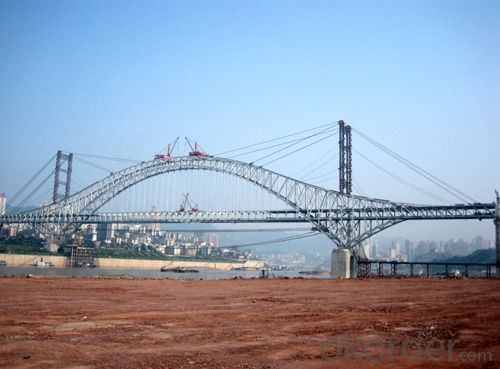

Customized steel structure for bridge

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

| Model Number | B |

| Material | Metal |

| Drawing for design | According to your requirement.We can quote according to your drawing. |

| Surface Treatment | Hot galvanized,painted,powder coated |

Packing Details

| a)Steel strip. |

| b)According to the customers' requirement |

Payments and Shipping Terms

| MOQ | 25 Ton |

| Supply Ability | 100 ton/Month |

| Payment Term | a)L/C b)T/T |

| FOB Shanghai Price | USD1000-1200/Ton |

Check Below for more imformation on placing an order

| 1. Inquiry-Professional quotation. |

| 2. Confirm the price, lead time, payment term etc. |

| 3. Our sales send the Proforma Invoice. |

| 4.Customer make the payment for deposit and send us Bank receipt. |

5.We will arrange the production & inform the estimated time. |

6. Middle Production:send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

7. End Production:Mass production products photos will send to you for approval. You can also arrange the third party Inspection. |

8. Clients make payment for balance and we Ship the goods .Also can accept payment term-Balance against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients. |

9. Order can be say “finish” when you receive the goods and satisfy with them . |

10. Feedback to us about Quality , Service, Market Feedback & Suggestion. And we will do better. |

- Q: What are the factors to consider when designing a steel structure?

- When designing a steel structure, several factors need to be considered, including the specific purpose and function of the structure, the load it will bear, the environmental conditions it will be exposed to, the available budget, and the desired aesthetic appearance. Additionally, factors such as material selection, structural stability, durability, and constructability must also be taken into account to ensure a safe and efficient design.

- Q: What factors need to be considered when designing steel structures?

- When designing steel structures, several factors need to be considered. These include the structural requirements such as load-bearing capacity and stability, as well as the intended purpose and function of the structure. Other important factors include the location and environment where the structure will be placed, the type of steel to be used, and the cost-effectiveness of the design. Additionally, factors like seismic activity, wind loads, and potential corrosion also need to be taken into account to ensure the durability and safety of the steel structure.

- Q: What are the design considerations for steel staircases?

- Some key design considerations for steel staircases include structural stability, load-bearing capacity, proper dimensions and proportions, safety features such as handrails and non-slip surfaces, aesthetics, ease of maintenance and durability, and compliance with building codes and regulations.

- Q: What are the advantages of using steel in construction?

- There are several advantages of using steel in construction. Firstly, steel is incredibly strong and durable, providing exceptional structural integrity to buildings. It has a high strength-to-weight ratio, allowing for the construction of larger and taller structures with less material. Additionally, steel is resistant to many environmental factors, including fire, earthquakes, and severe weather conditions. It is also a sustainable material, as it can be recycled and reused, reducing the demand for new resources. Moreover, steel offers flexibility in design and can be easily modified or expanded. Overall, these advantages make steel a preferred choice for construction due to its strength, durability, safety, sustainability, and design versatility.

- Q: How are steel structures designed for warehouses?

- Steel structures for warehouses are typically designed by a team of structural engineers who consider factors such as the size and height of the warehouse, the weight of the goods to be stored, and the local weather conditions. The design process involves determining the appropriate type and thickness of steel beams and columns, as well as the spacing and connections between them, ensuring the structure can withstand the expected loads and provide sufficient stability. Additionally, considerations for fire safety, accessibility, and future expansion may also influence the design of steel structures for warehouses.

- Q: What are the design considerations for steel canopies?

- To ensure a safe and effective structure, several important considerations must be taken into account when designing steel canopies. These considerations include: 1. Ensuring structural integrity: The steel canopy must be able to withstand various loads, such as wind, snow, and potential seismic activity. The design should consider the specific location and environmental conditions to ensure stability and security. 2. Selecting the right materials: The type and grade of steel used in the construction of the canopy are crucial. Factors such as strength, corrosion resistance, and durability must be considered. The chosen steel should have sufficient strength to bear the load and resist external forces. 3. Implementing weather resistance measures: Canopies are exposed to different weather conditions, including rain, snow, and extreme temperatures. The design should incorporate measures to ensure proper water drainage, prevent snow accumulation, and protect against moisture-induced corrosion. 4. Considering aesthetics: Steel canopies are often used to enhance the visual appeal of a building or space. The design should take into account the overall aesthetics, matching the architectural style and complementing the surrounding environment. 5. Prioritizing accessibility and safety: Canopies should be designed with accessibility in mind, ensuring that people of all abilities can navigate comfortably and safely underneath. The design should include considerations such as clearance height, lighting, and the use of non-slip surfaces. 6. Planning for maintenance and durability: Steel canopies should be designed for long-term durability and easy maintenance. This may involve incorporating protective coatings, providing easy access for cleaning or repairs, and considering the canopy's lifespan. 7. Striving for cost efficiency: The design should aim to achieve the desired functionality and aesthetics while being mindful of cost. Optimizing the size, shape, and materials used can help strike a balance between cost and performance. In summary, designing steel canopies requires a multidisciplinary approach that combines structural engineering, architectural design, weatherproofing, accessibility, and cost optimization. By carefully considering all these factors, a well-designed steel canopy can serve as a visually appealing, durable, and functional addition to any building or outdoor space.

- Q: What are the different types of steel clamps used in steel structures?

- There are several types of steel clamps used in steel structures, including beam clamps, pipe clamps, angle clamps, and flange clamps. Each type is designed to securely fasten and support different components of the steel structure, such as beams, pipes, angles, and flanges, ensuring structural integrity and stability.

- Q: Steel structure platform cost

- The steel structure (General Plant) length: 100 meters wide, 30 meters high, 8 meters (total: 3000 square meters): steel frame (plant): 700 yuan / month (700 * 46=32200) steel: 200 yuan / square meter (200 x 3000=600000) wall: 90 yuan / square meter (90 x 3000=270000) total cost cost: 902200 yuan, 300 yuan / square meters of steel structure service life (25 years)

- Q: What is the role of steel purlins in a structure?

- Steel purlins play a crucial role in the structural integrity and support of a building. They are horizontal structural members that are used to provide stability and support to the roof and walls of a structure. The primary function of steel purlins is to transfer the load of the roof or walls to the main structural members, such as columns or rafters. By acting as a structural brace, steel purlins help distribute the weight of the roof evenly, preventing any excessive stress or strain on the walls or columns. This helps to maintain the overall stability of the structure. Additionally, steel purlins also serve as a base for attaching the roof or wall cladding. They provide a secure and stable platform for fixing the roofing or walling materials, ensuring that they are properly supported and protected. By providing a solid foundation for the cladding, steel purlins help enhance the durability and longevity of the building envelope. Furthermore, steel purlins also contribute to the overall efficiency and cost-effectiveness of a structure. They are lightweight yet strong, which makes them easy to handle and install. This reduces the labor and construction time required, resulting in cost savings. Additionally, their corrosion-resistant properties make them suitable for various weather conditions, further reducing maintenance costs in the long run. In summary, the role of steel purlins in a structure is to provide support, stability, and load distribution to the roof and walls. They also serve as a base for attaching cladding materials and contribute to the overall efficiency and cost-effectiveness of the building.

- Q: How are steel structures designed to minimize the risk of structural failure?

- Steel structures are designed with several key considerations in order to minimize the risk of structural failure. Firstly, the design process involves a thorough analysis of the forces that the structure will be subjected to, such as gravity, wind, seismic activity, and live loads. This analysis helps determine the appropriate size and configuration of the steel members, ensuring that they can safely resist these forces without experiencing excessive stress or deformation. Secondly, steel structures are designed with redundancy in mind. Redundancy refers to the inclusion of extra structural members or connections to ensure that if one component fails, there are alternative load paths to distribute the forces and prevent catastrophic failure. This redundancy increases the overall safety and reliability of the structure. Another important aspect of steel structure design is the consideration of potential failure modes. Engineers take into account factors such as buckling, fatigue, and brittle fracture to design the structure in a way that minimizes the risk of these failure modes occurring. For example, appropriate bracing and stiffeners may be added to prevent buckling, and fatigue-resistant details may be incorporated to resist cyclic loading. Additionally, steel structures are designed with proper connections and joints to ensure structural integrity. The connections between steel members are carefully designed and detailed to provide sufficient strength and stiffness, as well as to accommodate potential movement or deformations. This helps to prevent the failure of individual components and ensures the overall stability of the structure. Finally, steel structures are designed with consideration for maintenance and inspections. Regular inspections and maintenance routines are implemented to detect any signs of deterioration, such as corrosion or fatigue cracking, which could compromise the structural integrity. By addressing these issues promptly, the risk of structural failure can be minimized. Overall, the design of steel structures incorporates factors such as load analysis, redundancy, failure mode consideration, proper connections, and maintenance to ensure the safety and reliability of the structure, minimizing the risk of structural failure.

Send your message to us

Customized steel structure for bridge

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords