Decorative Mirror Finish Anodized Aluminum Sheet - 040 Aluminum Sheets in Midnight Bronze

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Decorative Mirror Finish Anodized Aluminum Sheet

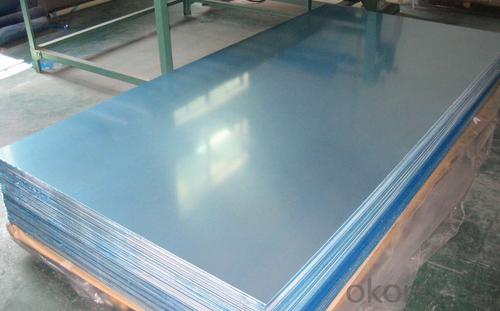

1. Commodity: 5083 Aluminium Plain Sheet for Marine Use

2. Alloy No.: 050 1060 1100 3003 3004 3104 3005 3105 5005 5052 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

4.Application:

1) air plane, refrigerators ,audio equipment

2)building materials: ceilings, walls

3)telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

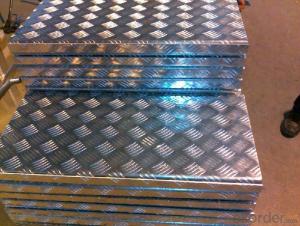

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

1. | Item | Aluminum plate/ Aluminum sheet,aluminium plate price, aluminium chequer plate,aluminium sheet,aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Material | 1060,1200,1100,a1100P,3003,3004,5052,5652,5154,5254,5454,5083, 5086,5056,5456,2A21,2024,2014,6061,6063,7072,7075,etc. | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~3000mm | ||

Length | 2m,3m,5.8m,6m,or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | MOQ | 500kg | |

12. | Export to | Singapore,Indonesia,Ukraine,Korea,Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq,Russia,Malaysia, etc. | |

13. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: What are the different forming methods for aluminum sheets?

- There are several different forming methods that can be used to shape aluminum sheets. These methods include: 1. Roll Forming: This process involves passing the aluminum sheets through a series of rollers that gradually shape the material into the desired form. Roll forming is often used to create long, continuous shapes such as channels or rails. 2. Press Forming: Press forming uses hydraulic or mechanical presses to apply force to the aluminum sheet, creating the desired shape. This method is commonly used for forming complex shapes with tight tolerances. 3. Stretch Forming: In stretch forming, the aluminum sheet is clamped at its edges and then stretched over a die, causing the material to conform to the shape of the die. This method is often used to produce curved or contoured parts. 4. Deep Drawing: Deep drawing involves placing a blank of aluminum sheet into a die and then using a punch to force the material into the die cavity, creating a hollow shape. This method is commonly used to produce cylindrical or box-shaped parts. 5. Hydroforming: Hydroforming uses hydraulic pressure to shape the aluminum sheet against a die. This method is particularly useful for producing complex, intricate shapes with smooth surfaces. 6. Incremental Sheet Forming: In incremental sheet forming, a CNC machine moves a small tool over the surface of the aluminum sheet, gradually shaping it by applying localized pressure. This method is often used for prototyping or small-scale production. These forming methods offer different advantages and are suitable for different applications. The choice of method depends on factors such as the desired shape, complexity, and volume of production.

- Q: what's the temperature tolerance of aluminum sheets?

- aluminum is a kind of silver white metal,melting point:660.4℃, boiling point: 2467℃,density: 2.70 g/cm?,very light, about 1/4 of iron's density.it has low hardness and good ductility, which makes it suitable for being pulled into threadlets or pressed into aluminum foils, and the later is usually used for packaging candy and cigarette. it has good electrical and temperature conductivity. it's used for the manufacture of electric wire and cable in electric power industry, and for the manufacture of cooker in daily life bined with the magnesium , copper,zinc,tin,manganese,chromium,zirconium,silicon and other elments,it can formulate various alloys that is broadly used for the manufacture of airplane,car,ship, materials of daily living equipment and the doors and windows of construction industry.aluminum is one of the best reflectors of heat and light, so it is used as thermal insulation material and the manufacture of reflecting mirror in the reflecting telescope.

- Q: Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Q: The question asks if it is possible to recycle used aluminum foil to create new aluminum sheets.

- <p>Yes, recycled aluminum foil can be used to make new aluminum sheets. The process involves collecting and sorting the foil, which is then cleaned and melted down. The molten aluminum is poured into molds or rolled into sheets, creating new aluminum products. This recycling method is not only environmentally friendly but also economically viable as it saves energy compared to producing aluminum from raw materials.</p>

- Q: What are the different fabrication methods used for aluminum sheets?

- Aluminum sheets undergo various fabrication methods, each presenting its own advantages and applications. Rolling, extrusion, casting, and stamping are among the most commonly employed techniques. Rolling, the most prevalent method, entails passing the aluminum through a series of rollers to reduce thickness and form a flat sheet. This approach allows for precise control over sheet thickness and shape, rendering it suitable for an array of applications, from packaging to building materials. Another well-received method is extrusion, where heated aluminum is pushed through a die to create a specific shape or profile. This technique is commonly employed to manufacture intricate shapes like tubes, rods, and channels. Extruded aluminum sheets exhibit high strength and durability, making them appropriate for structural applications in construction and automotive industries. Casting involves pouring molten aluminum into a mold, allowing it to solidify. This method is frequently used for producing intricate shapes that are challenging to achieve through other means. Cast aluminum sheets can boast unique textures and designs, making them popular for decorative purposes. Stamping utilizes a press to shape the aluminum sheet by exerting pressure and forming it into the desired shape. This technique is commonly utilized for creating precise, small parts such as brackets, connectors, and electrical components. Stamped aluminum sheets offer exceptional dimensional accuracy and can be produced in large quantities at a relatively low cost. Additionally, other fabrication techniques such as welding, bending, and laser cutting can be employed to further process aluminum sheets and craft custom shapes and designs. In conclusion, the choice of fabrication method for aluminum sheets relies on the desired application, required properties, and complexity of the desired shape. Each method possesses unique advantages and capabilities, enabling a broad range of possibilities in aluminum sheet fabrication.

- Q: What type of aluminium sheet is a food grade?

- You can inquire about our company: dexincheng Pioneer Metals corporation. Baidu will find the phone soon.

- Q: im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: what's the difference between zinc sheet and aluminum sheet?

- Only the zinc sheet reacts after adding concentrated nitric acid in drops ,zinc is amphoteric.

- Q: How do I calculate the weight of aluminum sheet? What is the density?

- Weight by volume * density. With the quality, volume density.

Send your message to us

Decorative Mirror Finish Anodized Aluminum Sheet - 040 Aluminum Sheets in Midnight Bronze

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords