, a heating device, a separate or common fresh air extraction system and an exhaust gas extraction system. On the drying medium quantity, temperature, humidity and exhaust gas circulation operating parameters, can be independently controlled, so as to ensure the reliability of working with dry and operating conditions optimization.

- Q: What are the common types of dryers?

- The belt dryer consists of a number of individual unit segments, each of which includes a circulating fan, a heating device, a separate or common fresh air extraction system and an exhaust gas extraction system. The amount of drying medium, temperature, humidity and exhaust cycle

- Q: What are the common drying methods?

- In the actual production process, for high-humidity materials are generally as much as possible first with mechanical dehydration method to remove a large number of free water, and then take other drying methods for drying.

- Q: How to solve the dryer a series of failures

- On the other hand, after the dryer was replaced, the dew point immediately peaked, indicating that the dryer was not adequately cooled before it was so well that it could not adsorb moisture well and that the dew point of the dryer would be reduced to normal after cooling. If the dryer is cooled properly, it will cause the temperature to peak. The sudden change in temperature will reduce the drying ability of the desiccant to heat-sensitive materials such as ionomers, amorphous polyesters and certain nylon grades.

- Q: What are the types of drying equipment?

- he equipment used for the drying operation. Many types. According to the operating pressure can be divided into atmospheric pressure and pressure (vacuum dryer also known as vacuum dryer). According to the operation method can be divided into intermittent and continuous. According to the drying medium can be divided into air, flue gas or other drying medium. According to the movement (material movement and drying medium flow) can be divided into parallel, countercurrent and cross flow.

- Q: Frozen sublimation drying equipment which consists of several systems

- the heating system: for heating the freeze-drying room shelf, to promote the material within the ice sublimation, direct and indirect heating in two ways, direct heating is the direct heating in the box inside the shelf, indirect heating is the use of electricity Or other heat source heat transfer medium, and then pass it into the shelf.

- Q: What are the characteristics of the drum dryer?

- According to the dry material is heated, the current rotary drum dryer can be divided into five types, that is, direct Heating dryer, indirect heating dryer, compound heating dryer, steam calcining dryer, spray granulation drying machine.

- Q: What is a combination of drying equipment?

- Combination drying equipment is a combination of two or more dry forms, the main material, mainly in series, that is, when the material has been through the drying equipment, two or more drying equipment, combined dry mainly to meet a The need for a drying process.

Send your message to us

Dry Roasting Equipment---Tunnel Roasting Kiln---Straight Tunnel Kiln---Masonry Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.