Coke Oven Equipment > Heat-Recovery Coke Oven Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

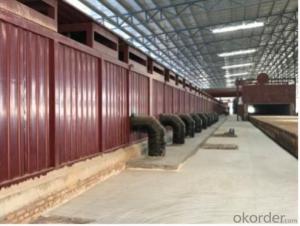

TYHI designs and manufactures heat-recovery coke oven machinery. We own a number of patents and we have won the Second Prize for Science & Technology Development in Shanxi Province.

Our heat-recovery coke oven machinery can be used for cake stamping, coal charging and pushing. Our hydraulic stamping station is equipped with a MTS hydro-cylinder to enhance precision and control. By adopting advanced static-pressure technology, it makes coal cakes flatter, the burn spoilage rate lower and stamping time shorter. Our charging-pushing cars use coal trays to transfer coal which solves the problem of charging fall, additionally it cuts costs and reduces the repair rate. Our receiving-quenching cars have end-joint receiving which prevents dust pollution. Moreover, our separated dragging cars and receiving cars reduce heat effect to electric and hydraulic equipment.

Technical parameter | ||

1 | Chamber length (cold/hot) in mm | 13340/13530 |

2 | Chamber average width in mm | 3596 |

3 | Chamber height (cold) in mm | 2758 |

4 | Coal capacity per oven (wet) | ~50t |

5 | Coke production per oven (t) | ~37t |

Our main products include lifting equipment, forging equipment, rolling equipment, excavation equipment, coke oven equipment, coal chemical equipment, wind power generating equipment, oil film bearings for rolling mills, gear drive equipment, train wheels and axles, forgings and castings and project contracting.

Our key products include our 1200t EOT crane, our 500t ladle crane, our 75m³ shovel for mining, our Φ180mm continuous rolling production line, our 110 MN aluminum alloy extrusion press and our 7m top charging coke oven equipment.

TYHI’s products are widely used in the metallurgical, mining, energy, transportation, aerospace, chemical, rail, ship building, environmental protection and various other industries. Many products designed and manufactured by TYHI have filled gaps in the domestic market. Furthermore, we have created 360 nationally and internationally recognized products which have been exported to approximately forty countries and regions.

TYHI is now delving further into the development of the rail, engineering machinery, new energy, and maritime equipment fields. We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q: CNC lathe price

- One hundred thousand or less, basically can only choose the domestic turret lathe.

- Q: What is the meaning of R in the data lathe?

- W: the amount of feed (exit) required to exit or insert at the original X-axis coordinate point;

- Q: Machine operating procedures

- The operator must pass the exam and hold the "equipment operation card" of the machine to operate the machine.

- Q: What is the risk of CNC lathes

- 2, iron dust dust pollution, processing parts will produce some debris;

- Q: Which machine is the leading machine

- 600806 Kunming machine, to complete sets of heavy-duty CNC machine tool dominate the domestic.

- Q: The difference between CNC machine tools and ordinary machine tools

- While the CNC machine tools are not complicated by the variable speed mechanism because its motor is computer-controlled stepless.

- Q: Who can tell me the difference between instrument lathe and CNC lathe

- X, Z axis of the servo motor to control the lathe feed movement of the action sequence, the amount of movement and feed speed, coupled with the spindle speed steering, and automatic tool change system, enabling the processing of different shapes of different shaft

- Q: Shenyang machine i5 machine only how?

- Shenyang Machine Tool this year launched a new product, said that the new product, in fact, is the original ETC series of CNC cars, the difference is not in the configuration of other systems, only with Shenyang machine machine I5, stability, how to talk about it from the configuration point of view should be good,

- Q: What is the advantage of other CNC machine tools compared to other equipment?

- low labor costs, to adapt to different parts of the processing capacity.

- Q: What lathes are lathes?

- Is a professional sales agents at home and abroad in large and medium-sized famous machine equipment and a variety of machine tool equipment installation, maintenance, CNC transformation, a variety of CNC machine tools for the design and manufacture

Send your message to us

Coke Oven Equipment > Heat-Recovery Coke Oven Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches