Aluminum Sheets New York - Aluminium Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Sheet Plate AA3003 for Building Outside Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Aluminium Sheet Plate AA3003 for Building Outside Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Sheet Plate AA3003 for Building Outside Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

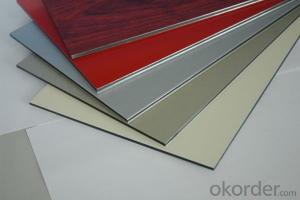

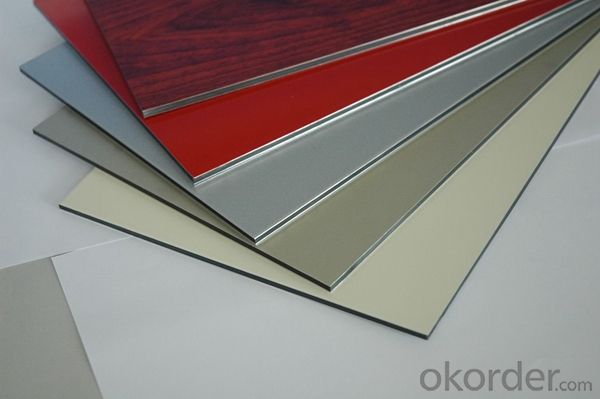

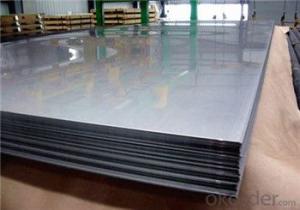

5. Image of Aluminium Sheet Plate AA3003 for Building Outside Wall

6. Package and shipping of Aluminium Sheet Plate AA3003 for Building Outside Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the standard sizes of aluminum sheets?

- The standard sizes of aluminum sheets can vary depending on the manufacturer and specific requirements. However, some commonly available standard sizes for aluminum sheets include 4 feet by 8 feet (1.2 meters by 2.4 meters), 4 feet by 10 feet (1.2 meters by 3 meters), and 5 feet by 10 feet (1.5 meters by 3 meters). These sizes are widely used in various industries and are readily available in the market. Additionally, custom sizes can also be obtained through specialized aluminum sheet suppliers to meet specific project needs.

- Q: Are 101 aluminum sheets suitable for marine environments?

- No, 101 aluminum sheets are not suitable for marine environments as they lack sufficient corrosion resistance.

- Q: What are the different methods of surface coating for aluminum sheets?

- There are several methods of surface coating for aluminum sheets, including anodizing, powder coating, painting, and laminating.

- Q: why can't aluminum sheet burn after polishing?

- because aluminum will rapidly formulate dense oxide film once being exposed in air, oxide film will generate after polishing, it can't burn.

- Q: How do i prepare the aluminium sheet to paint with oils on it?Do I have to buy special aluminium or any kind will work?

- Any aluminium will do. Sandpaper it 3 times with decreasingly coarse grain papers, clean it thoroughly with turpentine and then apply 3 coats of white oil based paint. Gesso would do too, but you'd have to use more layers

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- There are two methods: 1 AB glue or epoxy resin adhesive. 2. If the thickness of the two plate is greater than 8MM, it can be fixed by flat screw. Hope to be available.

- Q: How do you prevent fingerprints on aluminum sheets?

- To prevent fingerprints on aluminum sheets, there are a few strategies you can employ: 1. Wear gloves: One of the easiest ways to avoid leaving fingerprints on aluminum sheets is to wear gloves while handling them. This will create a barrier between your hands and the surface, preventing any marks or smudges. 2. Clean the surface: Before handling aluminum sheets, make sure to clean the surface thoroughly. Use a suitable cleaning agent or a mild detergent to remove any dirt or oils that may be present. Dry the sheets completely with a lint-free cloth to minimize the chances of fingerprints sticking to the surface. 3. Use a protective coating: Applying a protective coating on the aluminum sheets can help prevent fingerprints. There are several options available, such as clear lacquer or a clear protective film specifically designed for this purpose. These coatings create a barrier that reduces the visibility of fingerprints and makes them easier to clean off. 4. Handle with care: When handling aluminum sheets, try to touch them as little as possible. Fingerprints are more likely to occur when you apply pressure or touch the surface repeatedly. If possible, use tools or gloves to manipulate the sheets instead of direct contact with your hands. 5. Store properly: Proper storage of aluminum sheets is crucial in preventing fingerprints. Ensure that they are stored in a clean and dust-free environment, away from any potential contaminants. Consider using protective sleeves or covers to shield the sheets from fingerprints and other marks. By employing these preventive measures, you can significantly reduce the occurrence of fingerprints on aluminum sheets, keeping them clean and visually appealing.

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- The color of aluminum sheet is single, the quality is not high; the price of stone is high; the color difference is serious; the radiation is not environmental; and the resource is limited; the supply is difficult to guarantee; the weight of the tile is light; the radiation is zero; the pollution resistance is strong. Rich in color, especially in the production process, forms of diversification, to meet high, medium and low-end customer base needs. Zhejiang ruigao company is China and Asia's first introduction of the ceramic plate production line, their R & D capability is recognized. The pursuit of perfection, the introduction of new ideas, and the concept of customization for architects to realize their dreams and fashion designs for the architecture have opened wider space for the wide application of ceramic panels and curtain walls. In fact, the application of ceramic is not limited to curtain wall, but also applied to the lighting effect display, interior decoration and so on. Hi! In short, there are any problems can be exchanged with each other.

- Q: What's the difference between laser cutting aluminum plate and stainless steel plate?

- Aluminum plate reflectivity high, viscous strong, general 3mm above will hang slag, but very easy to peel off, stainless steel cutting ability and thickness and equipment power relationship more.Wire cutting: wire cutting refers to WEDM. It is developed on the basis of electric spark piercing and forming. In some ways, WEDM has been replaced by edm. Need to use the electric spark line cutting machine operation line cutting, the basic physical principle is free of positive ions and electrons in the presence of accumulation, a conductive channel ionized quickly formed, current formed between two plates, caused numerous collisions between particles, the formation of a plasma, and quickly rises to the high temperature of 8000 to 12000 the moment in the two conductor surface melting materials.

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets can be used in aerospace industries. Aluminum is commonly used in the aerospace industry due to its lightweight, high strength-to-weight ratio, and corrosion resistance properties. It is used for various applications such as aircraft structures, wings, fuselages, and skins.

Send your message to us

Aluminum Sheets New York - Aluminium Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords