COLD ROLLED WAVE GALVANIZED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

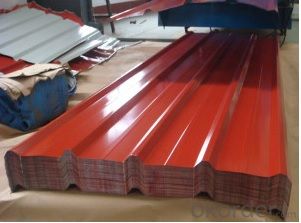

COLD ROLLED WAVE GALVANIZED STEEL SHEET

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What are the different surface plating methods for steel strips?

- There are several different surface plating methods for steel strips, including electroplating, hot-dip galvanizing, electroless plating, and mechanical plating.

- Q: Can steel strips be used in the production of kitchen appliances?

- Yes, steel strips can be used in the production of kitchen appliances. Steel is a common material used in the manufacturing of kitchen appliances due to its durability, strength, and resistance to heat and corrosion. Steel strips can be formed into various components and parts such as panels, frames, and shelves, making them suitable for use in kitchen appliances like ovens, refrigerators, and dishwashers.

- Q: Can the tension leveller eliminate the wave shape of strip steel completely?

- Reflecting the shape of the board, the wave height is reduced or the wavelength is lengthened. That is, the tension straightener can only reduce the wave and improve the shape of the plate, but can not fundamentally eliminate the wave, and get an ideal smooth strip steel. There is an old saying called "correction must be positive". That is to completely eliminate the wave must be of short fiber than long fiber tension and bending is greater, elastic and plastic deformation of the original long fiber length is greater than a certain amount, resulting in the removal of external force, elastic recovery, length of fiber length, so as to obtain the shape completely flat the. However, in the current conditions of the straightening machine equipment, do not have such a function.

- Q: What are the environmental impacts of steel strip production?

- The production of steel strips has several environmental impacts. Firstly, the extraction of iron ore, the primary raw material for steel production, often involves open-pit mining or underground mining, which can lead to deforestation, habitat destruction, and soil erosion. Additionally, the mining process requires large amounts of water, potentially depleting local water sources and causing water pollution through the discharge of heavy metals and other contaminants. The next step in steel strip production involves converting iron ore into steel through a process called smelting. This process requires significant amounts of energy, usually derived from fossil fuels, leading to greenhouse gas emissions and contributing to climate change. The burning of fossil fuels also releases air pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter, which can have adverse effects on air quality, human health, and ecosystems. Furthermore, during the steel strip production process, various chemicals and additives are often used, including limestone, coke, and coal tar. These substances can contaminate water and soil if not properly managed, posing risks to aquatic life and potentially entering the food chain. The disposal of waste generated during steel production, such as slag and scale, can also have environmental impacts. Slag, a byproduct of the smelting process, is often dumped in landfills, taking up valuable space and potentially leaching harmful substances into the surrounding soil and groundwater. Lastly, the transportation of iron ore, coal, and other materials required for steel strip production contributes to carbon emissions from the burning of fossil fuels in transportation vehicles. To mitigate these environmental impacts, efforts are being made to improve the efficiency of steel production processes, reduce energy consumption, and increase the use of renewable energy sources. Recycling steel is another important strategy to minimize the environmental footprint of steel strip production, as it reduces the need for raw materials extraction and energy-intensive smelting processes. Additionally, implementing proper waste management practices and treating wastewater from steel mills can help minimize pollution risks.

- Q: How are steel strips processed for precision cutting?

- Steel strips are processed for precision cutting through a series of steps that involve careful planning, material selection, and the use of specialized cutting equipment. The process typically starts with the selection of the appropriate steel grade and thickness based on the specific requirements of the application. Once the steel strips are received, they are inspected for any defects or imperfections that could affect the cutting process. This step ensures that only high-quality materials are used for precision cutting. After inspection, the strips are usually cleaned to remove any contaminants that may have accumulated during storage or transportation. The next step involves the actual cutting of the steel strips. Precision cutting is achieved using advanced cutting equipment such as laser cutters or water jet machines. These machines are capable of producing highly accurate and clean cuts, ensuring that the final product meets the required specifications. During the cutting process, it is essential to maintain proper alignment and positioning of the steel strips. This is typically achieved through the use of clamps, jigs, or fixtures that securely hold the material in place. Precision cutting also requires a high level of control over cutting speed, feed rate, and cutting parameters to achieve the desired results. After the cutting process is complete, the steel strips may undergo additional treatments or finishing processes depending on the specific application. This can include deburring, surface grinding, or heat treatment to improve the overall quality and performance of the final product. In summary, steel strips are processed for precision cutting by carefully selecting the appropriate material, inspecting for defects, and using specialized cutting equipment. The process requires meticulous planning and attention to detail to ensure accurate and clean cuts that meet the required specifications.

- Q: What is the typical lifespan of steel strips?

- The typical lifespan of steel strips can vary greatly depending on various factors such as the quality of the steel, environmental conditions, and usage patterns. However, with proper care and maintenance, steel strips can last anywhere from several years to several decades.

- Q: What are the common dimensions for steel strips?

- The common dimensions for steel strips can vary depending on the specific application and industry. However, some commonly used dimensions for steel strips include thicknesses ranging from 0.005 inches to 0.625 inches and widths ranging from 0.25 inches to 12 inches.

- Q: What is the hardness of a steel strip?

- The hardness of a steel strip refers to its ability to resist deformation or indentation. It is commonly measured using scales such as the Rockwell Hardness Scale or the Brinell Hardness Scale. The specific hardness of a steel strip can vary depending on factors such as its composition, heat treatment, and manufacturing process. Steel strips with a higher hardness are typically more resistant to wear and can withstand higher loads, making them suitable for applications that require durability and strength, such as in automotive components, tools, or machinery parts.

- Q: How are steel strips coated with a protective oil film?

- Steel strips are coated with a protective oil film through a process called oiling or oil coating. In this process, the steel strips are passed through a coating line where they are immersed in an oil bath or sprayed with oil. The oil forms a thin film on the surface of the steel, providing a protective layer that helps prevent corrosion and oxidation. This oil film also acts as a lubricant, making it easier to handle and process the steel strips during subsequent manufacturing operations.

- Q: How to distinguish cold strip steel and cold rolled silicon steel sheet by simple and practical methods?

- A little further, to buy a measuring instrument of iron loss, the general cold strip can replace the silicon steel sheet, especially low grade such as 1300 and so on, the loss reached 13, low demand can be used instead of cold rolled strip steel production, little more.

Send your message to us

COLD ROLLED WAVE GALVANIZED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords