Construction Material All Type Color Coated Galvanized Steel /PPGL Steel roofing Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction Material All Type Color Coated Galvanized Steel /PPGL Steel Roofing Sheets

1. Detailed Specifications:

| Product | PPGI Color Coated Galvanized Steel Sheet/Coloful Steel Coil |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Construction Material All Type Color Coated Galvanized Steel /PPGL Steel Roofing Sheets

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

.Manufacture anticorrosion, industrial and roof boarding,roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils.

.Corrosion resistant parts of cars.

.Food storage, meat and aquatic products’ freezing and processing equipment.

.The equipments to store and transport materials, and packing implements.

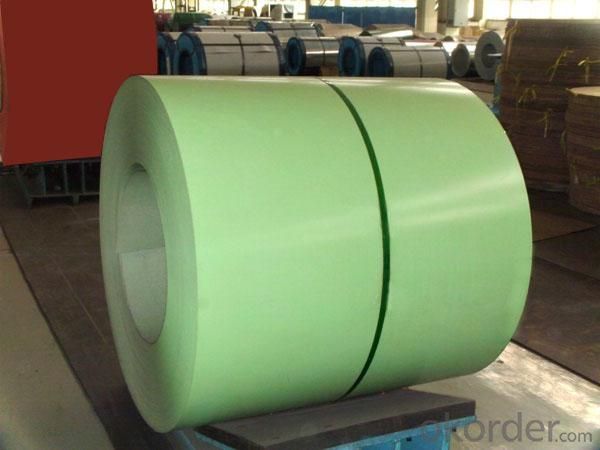

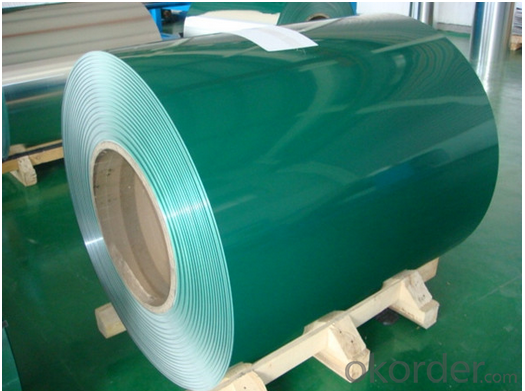

3. Construction Material All Type Color Coated Galvanized Steel /PPGL Steel Roofing Sheets Images:

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- Steel has more mass.

- Q: 420 440 1045 or 1065 ive bought knifes with these steel grades and i want to know which one is better.

- SAE 440 is the best. Classified as high grade cutlery steel. There are various grades of 440: A, B, C, and F. 440 A is the most stain resistant while 440 C has the most carbon and can achieve the highest hardness (Best edge Retention). SAE 440 Chemistry: 16 - 18% Chromium, 0.60 - 1.2% Carbon, 0.75% Molybdenum. SAE 420 is pretty good. Classified as cutlery steel, it is a stain resistant grade but has less chromium and significantly less carbon than SAE 440. SAE 420 Chemistry: 12 - 14% Chromium, 0.15% Carbon (min), 0 Molybdenum Chromium is what makes the steel corrosion resistant. It also adds toughness. Molybdenum adds extra corrosion resistance and adds hardenability. So you can see by chemical components that 440 is highest quality although that also means more cost. 1045 and 1065 are low quality steels and you should probably never use them for a knife. The 1 indicates plain carbon steel with little other alloying elements. The last two digits indicate how much carbon is in the steel. 1045 has 0.45% carbon, mid-range hardenability. 1065 has 0.65% carbon, high hardenability. So if I had to choose I would choose 1065 over 1045 but the difference isn't that noticeable. Everything I said here assumes they have all had the optimum Quench and Temper heat-treatment for their chemistry grade.

- Q: What are the dimensions of steel coils used in the agricultural equipment industry?

- The dimensions of steel coils utilized in the agricultural equipment sector differ based on the precise application and equipment requirements. Nevertheless, there are several prevalent dimensions for steel coils employed in this industry, spanning from 0.5mm to 6mm in thickness and 600mm to 2000mm in width. The length of the coils can be tailored to suit the particular equipment demands. Furthermore, the weight of the coils can fluctuate, generally ranging from a few hundred kilograms to multiple tons. It is crucial to acknowledge that these dimensions are not set in stone and may vary depending on the manufacturer and the specific agricultural equipment being manufactured.

- Q: Can steel coils be coated with anti-microbial materials?

- Yes, steel coils can be coated with anti-microbial materials to provide protection against the growth of bacteria and other microorganisms.

- Q: What would be a better knife one with damascus steel or one without? Why is damascus steel so special other than the look? And why do some people say high carbon steel is better than regular? mainly though I want to know about the damascus. Thanks, max points to best answer.

- Damascus steel was a great steel in it's time. Because it was one of the few ways to make good steel from iron. But today there are much better steels available. Damascus steel was a very labor intensive process, a single knife would cost many thousands of dollars today. The Damascus steel knives are not actually Damascus steel, the pattern is etched on or engraved on. In fact the Damascus steel knives I saw reviewed on Consumer Reports are ceramic blades, not even steel at all. Bottom line, any Damascus steel knives are just a pattern on standard steel, no different from the others. It's a marketing gimmick.

- Q: How are steel coils used in the production of metal containers?

- Due to their versatility and strength, steel coils find wide application in the production of metal containers. Each stage of manufacturing metal containers relies heavily on steel coils. To begin with, steel coils serve as the primary raw material for metal container production. These coils consist of high-quality steel that is rolled into a continuous sheet, ensuring consistent thickness and durability. Subsequently, this sheet is cut into specific widths and lengths according to the container size requirements. Once the desired dimensions are achieved, various techniques are employed to shape the steel coils into container form. Roll forming, for example, is a commonly used method where the steel coil passes through a series of roll dies that gradually shape it into the desired container shape. This technique allows for the creation of containers in different sizes and designs, ranging from cans and drums to large industrial containers. After the initial forming process, the steel coils undergo further processing to enhance their strength and durability. Heat treatment is one such process where the coils are exposed to high temperatures to increase their hardness and resistance to wear and tear. Additionally, annealing and quenching methods may be employed to improve the steel's properties. Once the containers are formed and processed, additional fabrication steps, such as welding or sealing, are carried out to ensure their structural integrity. Steel coils are frequently utilized in these processes as they provide a robust and dependable material for creating sturdy seams and joints. Finally, metal containers receive various coatings or treatments to protect them from rust, corrosion, and other environmental factors. Steel coils can be coated with materials like paint, epoxy, or zinc to enhance their resistance to these elements, ultimately ensuring the longevity of the containers. In conclusion, steel coils play a crucial role in the production of metal containers. They serve as the primary raw material, aid in forming, processing, and finishing, and provide the necessary strength, durability, and versatility required for manufacturing reliable metal containers across a range of industries.

- Q: How are steel coils used in the production of steel brackets?

- Steel coils are used in the production of steel brackets by being processed and cut into the desired shape and size. The coils serve as the primary raw material, providing the necessary strength and durability for the brackets.

- Q: How are steel coils used in the production of storage racks and shelving?

- Steel coils are a crucial component in the manufacturing process of storage racks and shelving. These coils are typically made from high-quality steel that is rolled into a long, continuous strip. The steel coils are then processed and transformed into various forms, such as sheets or strips, which are used to create the frames, shelves, and other structural components of storage racks and shelving systems. Firstly, the steel coils are unwound and flattened through a series of machines, ensuring uniform thickness and width. This process enables manufacturers to obtain sheets or strips of steel with consistent dimensions, which are essential for the production of storage racks and shelving that need to meet specific design specifications and structural requirements. Once the steel coils are flattened and cut into the desired sizes, they are further processed to add necessary features and characteristics. This can involve bending, punching, or welding the steel to create the desired shapes, such as uprights, beams, or brackets for the storage racks and shelving. These components are then assembled together to form the framework of the storage system. The durability and strength of steel make it an ideal material for storage racks and shelving. Steel coils provide the necessary structural integrity and load-bearing capacity required to support heavy items and withstand the rigors of everyday use. Additionally, steel is resistant to corrosion, which ensures the longevity and reliability of the storage racks and shelving systems. Furthermore, steel coils can be coated or galvanized to enhance their resistance to rust and corrosion. This protective layer helps to maintain the aesthetic appeal and structural integrity of the storage racks and shelving, especially in environments with high humidity or exposure to moisture. In summary, steel coils play a vital role in the production of storage racks and shelving. They provide the raw material from which various components are fabricated, ensuring the strength, durability, and load-bearing capacity necessary for these storage systems. The versatility and adaptability of steel allow manufacturers to create storage racks and shelving that meet specific design requirements and offer long-lasting storage solutions for a wide range of applications.

- Q: Monopolistic competition means all of their products are identical like things in supermarket like milk. There are no high barriers to entry. Oil and steel are all same in all industries.

- That okorder /

- Q: How do steel coils compare to other materials?

- Steel coils have several advantages over other materials. Firstly, steel is known for its high strength and durability. This makes steel coils highly resistant to wear and tear, making them suitable for a wide range of applications. Additionally, steel coils have excellent heat resistance, making them ideal for use in high-temperature environments. Furthermore, steel coils have superior corrosion resistance compared to many other materials. This is especially important in industries such as construction and automotive, where exposure to moisture and chemicals is common. Steel coils can withstand these harsh conditions, ensuring long-lasting performance and reliability. Another advantage of steel coils is their versatility. Steel can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. This makes steel coils suitable for a wide range of applications, including manufacturing, construction, transportation, and energy industries. Moreover, steel coils offer good value for money. Despite their numerous benefits, steel coils are generally more affordable compared to other materials such as aluminum or copper. This makes steel coils a cost-effective choice for businesses and industries looking for high-quality and reliable materials. In summary, steel coils have several advantages over other materials. They offer high strength, durability, and heat resistance, along with superior corrosion resistance. Steel coils are also versatile and can be easily customized to suit different applications. Additionally, they provide good value for money. Overall, steel coils are a reliable and efficient choice for various industries and applications.

Send your message to us

Construction Material All Type Color Coated Galvanized Steel /PPGL Steel roofing Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords