Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Plastic Formwork Concrete Formwork Parts Of A Tubular Scaffolding Scaffolding Importers Low Price

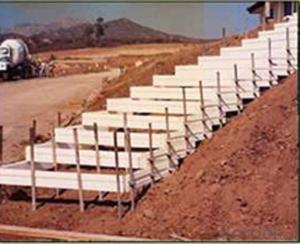

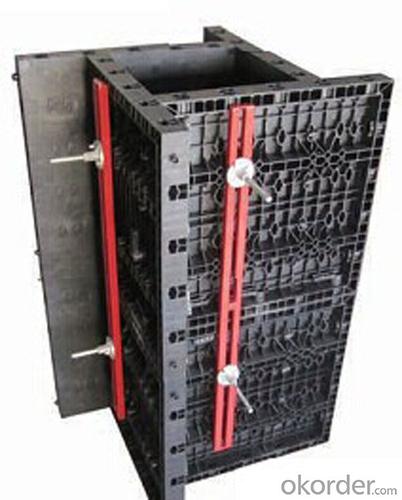

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

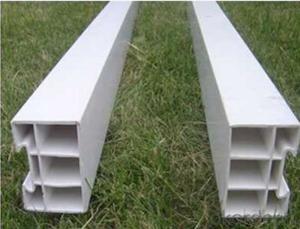

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

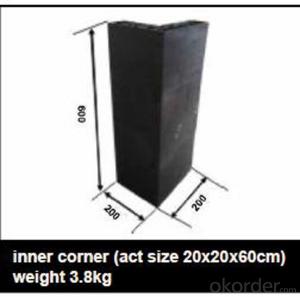

3.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

FAQ

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

We have organized several common questions for our clients, may help you sincerely:

1)How is the Packaging Details?

In bags or as the requirement ofcustomers.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q: How does steel frame formwork handle different types of formwork joint arrangements?

- Steel frame formwork is a versatile and robust system that can handle different types of formwork joint arrangements with ease. This type of formwork is designed to be adjustable and flexible, allowing for various configurations and combinations of joints. One common type of formwork joint arrangement is the butt joint, where two formwork panels meet end-to-end. Steel frame formwork is designed with special connectors and clamps that securely hold the panels together, ensuring a tight and seamless joint. These connectors are adjustable, allowing for precise alignment of the panels to achieve the desired formwork shape and dimensions. Another type of joint arrangement is the corner joint, where two formwork panels meet at a 90-degree angle. Steel frame formwork is equipped with corner connectors that securely hold the panels together at the desired angle. These connectors are adjustable as well, allowing for precise alignment and ensuring a strong and stable corner joint. In addition to butt and corner joints, steel frame formwork can also handle other types of joint arrangements such as T-joints, cross joints, and Y-joints. The adjustable connectors and clamps of steel frame formwork enable easy assembly and disassembly of the panels, making it possible to create various joint configurations as required by the specific formwork design. Furthermore, steel frame formwork provides excellent stability and load-bearing capacity, making it suitable for handling different types of joint arrangements even in complex and demanding construction projects. The steel frames and panels are designed to withstand the pressure and forces exerted during the concrete pouring and curing process, ensuring the integrity and strength of the formwork joints. Overall, steel frame formwork is a reliable and efficient system that can handle different types of formwork joint arrangements. Its adjustable connectors and clamps, along with its stability and load-bearing capacity, make it a preferred choice for various construction applications.

- Q: How does steel frame formwork help in achieving accurate dimensions?

- Steel frame formwork helps in achieving accurate dimensions by providing a rigid and stable structure that ensures precise alignment and positioning of the concrete elements. The steel frames act as a guide and support system, allowing for consistent and uniform pouring of the concrete. Additionally, the inherent strength of steel minimizes any flexing or movement during the pouring and curing process, resulting in accurately measured and dimensioned concrete structures.

- Q: Can steel frame formwork be used for both residential and industrial construction?

- Yes, steel frame formwork can be used for both residential and industrial construction. Steel frame formwork is a versatile and durable construction method that is suitable for various types of projects. It provides strength and stability to the structure, making it suitable for both residential buildings and industrial facilities. Additionally, steel frame formwork offers flexibility in design, allowing for customization to meet the specific requirements of residential and industrial construction. Its ability to withstand heavy loads and provide a consistent finish makes it a preferred choice for both types of construction projects.

- Q: How does steel frame formwork help in reducing material waste?

- Several ways are employed by steel frame formwork to reduce material waste. To begin with, steel frame formwork exhibits high durability and can be reused multiple times. Unlike traditional wooden formwork that often needs to be discarded after a few uses, steel formwork can withstand numerous construction cycles without compromising its structural integrity. As a result, less material is required for each construction project since the same formwork can be repeatedly utilized. In addition, steel frame formwork is adjustable and can be customized. This enables precise shaping and sizing of concrete structures, consequently minimizing the need for excessive material usage. Unlike wooden formwork, which often necessitates cutting and shaping the wood to fit the desired structure, steel formwork can be easily adjusted and reused for different projects, thereby reducing material wastage. Moreover, steel formwork yields a smooth and even surface finish, eliminating the necessity for additional material to be used for surface treatments. This eradicates the need for plastering or smoothing out uneven surfaces, which would otherwise require additional materials such as plaster or cement. By providing a high-quality finish directly from the formwork, steel frame formwork minimizes material waste in the form of surface treatments. In summary, steel frame formwork significantly contributes to the reduction of material waste through its reusability, adjustability, and ability to provide a high-quality finish. These attributes enhance the efficiency and sustainability of the construction process, ultimately reducing the overall environmental impact of construction projects.

- Q: What are the different types of formwork clamps used with steel frame formwork systems?

- There are several types of formwork clamps that are commonly used with steel frame formwork systems. These clamps are designed to securely hold the formwork panels together, ensuring stability and accuracy during the concrete pouring process. 1. Wedge clamps: These clamps consist of a wedge-shaped piece that is inserted between the formwork panels and tightened using a hammer. They are easy to install and remove, making them a popular choice for temporary formwork systems. 2. Hook clamps: These clamps have a hook-shaped design that allows them to be easily hooked onto the steel frame. They are typically used in conjunction with wedge clamps to provide additional stability and prevent any movement of the formwork panels. 3. Rapid clamps: These clamps are designed for quick and efficient installation. They have a lever mechanism that allows for easy tightening and releasing of the clamps. Rapid clamps are often used in large-scale construction projects where time is of the essence. 4. Adjustable clamps: These clamps have a flexible design that allows for adjustment to accommodate different sizes of formwork panels. They are particularly useful when working with irregularly shaped or custom-sized formwork. 5. Panel clamps: These clamps are specifically designed to hold the formwork panels together at the edges. They typically have a spring-loaded mechanism that provides a strong grip and ensures that the panels are tightly secured. Overall, the choice of formwork clamps will depend on the specific requirements of the project, such as the size and shape of the formwork panels, the desired level of stability, and the speed of installation. It is important to select the appropriate clamps to ensure the safety and efficiency of the formwork system.

- Q: What are the factors that determine the design of steel frame formwork?

- The design of steel frame formwork is influenced by several factors. Firstly, the specific type and size of the structure being built are key determinants. Different structures, like high-rise buildings, bridges, or industrial facilities, have varying requirements in terms of load-bearing capacity, shape, and dimensions. As a result, the design of the steel frame formwork must be able to accommodate these specific needs. Secondly, the expected concrete pressure on the formwork is another important consideration. This pressure is influenced by factors such as the structure's height, the type of concrete mix used, and the rate of concrete pouring. The design of the steel frame formwork should be able to withstand the anticipated concrete pressure without deforming or collapsing. Thirdly, the construction schedule and project timeline also impact the formwork design. If the construction requires a fast-paced schedule with quick turnaround times, the formwork design should allow for easy assembly, disassembly, and reusability. Conversely, if the project timeline allows for longer construction periods, the design can prioritize durability and longevity. Additionally, factors like budget, availability of materials, and construction site conditions also influence the formwork design. The design should be cost-effective, utilizing readily available materials suitable for the construction site environment. Furthermore, factors like weather conditions, topography, and site accessibility may require additional reinforcements or modifications to ensure stability and safety. Lastly, compliance with local building codes, regulations, and safety standards is of utmost importance. The formwork design should adhere to these guidelines to ensure the structural integrity of the construction and the safety of workers. In conclusion, the design of steel frame formwork is determined by various factors, including the type and size of the structure, expected concrete pressure, construction schedule, budget, availability of materials, construction site conditions, and compliance with building codes and safety standards. A comprehensive understanding of these factors is crucial for creating a formwork system that meets the specific requirements of a construction project.

- Q: How does steel frame formwork accommodate for different concrete pumping methods?

- Steel frame formwork proves to be a versatile and adaptable system capable of effectively accommodating various concrete pumping methods. Its design ensures robustness and stability, facilitating the efficient transfer of forces during the concrete pouring process. A significant advantage of steel frame formwork lies in its ability to withstand the high pressures generated by different concrete pumping methods. Truck-mounted boom pumps, stationary pumps, and line pumps all exert forces during the pumping process, which the steel frame formwork can handle without compromising its structural integrity. Moreover, customization and adjustment options are readily available with steel frame formwork to cater to different concrete pumping methods. The formwork panels can be designed with openings like holes or slots to accommodate pipes and hoses used in the pumping process. This feature ensures smooth and efficient pumping operations, preventing any blockages or hindrances. Additionally, the steel frame formwork system is easily disassembled and reassembled, making it suitable for diverse project requirements and changing pumping methods. This flexibility allows for effortless modifications and adjustments to the formwork system, ensuring it can adapt to any alterations in the concrete pumping method during the construction process. Overall, steel frame formwork proves to be a dependable and adaptable solution for accommodating various concrete pumping methods. Its robust nature, stability, and customization options make it the preferred choice in construction projects where concrete pumping is necessary.

- Q: How does steel frame formwork handle different types of concrete pumping methods?

- Steel frame formwork is versatile and can handle different types of concrete pumping methods effectively. Whether it is the traditional method of pouring concrete manually or using modern techniques like boom pumps or line pumps, steel frame formwork is designed to accommodate various pumping methods. The strong and rigid structure of steel frame formwork ensures stability and prevents any deformation or displacement during the pumping process. It offers a reliable platform for concrete placement, allowing for efficient and smooth pumping regardless of the method used.

- Q: Can steel frame formwork be used for heavy-duty industrial structures?

- Yes, steel frame formwork can be used for heavy-duty industrial structures. Steel frame formwork is a robust and durable system that can withstand the high loads and pressures associated with heavy-duty structures. It offers excellent strength and stability, making it suitable for constructing large-scale industrial buildings, such as warehouses, factories, and power plants. The steel frame formwork system can be customized and adjusted to meet the specific requirements of each project, ensuring the construction of a reliable and sturdy structure. Additionally, steel frame formwork allows for faster construction compared to traditional methods, resulting in cost and time savings for the project.

Send your message to us

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords