cylindrical roller bearing used mower wheels bearings NJ 202 E

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Structure: | Cylindrical | Type: | Roller | Brand Name: | OEM |

| Bore Size: | 15 mm | Outside Diameter: | 35 mm | Model Number: | NJ 202 E |

| Precision Rating: | P0, P6, P5, P4 | Seals Type: | open type | Number of Row: | Single row/ Double row |

| Place of Origin: | Jiangsu, China (Mainland) | Keyword: | Cylindrical Roller Bearing | Package: | standard export package |

| Cage: | Nylon, Steel, Brass | Material: | Gcr 15 | Precision rating: | P0, P6, P5, P4, P2 |

| Number of row: | Single-row/ Double-row | Certificate: | ISO9001:2000 | OEM: | Acceptable |

| Original: | Made in China |

Cylindrical Roller Bearing Introduction

Rolling body is cylindrical roller bearings - Radial. Cylindrical roller bearings internal structure of the roller was 90 ° perpendicular cross arrangement (which is also cross roller bearings origin of the name), equipped with a gap between the roller cage or spacers can prevent tilting roller or rollers mutual ground between the police, effectively preventing the increase in rotational torque.

Cylindrical roller and raceway for the line contact bearings. Load capacity, the main radial load. Rolling ring wall friction is small, suitable for high-speed rotation. According to ring without ribs, can be divided NU, NJ, NUP, N, NF and other single row cylindrical roller bearings, and NNU, NN and other double row cylindrical roller bearings. The bearing is the inner, outer separable structure.

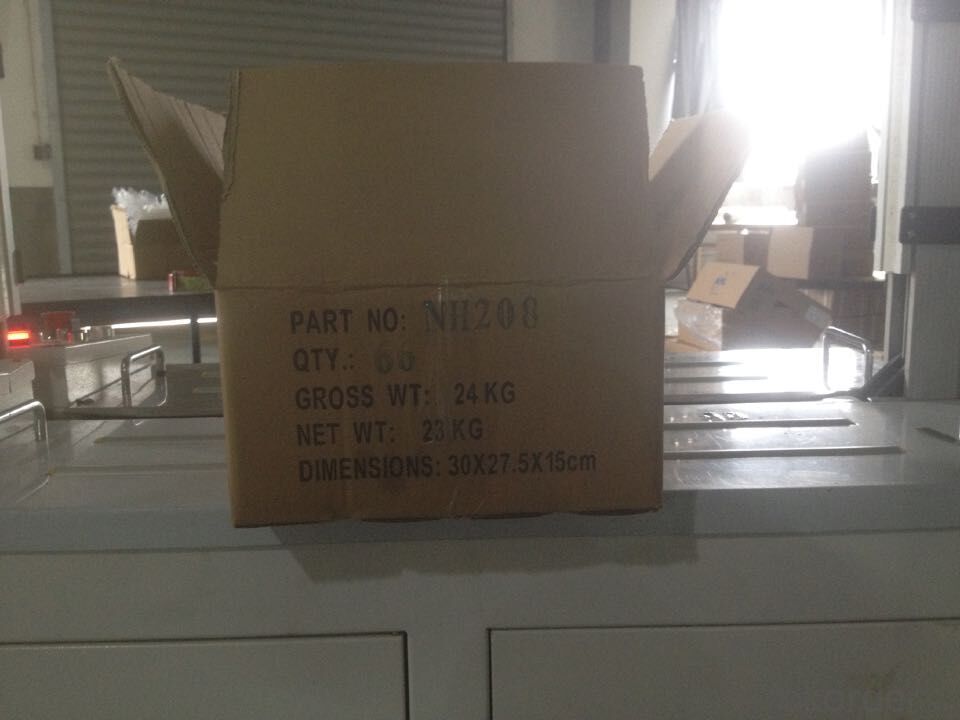

Packaging & Delivery

| Packaging Details: | Cylindrical roller bearing (1)Plastic bins +carton box+ wooden case + pallet (2) According to customers' requirements |

| Delivery Detail: | 5-30days according to the quantity and your request |

- Q: Gb/t283 cylindrical roller bearing age number?

- Hello, it's 2007.GB/T 283-2007 roller bearings cylindrical roller bearings overall dimensionsStandard number: GB/T 283-2007Rolling bearings - cylindrical roller bearings - DimensionsRolling bearings - cylindrical roller bearings - DimensionsEnglish, Name:Rolling, bearings - Cylindrical, rolling, bearings - Boundary - Dimensions

- Q: How much is the shaft shoulder height of the 81105 cylindrical roller bearings with inner diameter 25mm?

- The shoulder height (diameter) shall be smaller than the big diameter of the bearing (less than 42), mainly for easy unloading.

- Q: Full use cylindrical roller bearings, uses and advantages?

- Otherwise, due to lack of lubrication and high-speed operation will cause more wear and tear. I am a bearing

- Q: What are the differences between cylindrical roller bearings nu208m and nu208em?

- E means "reinforced", "rolling", "thickening", "change", "change".. Hope to adopt!!

- Q: Can you make it clear? I don't understand. Thank you for being here first.

- The rollers refer to the rolling bodies as cylinders and similar cylindrical shapes, such as short columns, long columns, tapered rollers, spherical rollers, etc..

- Q: Attention problems of cylindrical roller bearings

- 4, when the interference is large, the oil bath heating or inductor heating bearings can be used to install the heating temperature range of 80 degrees -100 DEG C, the maximum can not exceed 120 degrees centigrade. At the same time, the nut or other appropriate method is used to fasten the bearing so as to prevent the contraction of the bearing in the direction of width and to create a gap between the collar and the shaft shoulder. 5, single row tapered roller bearings installed, the final adjustment should be clearance. The clearance value shall be determined according to the working conditions and the magnitude of the interference fit. Test shall be carried out when necessary. Double row tapered roller bearings and pump shaft bearings have been adjusted for clearance at the factory, and no adjustment is necessary during installation. 6, the bearing should be installed after the rotation test, the first for the rotary shaft or bearing box, without exception, then the power for no load, low speed operation, and then gradually increase as the functioning of the rotation speed and load, and to detect noise, vibration and temperature, abnormal, should stop running and check. The running test is normal and can be used before delivery.

- Q: My notes is the former has a taper hole on the cone position preload, the latter is a nut. But the online information seems a little different. Are the preload methods for two direction thrust angular contact bearings and angular contact ball bearings the same?

- Dissimilarity! The former is mainly used as the support of the shaft with larger load. The main prevention is the radial runout, which is usually used individually, so there is not much demand for the preload. The latter is mainly used as a precision screw shaft for the radial motion and axial runout requirements are very strict, generally used when they are two back-to-back, when pre tightening have strict requirements, general requirements for the radial motion and axial runout should not exceed 5 per thousand mm.

- Q: Why cylindrical roller bearings can not bear axial load?.

- The thrust bearing retainer plate and two pieces of circular hole of the ball and the ball hole and shaft wear in the park, circular plate, steel ball track between two plate, shaft and the bearing seat of the top plate in the round two sides, in addition to the track groove, it is not binding the radial direction, so it cannot withstand the radial load.The radial bearing by the size of the two steel ring, steel ball size between steel ring, steel ring diameter fixed by a bearing seat, shaft mounted on a small steel ring, binding only in the radial direction and axial direction of the load is not binding, so it cannot withstand the axial diameter.

- Q: Rolling bearing face to face or back to back on the use of cylindrical roller bearing pairs, the speed limit will be reduced? Please, thank you!

- Cylindrical roller bearings themselves require that the applied speed can not be too high, especially in short axis applications

- Q: How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- 3, the bearing clearance in different conditions: the bearing clearance can be changed under different conditions, in particular, can be divided into: 1) the original clearance: the original bearing clearance refers to the complete installation in front of the machine after the bearings, the clearance in a free state of the. In fact, the original clearance is not to be measured by measurement, so the original clearance is often replaced by a test clearance. The inspection is in clearance inspection status, applied in measuring load conditions, clearance data instruments detection and, strictly speaking with the original bearing clearance is not the same, but little difference in the readings on the two in general, so it can replace each other without causing much error. 2) effective clearance: effective clearance, or work clearance, refers to the bearing in the installation of the host, in a certain load, to a certain temperature rise in a stable state of operation, bearings exist in the actual clearance. Obviously, the effective clearance is smaller than the original clearance.And 4, bearing clearance: clearance of bearing is to ensure that the bearings are to operate flexibly without blocking, but also requires that can ensure the bearing running smoothly, the bearing axis has no significant settlement, and the number of rolling elements bear the load as much as possible. Therefore, the clearance of the bearing has a great influence on the dynamic performance of the bearing (noise, vibration and friction) and the rotation accuracy, and the carrying capacity (wear and fatigue) of the bearing.

Send your message to us

cylindrical roller bearing used mower wheels bearings NJ 202 E

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords