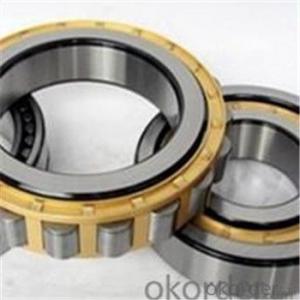

Cylindrical Roller Bearing , Chinese Factory NU 2305 E

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Cylindrical roller and race for line contact bearing. Load capacity is big, mainly bear radial load .

1. Friction coefficient is small, suitable for high speed limit speed close to deep groove ball bearings

2.N and NU type axial movement, can adapt to shaft caused by thermal expansion or installation error and shell the change of relative position, can be used for free end bearing

3. On the shaft or hole of the processing and the demand is higher, bearing outer axis relative deflection after installation to be kept under strict control, so as not to cause contactstress concentration

4. Inner ring or outer ring separable, easy to install and remove

Specification | Model No.: NU 2305 E |

Brand Name: OEM | |

Size:25*62*24mm | |

Net weight: 0.35kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

Packaging & Delivery

Packaging Details: | plastics wrapping bearings - wrapping papers - polywoven bag - carton for outside package - wooden box /According to your order |

Delivery Detail: | 30-40days/according to your order |

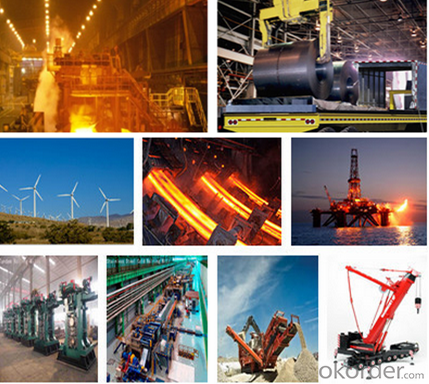

Product Applications:

Cylindrical Roller Bearing Application Flied:Rolling Mills,Crusher,Mining

Metallurgy Petroleum,Chemical Industry,Engineering Machinery,Port,Oil,Gas,

Wind,Agriculture,Lathe,CNC,Steel Works,Electrical Machinery,Axle/Limber,

Tractor,Autocar,Crude Oil Engine and so on.

Our advantages

1. Provide full range of standard bearings.

2.Look into and develop various non-standard bearing according to customers’ special needs.

3.Eager to control quality and ensure quality for bearings.

4. Multi-channel sales modes: e-commerce, regular domestic and foreign exhibitors.

5.Perfect logistics modes: sea, air & international express.

6.High quality post-sales service: find solutions to fulfill your needs in time.

- Q: Why are cylindrical roller bearings suitable for traveling support?

- Cylindrical roller bearings without inner sides of the inner ring or outer ring, whose inner and outer rings can be moved relative to the axial direction, so they can be used as free end bearings.

- Q: How are the twin row cylindrical roller bearings classified?

- The NN0000K type conical bore double row cylindrical roller bearingThis kind of bearing is compact in structure and bears little deformation under load, so it is suitable for the support of spindle of machine tool. The inner bore of the bearing is taper, and the radial clearance of the bearing can be adjusted slightly.This kind of bearing with no outer wall, so you can install the outer ring and the inner ring assembly respectively (with roller and cage), does not limit the axial displacement of the shaft or shell, cylindrical roller bearing with the same radial size is compared, can bear larger radial load.

- Q: Attention problems of cylindrical roller bearings

- 4, when the interference is large, the oil bath heating or inductor heating bearings can be used to install the heating temperature range of 80 degrees -100 DEG C, the maximum can not exceed 120 degrees centigrade. At the same time, the nut or other appropriate method is used to fasten the bearing so as to prevent the contraction of the bearing in the direction of width and to create a gap between the collar and the shaft shoulder. 5, single row tapered roller bearings installed, the final adjustment should be clearance. The clearance value shall be determined according to the working conditions and the magnitude of the interference fit. Test shall be carried out when necessary. Double row tapered roller bearings and pump shaft bearings have been adjusted for clearance at the factory, and no adjustment is necessary during installation. 6, the bearing should be installed after the rotation test, the first for the rotary shaft or bearing box, without exception, then the power for no load, low speed operation, and then gradually increase as the functioning of the rotation speed and load, and to detect noise, vibration and temperature, abnormal, should stop running and check. The running test is normal and can be used before delivery.

- Q: My notes is the former has a taper hole on the cone position preload, the latter is a nut. But the online information seems a little different. Are the preload methods for two direction thrust angular contact bearings and angular contact ball bearings the same?

- Dissimilarity! The former is mainly used as the support of the shaft with larger load. The main prevention is the radial runout, which is usually used individually, so there is not much demand for the preload.

- Q: cylindrical roller bearings N210 20Deep groove ball bearings 6120, self-aligning ball bearings 1210, cylindrical roller bearings N210 in the same radial force conditions, the life expectancy of the three levels and how to compare? What is the cause of the high and low?

- Summary: the above three kinds of bearings, the service life in accordance with the order from high to low: deep groove ball bearings, self-aligning ball bearings, cylindrical roller bearings.

- Q: Why does cylindrical roller bearings fail abnormally?

- Generally, the causes of abnormal failure of cylindrical roller bearings are as follows:1, cylindrical roller bearing manufacturing accuracy is poor, one end of the bearings with loose, and travel source is larger, bearing frame rigidity is poor. Or the bottom of the bearing seat is uneven.2, cylindrical roller bearings axis misalignment (misalignment) axis and the housing of the shoulder to the surface is not vertical, shell installation, bearing two or more holes, different axis.

- Q: What are the components of cylindrical roller bearings?

- Cylindrical roller bearings are usually guided by two blocks of a bearing ring. The cage, roller, and guide ring form a composite, generally separable bearing.

- Q: What is called a semi convex roller, a fully convex roller, a logarithmic curve roller?

- What is called a semi convex roller, a fully convex roller, a logarithmic curve roller?Semi convex, convex roller is in plane roller axis, the outer surface of a continuous or discontinuous convex curved basic cylindrical or conical roller, to prevent the end of the roller and raceway contact stress concentration. The roller is generally defined as a convex roller and a modified roller.

- Q: The Russian bearing suffix No. ZST is a cylindrical roller bearing

- Well, you have to write out the whole model. The suffix code is not used to distinguish the bearings, but it helps to explain the structure of the bearings and the material.

- Q: Thrust cylindrical roller bearings, the main use?

- Thrust cylindrical roller bearings, the main use? Thrust cylindrical roller bearings are mainly used in oil rigs, iron, steel, machinery and so on. Our factory uses the bearings of Changzhou Enke Bearing Co., Ltd., they have many kinds of bearings and meet various demands.

Send your message to us

Cylindrical Roller Bearing , Chinese Factory NU 2305 E

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords