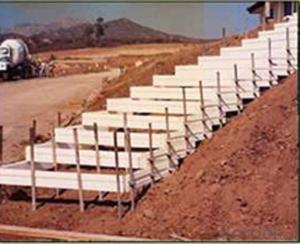

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Circular Column Formwork Outrigger For Scaffolding With New Design

Plastic Formwork Concrete Formwork Circular Column Used Scaffolding Props New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels..

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

FAQ

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: What are the different types of formwork release agents used with steel frame formwork?

- Different types of formwork release agents can be utilized with steel frame formwork to prevent concrete from adhering to the formwork. This allows for easy removal once the concrete has hardened. 1. Petroleum-based release agents are commonly employed and are composed of a mixture of petroleum oils and additives. These agents possess favorable release properties and are easily applied. They are suitable for use on both steel and wooden formwork. 2. Water-based release agents are made from a blend of water and surfactants. They are environmentally-friendly and have a low VOC content. These agents can be employed with steel formwork and provide a satisfactory release surface. 3. Silicone-based release agents are utilized when a higher level of release is necessary. They offer a superior surface finish and can be used with steel formwork. However, they tend to be more expensive compared to petroleum or water-based options. 4. Non-staining release agents are used when a clean and stain-free concrete surface is desired. These agents do not leave any residue on the concrete surface, ensuring a high-quality finish. They are commonly used in architectural applications where the appearance of the concrete is important. 5. Form release papers serve as an alternative to liquid release agents. They are thin, flexible sheets placed between the formwork and the concrete. Form release papers provide an effective release surface and can be used with steel formwork. They are user-friendly and eliminate the need for applying a liquid release agent. When selecting a formwork release agent for steel frame formwork, it is crucial to consider the specific project requirements. Factors such as desired finish, environmental concerns, and cost should be taken into account.

- Q: How does steel frame formwork handle different types of concrete surface cleaning methods?

- Steel frame formwork is highly versatile and can handle different types of concrete surface cleaning methods effectively. The robustness and durability of steel make it resistant to damage caused by various cleaning techniques such as pressure washing, chemical cleaning, or abrasive methods. Additionally, the smooth surface of steel frame formwork allows for easy removal of dirt, stains, and other contaminants, ensuring efficient and thorough cleaning.

- Q: Can steel frame formwork be used for both internal and external concrete walls?

- Yes, steel frame formwork can be used for both internal and external concrete walls. The steel frame provides strength and stability, making it suitable for various construction applications. Additionally, the formwork can be easily adjusted and reused, making it a cost-effective solution for both internal and external walls.

- Q: What are the safety precautions for using steel frame formwork in hazardous conditions?

- When using steel frame formwork in hazardous conditions, it is crucial to take several safety precautions. These precautions include ensuring that all personnel involved are properly trained and equipped with appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and steel-toed boots. Additionally, the formwork should be inspected regularly for any signs of damage or weakness, and any defective components should be replaced immediately. Adequate fall protection systems, such as guardrails and safety nets, should be installed to prevent falls from heights. Lastly, it is important to follow all relevant safety guidelines and regulations specific to the hazardous conditions, such as those related to working in confined spaces or operating heavy machinery.

- Q: How does steel frame formwork accommodate for different concrete pouring rates?

- Steel frame formwork is a versatile system that can easily accommodate different concrete pouring rates. This is primarily achieved by the adjustability and flexibility of the steel frame panels used in the formwork. One of the main features of steel frame formwork is its modular design. The panels can be easily assembled and disassembled, allowing for quick adjustments to the formwork configuration. This means that if a faster concrete pouring rate is required, additional panels can be added to the formwork system to increase the pouring area, ensuring that the concrete can be poured at a higher rate without compromising the structure's integrity. Furthermore, the steel frame panels can be adjusted in height and width, providing further adaptability to accommodate different pouring rates. By adjusting the formwork's dimensions, the volume of concrete that can be poured in a given amount of time can be increased or decreased as needed. This flexibility is especially important in cases where the concrete needs to be poured at varying rates due to different sections of the structure requiring different curing times. In addition to the adjustability of the formwork panels, steel frame formwork also allows for the use of various accessories and supports. These accessories, such as adjustable props and braces, can be used to reinforce the formwork system and provide additional support to handle higher pouring rates. By strategically placing these accessories, the formwork can withstand the pressure exerted by the concrete and ensure that it remains stable during the pouring process. Overall, steel frame formwork is designed to be adaptable and flexible, enabling it to accommodate different concrete pouring rates. Its modular design, adjustable panels, and the use of supporting accessories make it a suitable choice for various construction projects where pouring rates may vary.

- Q: What is the lifespan of a steel frame formwork system?

- The duration of a steel frame formwork system's lifespan can differ based on various factors. Typically, a properly maintained and utilized steel frame formwork system can endure for several years, typically spanning from 10 to 20 years. Nevertheless, it is important to acknowledge that the duration can be influenced by several factors, including the caliber of materials employed, the frequency of usage, the level of maintenance and repairs, and the nature of the construction projects it is employed for. To extend the lifespan of the formwork system, regular inspections and maintenance are vital. This entails examining for indications of deterioration, corrosion, or damage and promptly addressing any problems that arise. Proper cleaning, lubrication, and storage also significantly contribute to preserving the steel frame formwork system's lifespan. Furthermore, the type of construction projects it is utilized for can impact its lifespan. Heavy-duty projects involving frequent usage and rough handling may result in accelerated wear and tear compared to lighter projects with less frequent usage. In conclusion, the lifespan of a steel frame formwork system can range from 10 to 20 years; however, this can fluctuate depending on factors such as maintenance, material quality, frequency of usage, and construction project type.

- Q: How does steel frame formwork affect the overall insulation of a structure?

- The overall insulation of a structure is not directly impacted by steel frame formwork. The materials used for the walls, roofs, and floors, as well as the installation techniques employed, primarily determine the insulation of a building. On the other hand, steel frame formwork is a temporary structure used during construction to mold and shape concrete. It provides a robust and stable support system for the concrete until it cures and gains strength. Although steel frame formwork itself does not directly affect insulation, it can indirectly influence it in a few ways. In colder climates, the presence of steel frame formwork may necessitate additional insulation measures during the construction phase to prevent heat loss. This could involve using temporary insulation materials or heating systems to maintain a suitable temperature for the curing process. Moreover, the installation of steel frame formwork may create penetrations or voids in the concrete structure, which, if not properly addressed, could compromise insulation. These penetrations or voids can create thermal bridges that allow heat to escape or enter the structure, thereby reducing overall energy efficiency. Therefore, it is crucial to carefully seal and insulate any openings or gaps created during the installation of the formwork to maintain an effective insulation barrier. To summarize, the overall insulation of a structure is not directly impacted by steel frame formwork. However, it can indirectly affect insulation requirements and contribute to thermal bridging if not properly addressed. It is essential to consider insulation strategies and take appropriate measures during the construction phase to ensure a well-insulated and energy-efficient building.

- Q: Does steel frame formwork require any special equipment for installation and removal?

- Special equipment is needed for the installation and removal of steel frame formwork. Cranes or hoists are often necessary to lift and position the steel frames. In addition, specialized tools like wrenches and spanners may be necessary to tighten the bolts and ensure a secure connection between the frames. To remove the steel frame formwork, cranes or hoists are also necessary to safely lift and remove the frames from the structure. In conclusion, proper equipment is essential to ensure the efficient and safe installation and removal of steel frame formwork.

- Q: Can steel frame formwork be used for pre-stressed or post-tensioned concrete structures?

- No, steel frame formwork cannot be used for pre-stressed or post-tensioned concrete structures. Pre-stressed or post-tensioned concrete structures require specialized formwork systems that can handle the high tension forces generated by the pre-stressing or post-tensioning process. Steel frame formwork is not designed to withstand these forces and may fail, leading to a potential collapse of the structure. It is essential to use formwork systems specifically designed and engineered for pre-stressed or post-tensioned concrete structures to ensure the safety and integrity of the construction project.

- Q: Can steel frame formwork be used in projects with high architectural finish requirements?

- Projects with high architectural finish requirements can indeed make use of steel frame formwork. The utilization of steel frame formwork guarantees a remarkable level of accuracy and stability, thereby ensuring a uniform and precise architectural finish. This is of utmost importance in achieving a smooth and flawless end result. The steel frames can be easily adjusted and tailored to fit various shapes, curves, and angles, thereby accommodating intricate and complex architectural designs. Furthermore, steel frame formwork exhibits exceptional durability and is able to withstand the immense pressure exerted by the concrete during the pouring process. This ensures that the formwork remains intact and maintains its shape throughout the construction process. In conclusion, steel frame formwork is a dependable and adaptable choice that can fulfill the high architectural finish requirements of diverse construction projects.

Send your message to us

Concrete Slab Formwork Scaffolding System Formwork Iron Scaffolding High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords