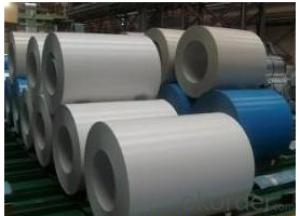

Color Coated Steel Coils/ Pre-painted Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Galvanized steel coil features:

. Zinc coating :40-275g( as required)

. thickness:0.17-1.2mm

. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

. Coil id:508m610mm

. Coil weight: 3-12(as required)

. Surface treatment: cremated, oiled, skin passed

. Spangle: regular,small, zero

2. Application of Galvanized steel coil features

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

3.Painting colour steel , zinc coated steel , lead coated steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.2mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: |

building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

price: | favorable price | Our Customers | Steel force, Stemcor, Duferco, Samsung , G&G,Hyosung,CNBM |

4.Painting colour steel image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Hi I was thinking about buying this knife, but i wasn't sure if it was good because it's stainless steel.

- This isn't really a question for this section, but I'm still happy to help out since I'm a big cutlery nerd as well. One thing to look out for when buying a knife is a lack of specifics on what steel is being used. High Carbon Stainless Steel doesn't tell you what the steel is, just what it MIGHT be. Chances are it's something along the lines of 420HC or 440A, both of which are softer steels. They aren't the worst steels around, but they are very quick to dull. You'd be better off looking at the Balisongs of Benchmade. They'll cost more, but you'll know that you're getting something made with quality materials and that won't break on you. And if it does break for some odd reason, Benchmade's warranty and customer service are both fantastic. Although if a more questionable knife is okay with you as long as the price isn't too high, then at least 420HC and 440A aren't too brittle and will take a decent edge even though they'll dull quickly. As for whether stainless steel is good for a knife or not, that depends on the type of stainless steel and what you're going to use the knife for. Many stainless steels are more brittle than a carbon steel, so high carbon stainless steels are a bit more likely to rust but a little tougher as well. In a butterfly knife, a steel like that is a good way to go, although the steels used by Benchmade, as I mentioned, are of a much better quality.

- Q: I should have known, but magnets don't stick to stainless steel, so now I'm at a loss, I can't display my photos on the fridge. any ideas?

- An Italian theme would be great for that or just sleek clean lines with the colors stainless steal, red, and accented with black. I like that personally. But it is up to you and what you like and don't like. You could also go an Asian theme. That would be pretty. Asian stuff seems to lean toward reds, greens, and neutrals.

- Q: How are steel coils inspected for thickness and width accuracy?

- Steel coils are inspected for thickness and width accuracy using non-destructive testing methods such as ultrasonic testing and laser measurement systems. Ultrasonic testing involves sending high-frequency sound waves through the coil, and by analyzing the reflected waves, the thickness of the steel can be determined. Laser measurement systems use lasers to scan the width of the coil, providing precise measurements. These inspection methods help ensure that steel coils meet the required thickness and width specifications.

- Q: How do steel coils contribute to the energy sector?

- Various contributions are made by steel coils to the energy sector. Firstly, they play a crucial role in the manufacturing of essential equipment and infrastructure for energy production and distribution. Examples include power plants, transmission towers, and pipelines. These structures necessitate robust and durable materials, which are provided by steel coils, ensuring the required strength and reliability. Additionally, steel coils have a significant impact on the renewable energy sector. They are utilized in the production of wind turbines and solar panels. For wind turbines, steel coils are necessary for constructing the towers, while solar panels rely on steel frames for support and durability. With the increasing demand for renewable energy sources, the utilization of steel coils in this sector is expected to rise correspondingly. Moreover, steel coils are integral in the manufacturing of electrical transformers. Transformers are vital components in the energy sector as they facilitate the transmission and distribution of electricity. The core of the transformer, responsible for efficient energy transfer, is created using steel coils. The quality and dependability of the steel coils used in transformers are crucial to ensure the smooth functioning of the electrical grid. In addition to their direct applications, steel coils also indirectly contribute to the energy sector. Steel is a recyclable material, and the recycling process consumes less energy compared to the production of new steel. By employing recycled steel coils, the energy sector can decrease its carbon footprint and contribute to a more sustainable and environmentally friendly energy production process. In summary, steel coils are an indispensable component in the energy sector. They are utilized in manufacturing equipment and infrastructure, including power plants, transmission towers, wind turbines, solar panels, and electrical transformers. Furthermore, the recyclability of steel enhances the sustainability of the energy sector.

- Q: What are the different certifications required for steel coil manufacturers?

- Some of the different certifications required for steel coil manufacturers include ISO 9001, ISO 14001, OHSAS 18001, and various industry-specific certifications such as the American Society for Testing and Materials (ASTM) certifications. These certifications ensure that the steel coil manufacturers meet quality, environmental, and occupational health and safety standards.

- Q: I have two guitars, a nylon stringed classical, and a steel stringed acoustic, I find the nylon strings easier to play, but doesn't have as good of sound as the steel stringed, and when I play with the steel strings, it really hurts my fingers, and if I play just a little bit, it feels like the high e string is going to cut my finger. Are the strings too high? What can I do to make the steel strings easier to play?

- If you want to end up playing acoustic steel string, continue learning on that one. Yes, it will hurt, but that's normal and your fingers will toughen up within a couple of weeks of playing (if you play on a regular basis). You will develop callouses. Also, go take your guitar to a shop to get a set up and they will fix the action if it's too high. (Too high action makes the guitar harder to play). When I started playing, at first my fingers *HURT*, but now they don't anymore, even the pinky. :D

- Q: As we all know Shaq killed the movie Steel by suckin so bad but does anyone know what happened to the comic book version.

- The comic book has been long cancelled. You can see Steel in the ongoing 52 miniseries.

- Q: Explain why a steel nail sinks but a steel ship floats.

- Its all about dispersing.weigh and mass. Over a larger area .And the surface tention of the water.A piece of glass will float as long as the water is calm. and doesn't break over the edge of the glass. I don't remember the formula. been away from school to long.

- Q: What are the different steel coil packaging methods?

- There are several different steel coil packaging methods, including using steel strapping or banding to secure the coils, using plastic or metal end caps to protect the edges of the coils, and using wooden or steel pallets to stack and transport the coils. Additionally, some steel coils may be wrapped in protective film or paper to prevent damage during shipping and storage.

- Q: How are steel coils used in the production of solar panels?

- Steel coils are not directly used in the production of solar panels. However, steel may be used as a component in the structural framework or mounting systems of solar panels to provide stability and support.

Send your message to us

Color Coated Steel Coils/ Pre-painted Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords