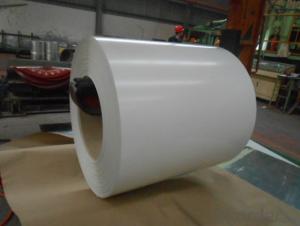

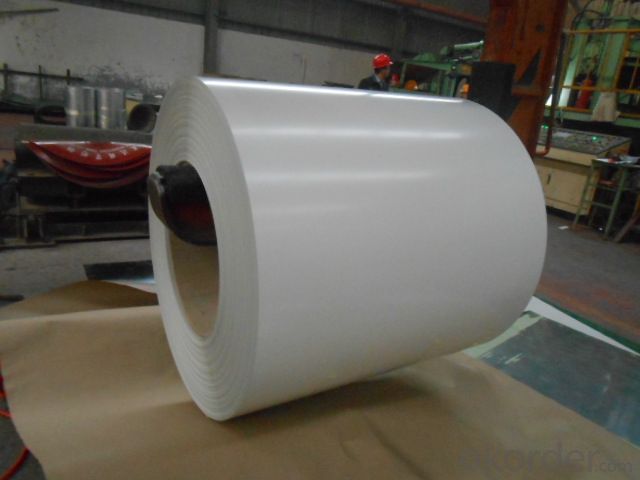

Color pre- painted galvanized steel in coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color pre-painted steel in coil

The prepainted steel sheets are mainly provided for various commercial purposes covering architectural construction, electrical household appliances, transportation, etc.

The structure of prepainted steel includes finished coating, primer coating, chemical conversion coating metallic coating and cold-rolled steel.

Pattern: can be customized according to customers requirements.

Suitable for indoor or outdoor decoration, color lasting for at least 10 years for outdoor using, could for roll forming.

Protective film can be provided according to customer needs.

Paint: PE or PVDF

Width and Thickness: width within 1250mm, thickness from 0.23-0.8

Color pre painted steel in coil

ZINC COATING:G30

TOP COATING:5 MIC EPOXY+20 MIC PE, PROTECTION FILM

BACK COATING: 7 MIC EPOXY GREY

WEIGHT PER COIL:3-5 TONS COLOR: RAL 9010 PURE WHITE

STANDARD:JIS G3312,CGCC

SIZE:0.35*1200MM*C

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- definitely steel. i used to hit bullseyes with a good slingshot, and you need heavy, perfectly spherical small steel shot. smaller than a marble, bigger than a bb.

- Q: How are steel coils used in the production of gutters and downspouts?

- Steel coils are used in the production of gutters and downspouts as they are uncoiled and fed into a roll-forming machine. This machine shapes and cuts the steel into the desired gutter or downspout profiles. The steel coils provide the necessary raw material for creating durable and long-lasting gutters and downspouts that effectively channel rainwater away from buildings.

- Q: What are the different types of steel coil packaging?

- There are several types of steel coil packaging, including steel strapping, stretch wrapping, shrink wrapping, and wooden crates.

- Q: I've seen on TV that stainless steel laminate sheets can be purchased and and used to cover appliances to give it a faux stainless steel look. They mentioned it was important to not have any bubbles (of course) and to work slowly. It's easy to do on a dishwasher, but what about the fridge? The handles are in the way? Do you have to take the handles off? Can anyone find a tutorial for me?

- There okorder appliance paint 2. What you are referring to really is not laminate steel sheets, it's actually more along the lines of shelf liner paper looks like steel with sticky back film that you peel and stick. Place against product and begin to peel down slowly using squeegee or credit card to smooth out bubbles.Sheets can be purchased rangingin size on OKorder for $9.99 + dependent on size. Called stainless steel appliance film can buy a roll for $60.00 on OKorder (normally sells for $100.00) one roll will cover 3 average sized kitchen appliances. Hope this helps!

- Q: How are steel coils inspected for paint adhesion using adhesion testers?

- Paint adhesion on steel coils is systematically and rigorously inspected using adhesion testers. These testers are specifically designed devices for assessing the bond strength between the paint and the underlying steel surface. To begin the inspection process, representative samples are selected from the steel coils. These samples are typically cut into smaller sections to ensure they are free from defects or surface irregularities that could impact the adhesion test results. Once the samples are prepared, the adhesion testers are utilized to measure the force needed to detach the paint coating from the steel surface. The most commonly used adhesion tester is the cross-cut adhesion tester. It consists of a set of blades arranged in a grid pattern, which are employed to create cuts through the paint coating, forming a grid of squares or rectangles down to the steel surface. After the cuts are made, a specialized tape is applied to the grid area and pressed firmly onto the surface. The tape is then rapidly pulled off at a 90-degree angle to the surface, and the force required for the paint coating's removal from the steel is measured and recorded. The results of the adhesion test are evaluated based on predetermined standards or specifications. These standards typically define the minimum acceptable adhesion strength for the specific application or industry. If the measured adhesion strength falls below the specified threshold, it indicates poor paint adhesion, which could result in issues like paint delamination or corrosion. Along with the cross-cut adhesion tester, other adhesion testing methods may also be utilized, such as the pull-off adhesion tester. This method involves a hydraulic or mechanical device applying a tensile force to a small circular or dolly-shaped test area. The force required to pull off the dolly is measured and used to assess the paint adhesion. In summary, the use of adhesion testers ensures a thorough inspection of paint adhesion on steel coils. This process helps in early identification of potential adhesion issues, enabling appropriate remedial measures to be taken to ensure the durability and performance of the paint coating.

- Q: Please people suggest me how can I select external finishing for Steel Building as there is a wide range of choice available.

- Nowadays, okorder /

- Q: How are steel coils coated to prevent corrosion?

- Steel coils are often coated to prevent corrosion through a process called galvanization. This involves applying a layer of zinc to the surface of the steel coils, which acts as a protective barrier against moisture and other environmental elements. The zinc coating effectively prevents rust and corrosion from forming on the steel surface, extending the lifespan of the coils.

- Q: Im looking to learn guitar and i was wondering if steel strings are too hard to use as a beginner. I am also self teaching so any good lesson books/starting guitar recommendations are welcome !! thanks.

- Steel strings are fine for a beginner. I learned to play on Steel strings and I have always preferred them to nylon strings.

- Q: not iron, steel

- steel was first used in the 1800s in buildings.

- Q: what is the porpose of preheating mild steel prior to welding

- ok dont listen to bob the builder down there, u preheat thicker steels to draw moisture out of them. take a propane torch to something exposed to just atmospheric air around 3 inches thick and the water will literally pour out of it. do u want that in ur weld? no. so u preheat to draw any moisture or contaminates out of the base metal. good luck.

Send your message to us

Color pre- painted galvanized steel in coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords