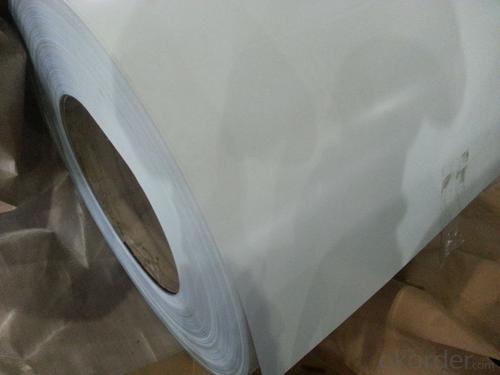

PRE-PAINTED GALVANIZED STEEL IN COILS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRE-PAINTED GALVANIZED STEEL IN COILS

TOP COATING :5+13 PE,

BACK:5-7 MICRONS,EPOXY ZINC COATING:60g/m2 ( +/-10g/m2)

WEIGHT PER COIL:3-6tons COIL INNER DIAMETER:508mm

STANDARD:JIS G 3312 CGCC

SIZE: 0.30mm*1000mm*C

RED/GREEN/BLUE/BLACK/WHITE COLOR

Package:Standard export seaworthy package:waterproof paper+steel trip packed+wooden case seaworthy package

The color of the Pre Painted Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue.

Pre Painted Steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

The base metals for Pre Painted Steel Coil consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Pre Painted Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

The Pre Painted Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

- Q: What are the different coil cutting methods used for steel coils?

- There are several different coil cutting methods used for steel coils, including slitting, shearing, and laser cutting. Slitting involves using circular blades to cut the coil into narrower strips. Shearing involves using straight blades to cut the coil into desired lengths or shapes. Laser cutting, on the other hand, uses a high-powered laser beam to precisely cut the steel coil into specific shapes or patterns. Each method offers its own advantages and is chosen based on the desired outcome and requirements of the steel coil cutting process.

- Q: What are the different types of steel coil surface defects?

- During the manufacturing or handling process, various steel coil surface defects may arise. Some commonly encountered types are as follows: 1. Rust: When moisture or oxygen comes in contact with the steel coil, rust, a reddish-brown discoloration, may develop on its surface. 2. Scratches: While the steel coil is being handled or transported, superficial marks known as scratches can be incurred. These marks can vary in depth and severity, ranging from light surface scratches to deep gouges. 3. Stains: Exposure to chemicals or other substances can lead to stains, discolored patches that appear on the coil's surface. Removing them may prove to be challenging. 4. Roll marks: During the rolling process, impressions or indentations called roll marks may form. Uneven pressure or misalignment of the rolls causes them, resulting in lines or patterns on the coil's surface. 5. Edge wave: Imperfectly flat edges of the coil can result in a defect known as edge wave. This defect causes the edges to appear wavy or uneven and can impact the coil's overall appearance and performance. 6. Oil spots: If the oil or lubricants utilized in the manufacturing process are not adequately removed, surface defects called oil spots can manifest. These spots appear as dark patches or spots on the coil's surface and may hinder the adhesion of coatings or paints. 7. Pitting: Small, shallow depressions or pits on the coil's surface are indicative of a defect called pitting. Factors like corrosion, uneven cooling, or impurities in the steel can cause this defect. 8. Holes: Holes are severe surface defects that can arise due to various factors, including corrosion, mechanical damage, or manufacturing errors. These defects come in different sizes and can significantly compromise the coil's structural integrity. Promptly addressing these surface defects is crucial for maintaining the quality and performance of the steel coil. Regular inspections, proper handling, and appropriate surface treatments can help minimize the occurrence of these defects.

- Q: What are the dimensions of steel coils?

- The dimensions of steel coils can vary depending on the specific product and application, but they typically range in thickness from 0.005 to 0.25 inches and in width from 0.5 to 72 inches. The length of steel coils can also vary, but it is commonly around 100 to 200 feet.

- Q: At what temperature does steel start to warp or soften.

- It depends upon the composition of steel. Carbon steel, which does not have many alloying elements, softens around 1200C while with alloying elements, this transition temperature either drops or raises depending upon what is added. Higher carbon makes this temperature drop. This is a very important question for forging since if a lower temperature is used, forging won't be easy and at higher than softening temperature, it is not easy to handle. The temperature at which steel begins to soften is, in general, much above what the metallurgists call AC1 or AC3 temperature.

- Q: What is the standard thickness of steel coils?

- The standard thickness of steel coils can vary depending on the specific application and industry. However, common thickness ranges for steel coils typically fall between 0.015 inches (0.38 mm) and 0.125 inches (3.17 mm).

- Q: How are steel coils used in appliances?

- Steel coils are commonly used in appliances as a key component in the manufacturing of various parts such as heating elements, motors, compressors, and springs. These coils provide durability, strength, and flexibility to ensure the efficient functioning of appliances like refrigerators, washing machines, air conditioners, and stoves.

- Q: I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

- Q: I like steel strings but don't want to get a new guitar. Is that my only option?

- Don't EVER put steel strings on a nylon stringed guitar. Steel strings have many times more tension than nylon strings. The bodies on nylon stringed guitars are braced lighter than their steel stringed cousins. If you put steel strings on a guitar designed for nylon, they will belly the top up as well as warp the neck. Since they're attached differently, you'd (luckily) have a hard time even getting steel strings to fit. Enjoy your nylon string guitar for what it is, and if you want to play steel strings, buy a guitar designed for them.

- Q: Will a 8mm steel ball fired from a 150lbs crossbow kill small game and if so, from how many yards?

- An 8mm steel ball fired from a 150# crossbow is probably going to damage your crossbow. Crossbows shoot arrows (or bolts), NOT ball bearings and, furthermore, a 150# crossbow needs an arrow (or bolt) of about 450 grains in order to be efficient and operate without damaging itself. A 450 grain arrow will kill small game very well and out to a range of about 30 yards. Don't wind up like the guy below... EDIT: Racing Pace Stick - I stand corrected. There are, indeed, tacticool crossbows that shoot ball bearings and they all seem to come straight from Shandong Province, China. Note that these are not implements suited to hunting. Also note that if you shoot an 8mm steel ball out of a 150# draw compound crossbow that IS suitable for hunting, you are probably going to break it.

- Q: How do steel coils contribute to the packaging industry?

- Steel coils play a crucial role in the packaging industry by providing a durable and versatile material for packaging various products. The use of steel coils in packaging ensures the protection and preservation of goods during transportation and storage. One way steel coils contribute to the packaging industry is through their strength and durability. Steel is known for its high strength-to-weight ratio, making it an ideal material for packaging heavy and bulky items. Steel coils can withstand significant pressure and impact, ensuring that goods remain intact and undamaged throughout the supply chain. This strength also allows for the stacking of packages, optimizing storage space and reducing the risk of damage. Furthermore, steel coils are highly resistant to corrosion and moisture. This property is particularly important in the packaging industry as it helps protect goods from environmental factors that could potentially compromise their quality. Steel coils can be coated or treated to enhance their corrosion resistance, ensuring that packaged products remain in pristine condition. Steel coils are also versatile and can be easily customized to suit specific packaging requirements. They can be cut and shaped into various forms, such as sheets, straps, or bands, to secure and protect different types of products. Additionally, steel coils can be easily integrated with other packaging materials, such as cardboard or plastic, to provide added strength and stability. Another benefit of steel coils in the packaging industry is their recyclability. Steel is one of the most recycled materials globally, and steel coils can be easily recycled and reused. This sustainability aspect makes steel coils an environmentally friendly choice for packaging, contributing to the reduction of waste and the conservation of resources. In summary, steel coils play a vital role in the packaging industry by offering strength, durability, corrosion resistance, versatility, and recyclability. Their use ensures the safe transport and storage of goods, providing a reliable and sustainable packaging solution for a wide range of industries.

Send your message to us

PRE-PAINTED GALVANIZED STEEL IN COILS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords