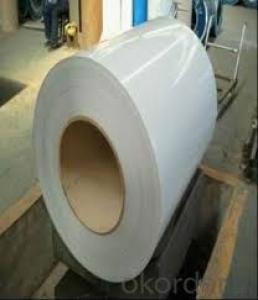

Pre Painted Galvanized Steel Colored Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

PPGI-Pre-painted galvanised iron is also known as pre-coated steel, typically with a hot dip zinc coated steel substrate.

Hot-dip galvanizing deposits a thick robust layer that may be excessive. In the case of automobile bodies, where additional rust proofing paint will be applied, a thinner form of galvanizing is applied by electrogalvanization. The hot-dip process generally does not reduce strength on a measurable scale, with the exception of high-strength steels where hydrogen embrittlement can become a problem.[4][5] this is a consideration for the manufacture of wire rope and other highly stressed products. The protection provided by hot dip galvanizing is insufficient for products that will be constantly exposed to corrosive materials such as salt water.

Application:

Suitable for indoor or outdoor decoration, color lasting for at least 10 years for outdoor using, could for roll forming., conditioning, micro-wave oven, bread maker,solar water heater,condencing apparatus,Blackboard, white board,chalkboard, hidden cell blackboard,bulletin board,Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf,garbage can, billboard, typewriter, instrument panel, weight sensor, photographic equipment,coffin, fence, Prepainted Galvanized Steel Coil

Product Specification:

Paint: PE or PVDF

Color pre painted steel in coil

Thickness: 0.3-0.8mm

Width: 914-1250mm

Inner Diameter: 508mm,610MM

Weight of Steel Coil: 3-8MT

Available Dipped Layer: 50-150g/m2

Coating Type: Al-Zn Alloy

Front Side Paint Thickness: 15-25μm

Back Side Paint Thickness: 5-10μm

Standard:JIS G3312,CGCC

FAQ:

1.How about the color of the Pre Painted Steel Coil

The color of the Pre Painted Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue.

2.Can you produce the goods according to the customer’s requirements?

Yes, of course, it can be customized according to customers requirements.

3.Could you tell me the package for the Pre Painted Steel Coil?

Usually Standard export seaworthy package: waterproof paper+steel trip packed+wooden case seaworthy package

- Q: What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include a protective zinc coating that prevents corrosion, high strength and durability, excellent formability and weldability, and a smooth and shiny surface finish.

- Q: How are steel coils processed and treated?

- To ensure the quality and suitability of steel coils for different applications, they undergo a series of steps and treatments. Initially, the coil is uncoiled by removing its protective wrapping and unwinding it. Any defects like cracks or uneven surfaces are then inspected. Next, the coil is cleaned to eliminate dirt, oil, and rust using chemical agents and mechanical scrubbing. After cleaning, it is rinsed and dried to prevent corrosion caused by residual moisture. Once cleaned, the steel coil may be treated based on its intended use. One common treatment is pickling, where the coil is immersed in an acidic solution to remove impurities and scale. This improves the surface finish and prepares the steel for further processing. After pickling, the coil can undergo cold rolling, which reduces its thickness and improves dimensional accuracy. This is done by passing the steel through a series of rollers at room temperature, gradually decreasing thickness and increasing strength. It also improves the surface finish. In some cases, the coil may undergo additional heat treatments like annealing or tempering. Annealing involves heating the coil to a specific temperature and slowly cooling it to relieve internal stresses and improve mechanical properties. Tempering, on the other hand, involves reheating the coil to a lower temperature and rapidly cooling it to enhance strength and toughness. Once the desired processing and treatments are completed, the steel coil may be coated or painted for added protection against corrosion or to enhance its appearance. Coating processes can include hot-dip galvanizing, electroplating, or applying organic coatings like paint or powder coatings. Finally, the processed and treated steel coils are cut into specific sizes or shapes according to customer requirements. This can be done using cutting methods such as shearing, slitting, or sawing. Overall, the processing and treatment of steel coils involve cleaning, pickling, rolling, heat treatment, coating, and cutting processes. These steps are carefully carried out to ensure the quality, strength, and suitability of the steel for its intended applications.

- Q: What is the major disadvantage of hardened steel? Do you think this form of iron would be wear resistant and retain a sharpened edge?

- a disadvantage is the fact that the cold forming capability of this steel

- Q: Can i use steel shot in a remington 870 wingmaster full choke 30 inch barrel. the shotgun is in great shape and about 20 or 25 years old probably. thank you. the steel shot i have got is 12 gauge 2 3/4 in 1550 velocity 1 1/16 oz 2 shot winchester xpert high velocity steel shot

- The biggest problem is the FULL choke on the end of the barrel. Steel pellets are harder than lead, so they find it hard to squeeze through the tight full choke. If you do it, you WILL either bulge or crack the muzzle end of the barrel. That is a fact. Newer model 870 shotguns with RemChokes can fire steel, but you have to use a lead MODIFIED choke to send a full pattern down range. Again, for the same reason I mentioned earlier - that the steel does not deform and squeeze itself through the tighter chokes as well. See photo link below at what your barrel will look like after a box of steel shot.

- Q: What is the process of galvanizing steel coils?

- The process of galvanizing steel coils involves several steps to enhance their durability and protect them from corrosion. Firstly, the steel coils are cleaned thoroughly to remove any dirt, oil, or other impurities that may be present on the surface. This is done through an acid pickling process, where the coils are immersed in a bath of diluted acid solution or treated with a chemical cleaner. This step ensures that the surface of the coils is free from any contaminants, allowing for better adhesion of the zinc coating. After the cleaning process, the coils are rinsed to remove any remaining acid or cleaner. This is crucial to prevent any adverse reactions with the next step of the process. The next step is the actual galvanization, where the cleaned coils are dipped into a bath of molten zinc. The coils are carefully passed through the zinc bath using rollers or other mechanisms to ensure that the entire surface is coated evenly. The zinc bath is maintained at a specific temperature, typically around 450°C (842°F), which allows the molten zinc to bond with the steel surface. As the coils are withdrawn from the zinc bath, excess zinc is removed by passing them through air knives or by centrifugal spinning. This helps to control the thickness of the zinc coating and ensure a uniform appearance. Once the galvanization process is complete, the steel coils are cooled down gradually to room temperature. This allows the zinc coating to solidify and bond firmly with the steel surface, creating a protective barrier against corrosion. The final step in the process is inspection and quality control. The galvanized steel coils are inspected for any defects, such as uneven coating or areas with insufficient zinc coverage. This is usually done visually or through specialized equipment that can detect any anomalies. Additionally, the coating thickness is measured to ensure it meets the required specifications. Overall, the process of galvanizing steel coils is designed to enhance their longevity and protect them from rust and corrosion. By applying a layer of zinc coating to the steel surface, the coils become more resistant to environmental factors, making them suitable for a wide range of applications in various industries.

- Q: How are steel coils processed and shaped into different products?

- Steel coils are processed and shaped into different products through a series of manufacturing techniques. First, the coils are uncoiled and straightened to remove any deformities. Then, they go through processes like cutting, slitting, or shearing to achieve the desired width and length. Next, the steel is shaped using techniques like rolling, bending, or stamping to create specific profiles, such as sheets, plates, or tubes. Additionally, various heat treatments and surface finishes can be applied to enhance the strength, durability, and appearance of the steel products. Overall, a combination of mechanical, thermal, and chemical processes is employed to transform steel coils into the wide range of products we see in industries like construction, automotive, and manufacturing.

- Q: I am searching for an online article which discusses any aspect of the use of austenitic stainless steels. I was just wondering if anyone could help me find one. No sales articles. Thank you!

- *Austenitic, okorder

- Q: so why shouldn't one use a steel cased 223 in an ar15?

- Because some people ***** and moan about how the lacquer or polymer gums up the chamber causing torn case rims. But they don't clean there guns anyway so there point is irrelevant. Some say it wears out your extractor faster which is also bullshit. The steel casings are a milder bi-metal. Really its people complaining for the sake of complaining.

- Q: I need help my new stainless steel cookware is sticking ? My first meal was nasty!

- You sure it's stainless steel? Quick test, is to put a magnet to it. Stainless steel won't stick to a magnet,Sorry your meal turned out icky. Bye

- Q: I'm looking for steel to make knives, but don't know what to get.

- If you are serious about making knives, I'd highly recommend visiting one of the many knifemaking forums. As usual they have good FAQs and could be good source of info, equipment and materials, let alone advices from fellow makers.

Send your message to us

Pre Painted Galvanized Steel Colored Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords