Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

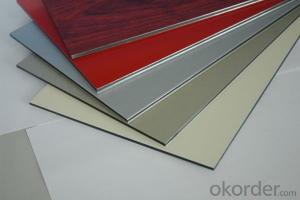

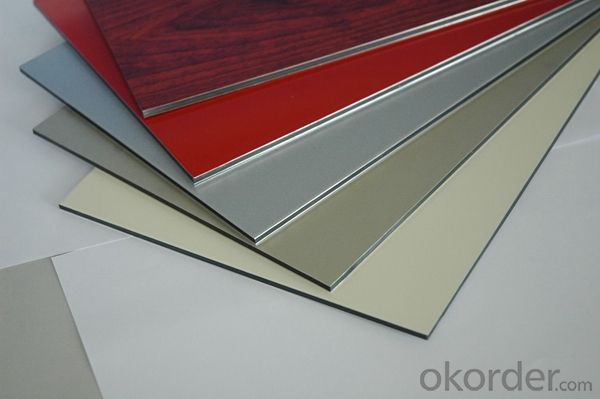

5. Image of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

6. Package and shipping of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: do recycling centers take already compacted aluminum cans? Link is below. if not then why are so many people making homemade can crushers?

- As okorder /... Granted it's controversial but it's not a risk I'm willing to take.

- Q: Which kind of glue is best for bonding aluminum sheets?

- 502 or universal glue

- Q: Can aluminum sheets be used in the aerospace industry?

- Indeed, the aerospace industry does employ aluminum sheets. Aluminum, being a lightweight material with a remarkable strength-to-weight ratio, is highly favored for numerous aerospace purposes. Its usage is prevalent in the manufacturing of aircraft structures, including fuselages, wings, and panels. The adoption of aluminum sheets in the aerospace sector offers several advantages, encompassing diminished fuel consumption due to weight reduction, enhanced maneuverability, and heightened payload capacity. Furthermore, aluminum showcases excellent resistance to corrosion, a vital trait for aircraft operating in harsh environmental conditions. All in all, the aerospace industry extensively relies on aluminum sheets, owing to their advantageous properties and exceptional performance.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: Can aluminum sheets be used for water tanks?

- Water tanks can indeed utilize aluminum sheets. Thanks to its lightweight nature and resistance to corrosion, aluminum is an ideal material for water storage. Its durability and ability to fend off rust and corrosion have made it a popular choice in industries like aerospace and marine. Furthermore, aluminum tanks are simpler to transport and install in comparison to alternative materials, and they can endure high pressure and extreme temperatures. Nonetheless, it is crucial to guarantee that the aluminum sheets employed for water tanks are of exceptional quality and adhere to the required standards to uphold the tank's safety and longevity.

- Q: Can aluminum sheets be used for heat dissipation?

- Yes, aluminum sheets can be used for heat dissipation. Aluminum is known for its excellent thermal conductivity, which allows it to efficiently transfer heat away from a source. This makes it a popular choice for heat sinks and heat exchangers in various industries. Aluminum sheets can be shaped and formed into different configurations to maximize surface area and enhance heat dissipation. The lightweight and corrosion-resistant nature of aluminum also make it a preferred material for heat dissipation applications.

- Q: How is the thickness of an aluminum sheet measured?

- Various methods can be employed to measure the thickness of an aluminum sheet. One commonly used technique involves the utilization of precision measuring tools like a micrometer or caliper. By placing the micrometer on one end of the sheet and gradually closing it until it reaches the other end, an accurate measurement of the thickness can be obtained. This particular method is suitable for thin aluminum sheets. For thicker sheets, a thickness gauge can be utilized. This gauge consists of a compact handheld device equipped with a probe that is pressed against the surface of the sheet. The gauge then displays the thickness reading on a screen. This approach proves especially advantageous when measuring thicker sheets as a micrometer or caliper may not be feasible. An alternative means of measuring the thickness of an aluminum sheet involves the use of an ultrasonic thickness gauge. This tool emits ultrasonic waves from a transducer, which are subsequently reflected back from the surface of the sheet. By calculating the time taken for the waves to travel and return, the gauge can determine the thickness of the sheet with great accuracy. This method is particularly effective for measuring the thickness of large or irregularly shaped aluminum sheets. To summarize, the thickness of an aluminum sheet can be determined using a variety of tools such as a micrometer, caliper, thickness gauge, or ultrasonic thickness gauge, depending on the thickness and size of the sheet.

- Q: Can 101 aluminum sheets be purchased in small quantities or only in bulk?

- Aluminum sheets can typically be purchased in both small quantities and bulk, depending on the supplier and their policies. It is advisable to check with the specific supplier to determine the availability of purchasing 101 aluminum sheets in small quantities.

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is widely used in the aviation industry due to its excellent strength-to-weight ratio, which makes it ideal for constructing lightweight yet strong aircraft structures. Aluminum sheets are commonly used for aircraft panels because they offer a combination of durability, corrosion resistance, and ease of fabrication. Additionally, aluminum can be easily formed and welded, allowing for complex panel shapes to be created. Furthermore, aluminum has good electrical conductivity, which is important for the proper functioning of various aircraft systems. Overall, the use of aluminum sheets for aircraft panels helps to ensure the structural integrity and performance of the aircraft.

- Q: What are the safety precautions when working with aluminum sheet?

- When working with aluminum sheet, it is important to take certain safety precautions. These include wearing personal protective equipment such as gloves, safety glasses, and a dust mask to protect against potential hazards. It is also advisable to work in a well-ventilated area to avoid inhaling any fumes or dust particles. Additionally, using appropriate tools and machinery specifically designed for handling aluminum sheets is essential to prevent accidents or injuries. Finally, proper handling and storage of aluminum sheets, ensuring they are stacked securely and avoiding any sharp edges, can help minimize the risk of accidents or damage.

Send your message to us

Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords