Color Coated Aluminium Sheet AA3003 for ACP Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminium Sheet AA3003 for ACP Panel

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Color Coated Aluminium Sheet AA3003 for ACP Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Sheet AA3003 for ACP Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

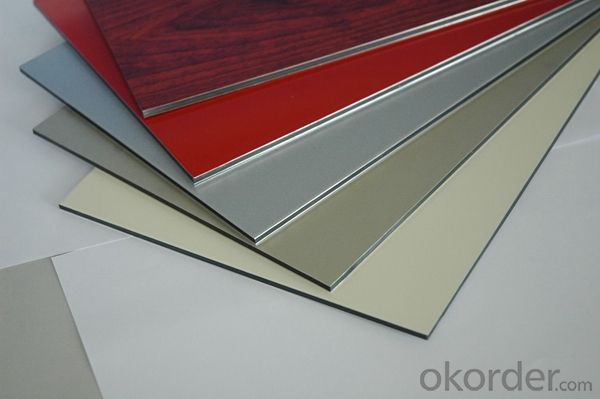

5. Image of Color Coated Aluminium Sheet AA3003 for ACP Panel

6. Package and shipping of Color Coated Aluminium Sheet AA3003 for ACP Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the main influence of the spacing?What are the main effects of spacing?

- Thermal explosion is related to a lot of factors. As to how much impact the lining board has on the thermal explosion, it's really impossible to speak of it. I think it has very little influence

- Q: What are the different types of patterns available for aluminum sheets?

- There are several different types of patterns available for aluminum sheets, including diamond, tread, stucco, and perforated. Each pattern offers unique aesthetic and functional properties, catering to various applications and design preferences.

- Q: Can aluminum sheets be used for reflective purposes?

- Yes, aluminum sheets can be used for reflective purposes due to their high reflectivity and low absorption of light.

- Q: What are the different grades of aluminum sheets available?

- There are several different grades of aluminum sheets available, including 1100, 3003, 5052, and 6061. These grades vary in terms of their composition, strength, and intended use. 1100 aluminum is the most commercially pure grade and is often used for general purpose applications. 3003 aluminum is alloyed with manganese and has improved strength and corrosion resistance. 5052 aluminum is alloyed with magnesium and has excellent weldability and formability. 6061 aluminum is alloyed with magnesium and silicon and is known for its high strength and versatility.

- Q: Can aluminum sheet be used for electrical enclosures?

- Indeed, electrical enclosures can indeed utilize aluminum sheet. The remarkable conductivity, lightweight composition, and resistance to corrosion render aluminum a favored option for electrical enclosures. It effectively safeguards against electromagnetic interference and possesses commendable heat dissipation properties. Moreover, aluminum boasts malleability, enabling the production of intricate shapes and designs. In summary, aluminum sheet is a fitting material for electrical enclosures and finds widespread application in diverse industries like electronics, telecommunications, and power distribution.

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: Can 101 aluminum sheets be recycled?

- Yes, 101 aluminum sheets can be recycled.

- Q: This question asks for methods to determine the thickness of aluminum sheets.

- <p>To measure the thickness of aluminum sheets, you can use various methods including mechanical thickness gauges, ultrasonic thickness gauges, or calipers. Mechanical gauges are simple and involve sliding a foot along the sheet until it bottoms out on both sides. Ultrasonic thickness gauges use sound waves to measure thickness and are non-destructive, providing accurate measurements. Calipers can also be used for manual measurement, though they may be less precise for very thin sheets. Always ensure the measuring device is calibrated and suitable for the material and thickness range of the aluminum sheet in question.</p>

- Q: Are the aluminum sheets suitable for manufacturing heat exchanger tubes?

- Yes, aluminum sheets are suitable for manufacturing heat exchanger tubes. Aluminum has excellent thermal conductivity, corrosion resistance, and is lightweight, making it an ideal material for heat transfer applications.

- Q: What are the applications of aluminum sheet?

- Due to their unique properties and versatility, aluminum sheets have a wide range of applications. Some common uses include: 1. Construction: In the construction industry, aluminum sheets are widely utilized for roofing, siding, and cladding purposes. Their lightweight nature allows for easy handling and installation, while their corrosion resistance ensures durability over time. 2. Transportation: Aluminum sheets play a crucial role in the automotive industry by being extensively used in manufacturing vehicle bodies, panels, and structural components. Their high strength-to-weight ratio helps reduce overall vehicle weight, leading to increased fuel efficiency and improved performance. 3. Packaging: Within the packaging industry, aluminum sheets are commonly employed in the production of cans, foils, and containers. Aluminum foils, in particular, are utilized for food packaging as they provide a protective barrier against moisture, light, and oxygen, ensuring the freshness and safety of packaged products. 4. Electrical: The electrical industry relies on aluminum sheets for manufacturing power transmission lines, busbars, and electrical enclosures. Their excellent electrical conductivity aids in the efficient transmission of electricity, while their corrosion resistance allows for longevity in outdoor applications. 5. Marine: The marine industry extensively utilizes aluminum sheets for manufacturing boat hulls, decks, and superstructures. Their resistance to corrosion from saltwater makes them ideal for marine applications, and their lightweight nature helps reduce overall vessel weight. 6. Aerospace: In the aerospace industry, aluminum sheets are widely used for manufacturing aircraft and spacecraft components. Their high strength-to-weight ratio and excellent thermal conductivity make them suitable for applications where weight reduction and heat dissipation are critical. 7. Heat exchangers: Aluminum sheets are crucial in the manufacturing of heat exchangers, such as radiators and condensers. Their high thermal conductivity allows for efficient heat transfer, making them ideal for applications that require heat exchange. 8. Decorative: Aluminum sheets also find common use in interior design and architectural applications for decorative purposes. They can be easily shaped, bent, and formed into various designs, adding a modern and aesthetic appeal to buildings and interiors. In summary, aluminum sheets are extensively utilized in various industries due to their lightweight nature, corrosion resistance, high strength-to-weight ratio, and excellent thermal conductivity.

Send your message to us

Color Coated Aluminium Sheet AA3003 for ACP Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords