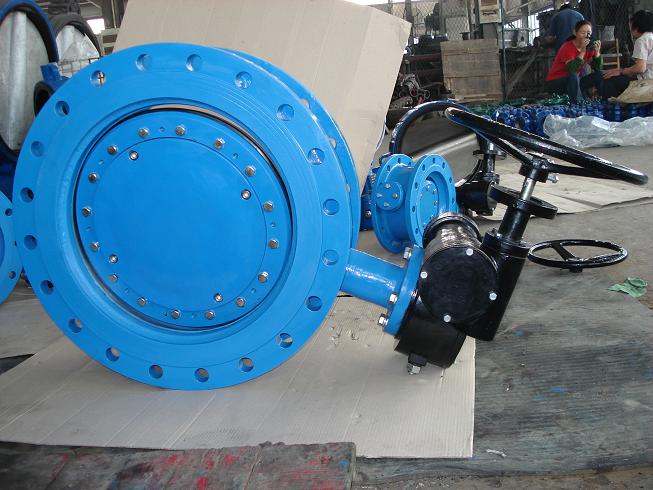

Double flanged Metal Seal eccentric butterfly valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Double flanged Double Eccentric Butterfly Valve

PN10/16/25

DN100 ~ DN2000

Technical Specifications

- Design and manufacture: EN593, EN1074-1 and 2

- Face to face dimension: EN558-1 Series 14 (DIN3202 F4)

EN558-1 Series 13 (BS5163)

- Flange dimensions and drillling: EN1092-2 PN10/16/25

- Size range: DN100 - DN2000

- Max. working pressure: 1.0/1.6/2.5 MPa

- Inspection test: EN12266

- Working temperature: -15°C to +80°C

- Suitable medium: water

Main Fetures

- Double eccentric disc reduces seal wear and torque

- Body seat ring is welded directly on the body

- Bi-directional flow and low head loss

- Disc sealing ring to be replaceable on pipeline without dismantling the valve

- Body and disc inside and outside epoxy powder coated (min. 250 microns)

- Opening and closing indicators are provided

- Coupling flange for electric actuator in compliance with ISO5211

- Gearbox and electric actuator operation available

Main Parts and Materials

Body and disc: ductile iron EN GJS500-7/400-15

Shafts: stainless steel AISI 420

Body seat ring: stainless steel AISI 304

Disc sealing ring: EPDM or NBR

Retaining ring: stainless steel or ductile iron

Shaft bearing: Du bushes (self lubricating bushes)

- Q: I don't have one single water shutoff valve in my house that will shut anything off completely. It looks fairly easy to repack them, and I have the tools, and there are instructions all over the internet. The question I have for the experienced among you is what packing material do I use? I have heard graphite thread and teflon tape and even joint compound.Is one better than the other? Easier to use?Also, if there are any pitfalls I should know about before I undertake this, please advise.Thanks in advance!

- Well if you talking about the water shutoff valves under sinks then you need to first shut off the water comming into the house at the main shutoff valve near the street , Or at a line comming into the house that connects up to the valve you are trying to fix or you may take a slight bath while trying to fix the valve that wont shutoff. Then Go to the shutoff valve you want to repair in that line where you shut the water off at and unsrew the handle at the base of the handle shaft using two wrenchs to hold both the nut on the shaft while using the other to hold the shutoff valve .this will prevent twisting the valve right off the connecting lines. Most of the time you will find it has a rubber gromet attached by a screw to the handle shaft.this is what you need to replace with a new rubber gromet which you can get in an assortment box at wal mart or homedepot or lowes for a low price. If you are using teflon thread or jointcompound you are repairing a Pipe joint leak where water is leaking externally of the pipe,not a shutoff valve leak .

- Q: non-return valves

- ..?..non-return valves..? I will assume that your 'non-return valves', are what is also known as check valves. Check valves allows flow in one direction only. These are used wherever you need to prevent backflow into the system, or to maintain a charged circuit with fluid, until you choose to unload(depressurize ) it. Now, why are they used in discharged lines of salt water, basically to prevent backflow....reason not known, here , requires usage info.

- Q: i wanted to know what is the actual difference between check valve (non return valve) and globe valve?

- Nrv Check Valve

- Q: My car hesitates on the highway 55 m/h and up after about 20 minutes of highway driving, I unplugged the EGR valve to see if it still hesitates, but the problem went away after disconnected the Egr, so is it for sure that the valve is bad? Just wanted to make sure there's no other component that could be also be bad. I have a toyota avalon 1997.

- You might be able to get the valve cleaned by spraying cleaner in it or by emersing it in solvent. Check the repair manual and consult with an experienced mechanic. I don't even have a ball park figure of what a new one would cost.

- Q: Is a Head gasket the same thing as the valve cover gasket, on my honda civic si?

- LOL. No. You don't get away that easily. The valve cover gasket only keeps oil from splashing all over the engine bay. It literally covers the valves, sealing the engine interior away from the general environment. Th head is the part of the engine that the valve cover sits on. It contains the valves, and either the camshaft or the rods that lead to a camshaft deeper in the engine, and of course the rocker assembly. You have to remove all those big bolts along the casting to break the head free, and you'll need a torque wrench to get the pressure right when you're reinstalling it. The head gasket seals the tops of the cylinders [incorporated in the bottom of the head] to the cylinders themselves [bored into the block proper.] Have fun!!!!!

- Q: Or could you put a blow off valve on a supercharger?

- No an No

- Q: Hello, I went to my garage last friday because my exhaust emmisions light was on, on my Bora MK4 2003 52 plate 1.6 16V. They said its a faulty EGR valve which could be from being clogged up with sh*t. But they said it would be fine to drive, and that the rough idle wouldn't harm the car, and to unplug it if the rough idle became annoying. Its now sunday 3 days since the garage diagnosed it I drove about 250 miles over these days. With the exhaust emissions light coming on then sometimes going off. I think the EGR Valve keeps sticking closed and the engine is very hard to start. Is there anything I can do to help start the car? which is better having it plugged in or unplugged? how do you take the EGR Valve out and clean it what tools are needed is it complicated. any ideas on how I can help it start ? I've tried unplugging it, it makes no difference really.

- The EGR valve or Exhaust gas Recirculation valve is placed on the exhaust gadget. those frequently get hung up with rust and different exhaust deposits. The motorcar might want to be less than production unit assure being in easy words 3 years old. i might want to examine with a broking service to work out if the motorcar and/or section continues to be less than assure. A defective EGR valve will reason the computing device to make the incorrect settings to the gas and air mix causing the engine to run too prosperous or too lean. Its no longer too unfavourable contained in the little while period, yet your gas mielage will struggle through, and also you are able to fail a state inspection so get it repaired previously then.

- Q: P.S.V. Pressure Safety Valve

- They okorder or other relief valve sites for more information.

- Q: What would be some drivability issues with an EGR valve that is acting up. The valve in question is an electronic egr valve.

- the egr valve can make the vehicle stall it can make it load up with fuel and make the engine miss fire

- Q: how long do people usually live after mitral valve repair?

- depends on luck and how you deal with life?

Send your message to us

Double flanged Metal Seal eccentric butterfly valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords